Supported metallocene catalyst and olefin polymer, and preparation methods thereof

A metallocene catalyst and metallocene compound technology are applied in the field of supported metallocene catalysts and olefin polymers and their preparation, which can solve the problems of high price and low polyolefin bulk density, and achieve the effect of reducing the preparation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention also provides a preparation method of the above-mentioned supported metallocene catalyst, the method comprising: under the protection of an inert gas, sequentially supporting the alkylaluminoxane and the metallocene compound on the carrier.

[0034] The method for preparing a supported metallocene catalyst according to the present invention, wherein the method further includes heating the carrier at a temperature of 300-900° C. for 7 hours under the protection of an inert gas before loading the alkylaluminoxane -30 hours.

[0035]According to the preparation method of the supported metallocene catalyst of the present invention, the supported method can be determined according to the well-known content in the field of olefin polymerization catalyst preparation, the present invention is not particularly limited, for example, a preferred supported method includes the following step:

[0036] The first step is to prepare an activated support: under th...

preparation Embodiment 1

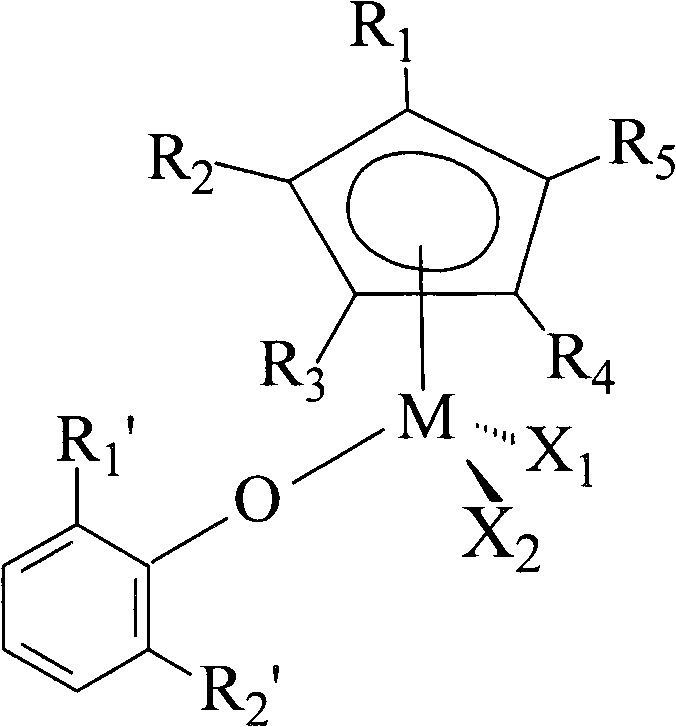

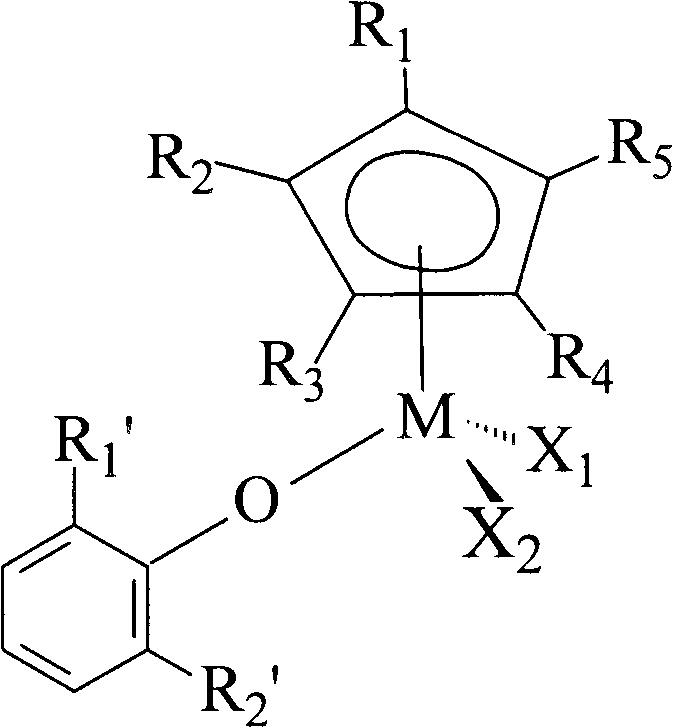

[0054] This preparation example is used for preparing R in formula 1 1 , R 2 , R 3 , R 4 and R 5 is methyl and R 1 ’ and R 2 ' is the metallocene compound of isopropyl group.

[0055] Two well-dried 250 ml three-neck flasks were placed in an ice bath and fully replaced with nitrogen three times. Add 1.78 grams of 2,6-diisopropylphenol and 50 milliliters of dry toluene to one of the three-necked flasks, stir until fully dissolved, then slowly add 4.2 milliliters of 2.5 mol / L concentration of butyllithium in hexane within 10 minutes solution. After the dropwise addition was completed, the ice bath was removed, and the reaction was stirred at room temperature for 4 hours to obtain a reaction liquid after the reaction of 2,6-diisopropylphenol and butyllithium. Add 2.89 grams of pentamethylcyclopentadienyl titanium trichloride (purchased from Strem Company) to another three-necked bottle, add 50 ml of dry tetrahydrofuran, start stirring, after fully dissolving, slowly add t...

preparation Embodiment 2

[0057] This preparation example is used for preparing R in formula 1 1 , R 2 , R 3 , R 4 and R 5 is methyl and R 1 ’ and R 2 ' is a metallocene compound of phenyl group.

[0058] Two well-dried 250 ml three-neck flasks were placed in an ice bath and fully replaced with nitrogen three times. Add 2.48 grams of 2,6-diphenylphenol and 50 milliliters of dry toluene to one of the three-necked flasks, stir until fully dissolved, then slowly add 4.2 milliliters of 2.5 mol / L hexane solution of butyllithium in 10 minutes . After the dropwise addition was completed, the ice bath was removed, and the reaction was stirred at room temperature for 4 hours to obtain a reaction liquid after the reaction of 2,6-diisopropylphenol and butyllithium. Add 2.89 g of pentamethylcyclopentadienyl titanium trichloride to another three-necked flask, add 50 ml of dry tetrahydrofuran, start stirring, and after fully dissolving, slowly add 2,6-diphenylphenol and butyl The reaction solution after lit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com