Method for recycling sodium sulfate from waste alkali liquor of ethylene unit

A technology of waste ethylene lye and sodium sulfate, which is applied in the directions of alkali metal sulfite/sulfite, chemical instruments and methods, alkali metal compounds, etc. Operation and other issues to achieve the effect of reducing salt content, avoiding shocks, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

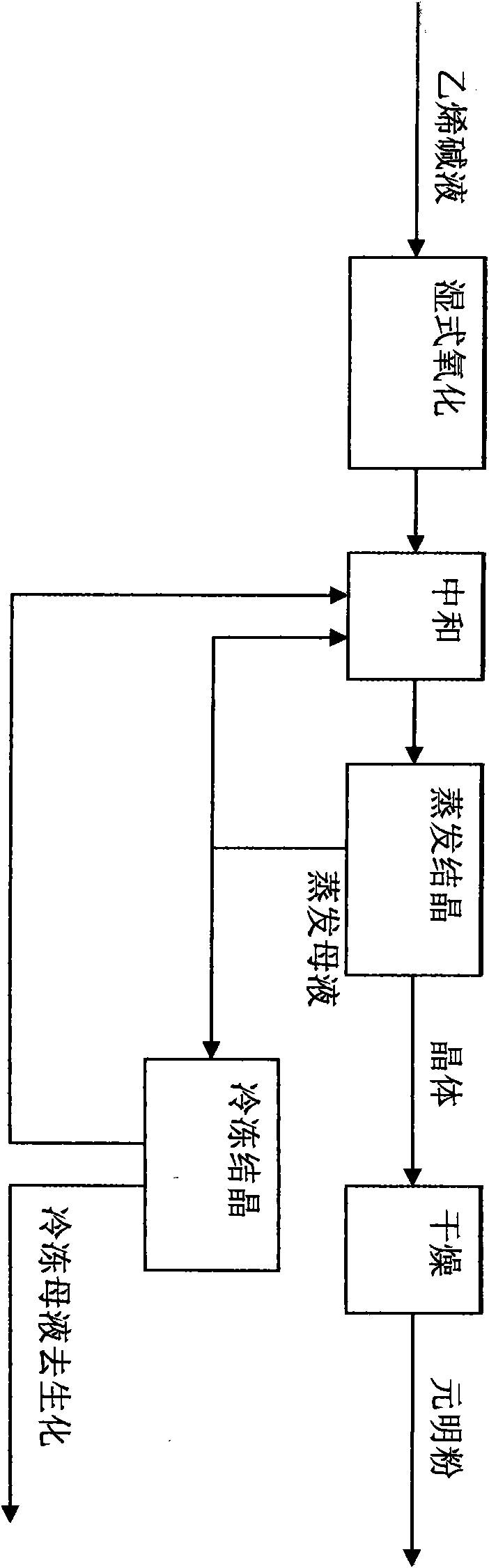

Method used

Image

Examples

Embodiment 1

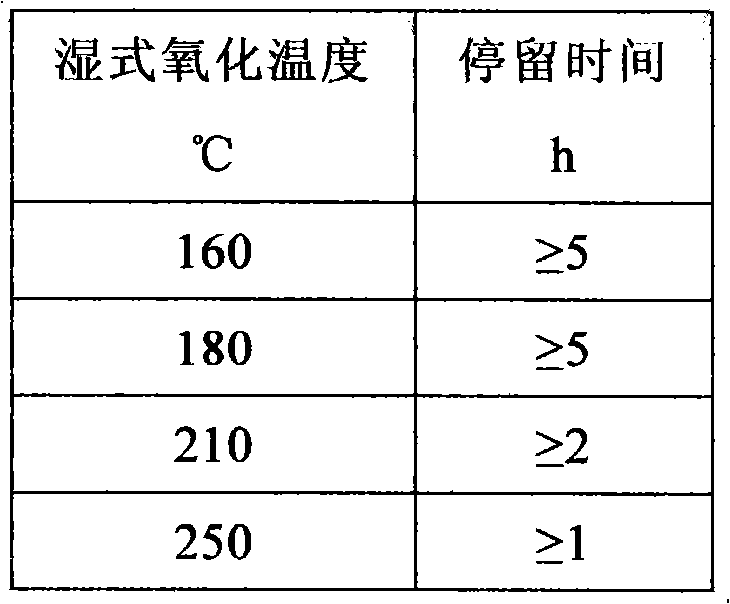

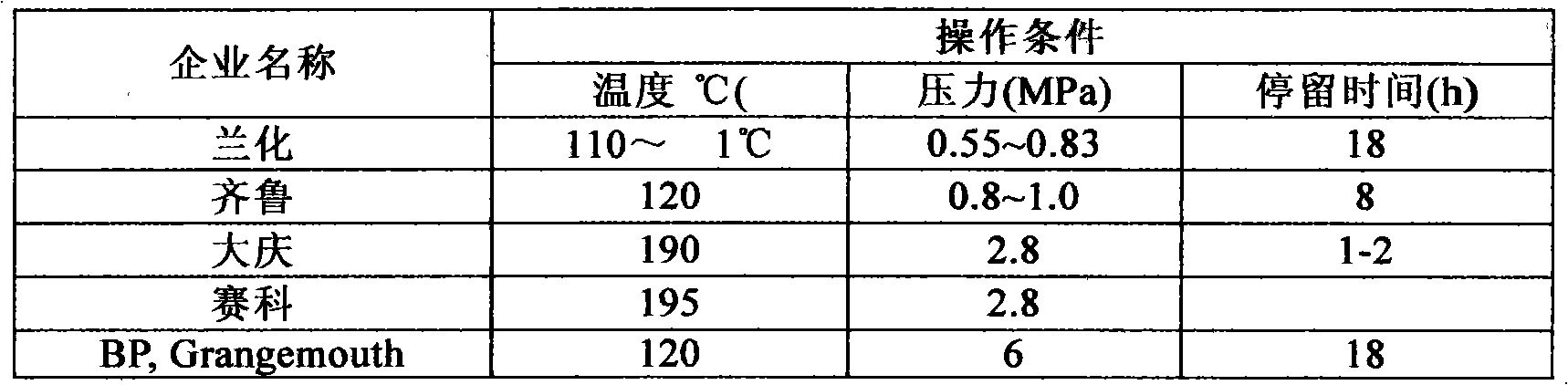

[0051] The ethylene spent lye was oxidized in wet air at 160°C (6MPa) for 5 hours without dilution and pH adjustment, and the resulting oxidized solution was neutralized to pH 4.64 with concentrated sulfuric acid, and the neutralized solution was crystallized by vacuum evaporation. Dried into Yuanming powder, part of the mother liquor is evaporated to freeze and crystallize, the freeze crystal is returned to the neutralization unit, and the frozen mother liquor is removed for biochemical treatment. Part of the evaporated mother liquor is returned to the neutralization unit to reduce the content of sodium carbonate and increase the yield of qualified products. The sodium sulfate content of the obtained sodium sulfate is 97.05%, which meets the "GB-T 6009-2003 Industrial Anhydrous Sodium Sulfate" Class II qualified product standard; the amount of the obtained frozen mother liquor is reduced to about 1 / 20 of the neutralization liquid amount, and the COD is 2800mg / L, total dissol...

Embodiment 2

[0054] The ethylene spent lye was oxidized in wet air at 180°C (6MPa) for 5 hours without dilution and pH adjustment, and the resulting oxidized solution was neutralized to pH 4.01 with concentrated sulfuric acid, and the neutralized solution was crystallized by vacuum evaporation. Dried into Yuanming powder, part of the mother liquor is evaporated to freeze and crystallize, the freeze crystal is returned to the neutralization unit, and the frozen mother liquor is removed for biochemical treatment. Part of the evaporated mother liquor is returned to the neutralization unit to reduce the content of sodium carbonate and increase the yield of qualified products. The sodium sulfate content of the obtained sodium sulfate is 97.12%, which meets the standard of "GB-T 6009-2003 Industrial Anhydrous Sodium Sulfate" Class II qualified products; L, total dissolved solids 6%.

Embodiment 3

[0056] The ethylene spent lye was subjected to wet oxygen oxidation at 210°C (6MPa) for 2 hours without dilution and pH adjustment, and the resulting oxidized solution was neutralized to pH 4.70 with concentrated sulfuric acid, and the neutralized solution was crystallized by vacuum evaporation. Dried into Yuanming powder, part of the mother liquor is evaporated to freeze and crystallize, the freeze crystal is returned to the neutralization unit, and the frozen mother liquor is removed for biochemical treatment. Part of the evaporated mother liquor is returned to the neutralization unit to reduce the content of sodium carbonate and increase the yield of qualified products. The sodium sulfate content of the obtained sodium sulfate is 97.13%, which meets the standard of "GB-T 6009-2003 Industrial Anhydrous Sodium Sulfate" Class II qualified products; L, total dissolved solids 6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com