Environment-friendly heat insulation and sound insulation compound brick

A technology of heat insulation and sound insulation, heat insulation and sound insulation layer, applied in the direction of building materials, etc., can solve the problems of practical use limitations, insufficient structural strength to resist violent shaking, and discounted heat preservation and cold resistance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044]The present invention provides an environmentally friendly heat-insulating and sound-insulating composite brick, which includes a heat-insulating and sound-insulating layer, a first brick layer and a second brick layer, wherein the first brick layer is integrally formed on one side of the heat-insulating and sound-insulating layer , while the second brick layer is also integrally combined with the other side of the heat and sound insulation layer.

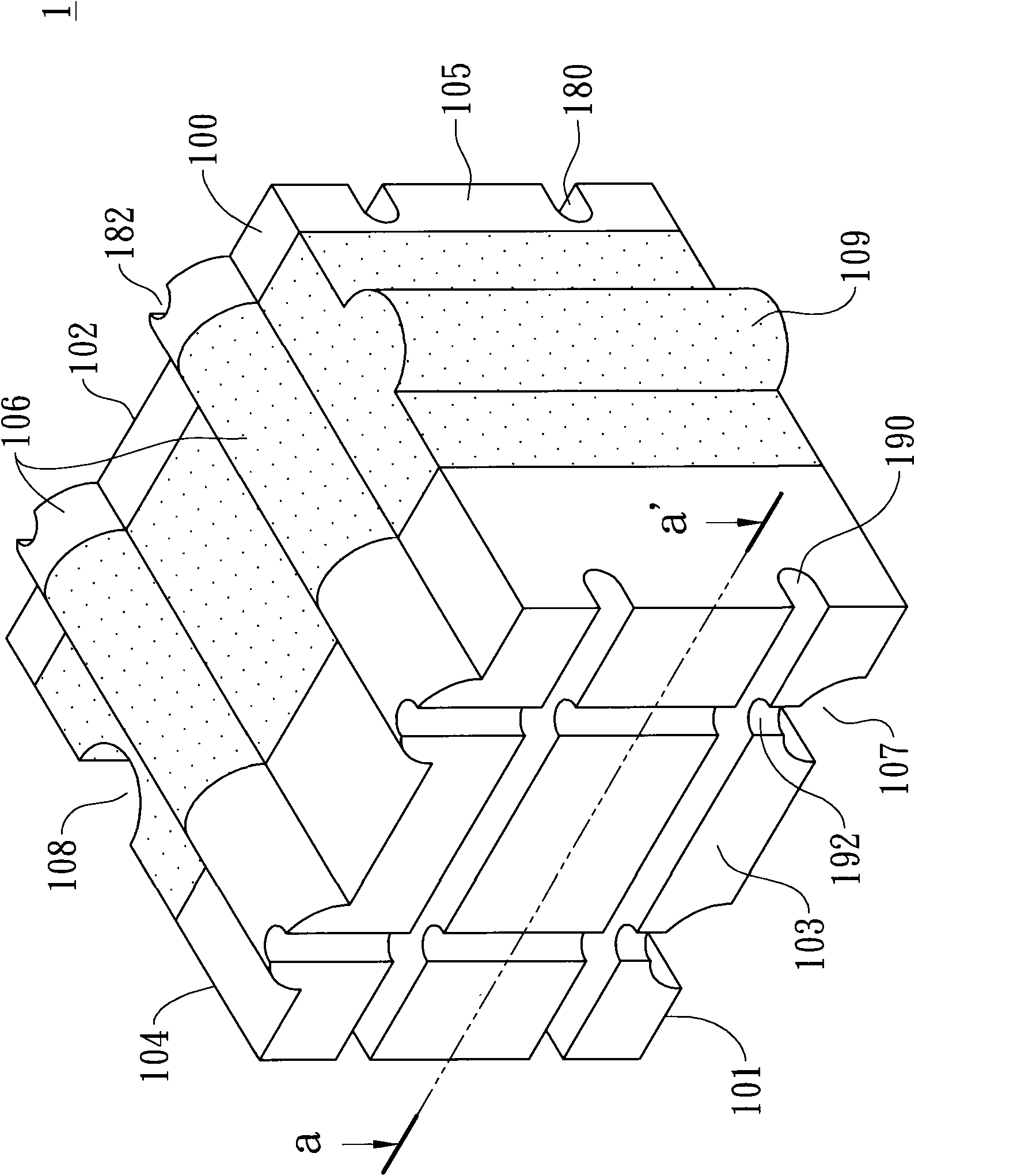

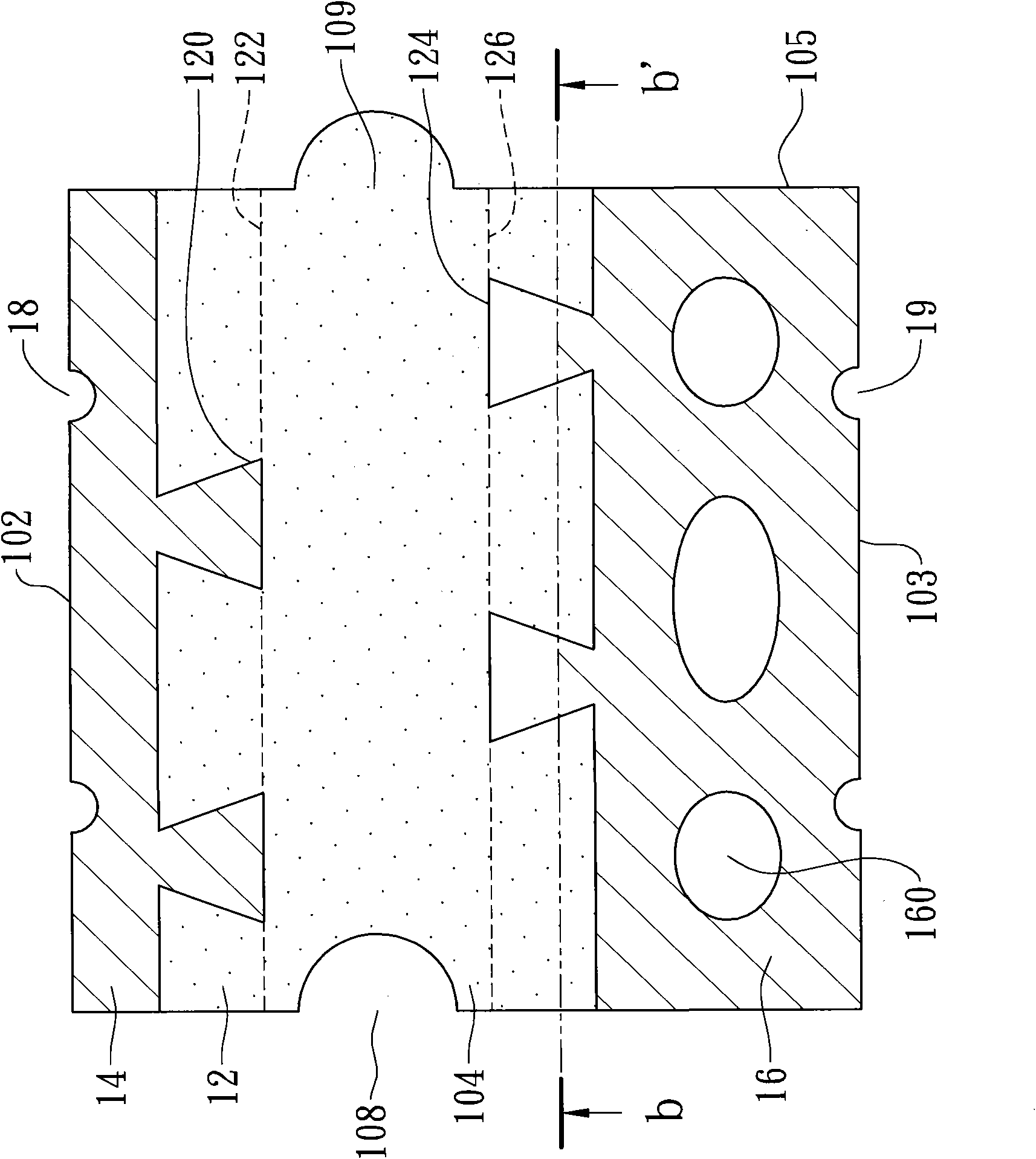

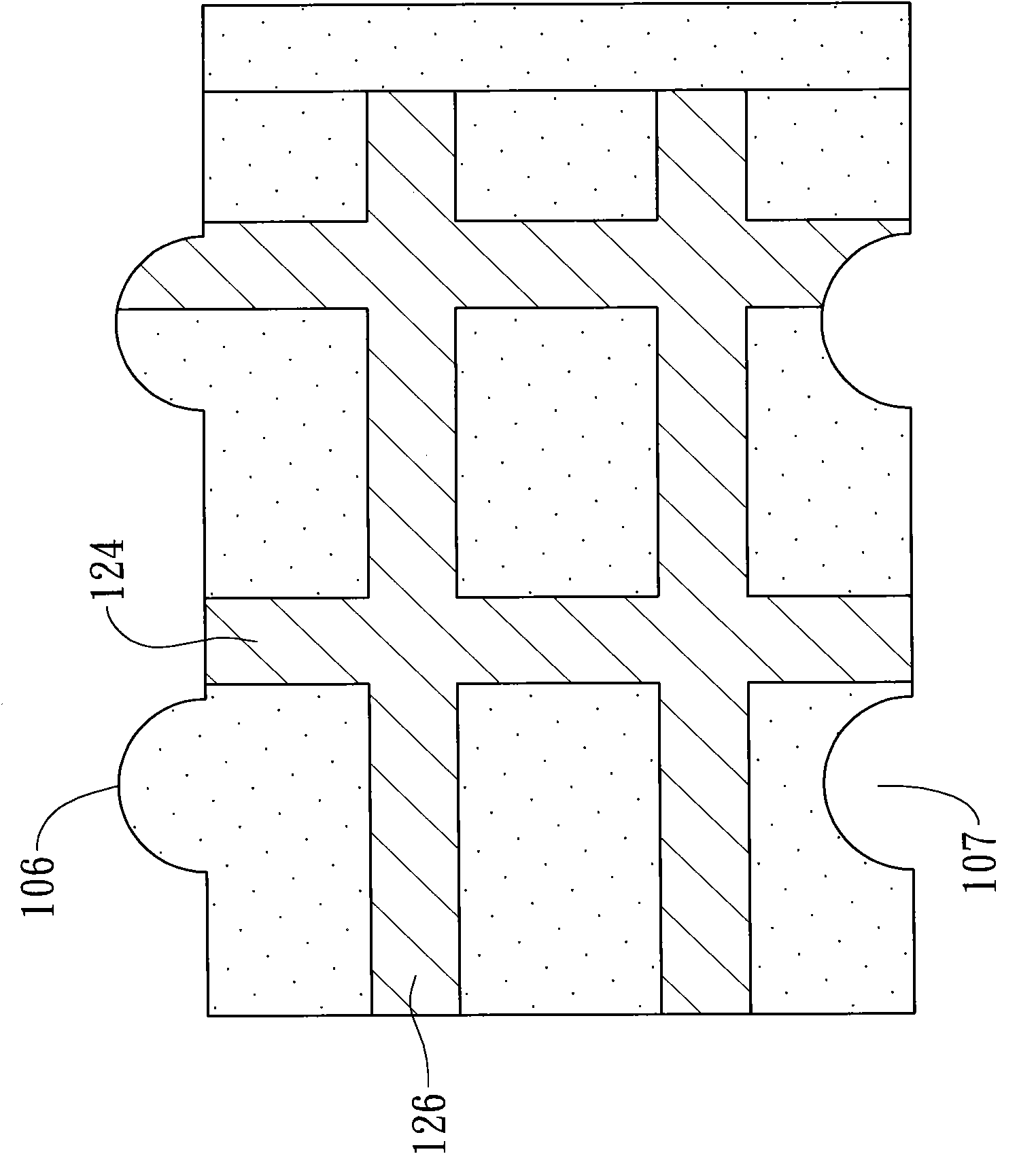

[0045] see Figure 1 to Figure 3 , which shows the first embodiment of the environmental protection heat insulation and sound insulation composite brick of the present invention. In this embodiment, the environmentally friendly heat-insulating and sound-insulating composite brick 1 is a rectangular block; the rectangular block defines a top surface 100, a bottom surface 101, an outer surface 102, an inner surface 103, a left side 104 and A right side 105 is composed of a heat and sound insulation layer 12 , a first and a sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com