Metal plate forming device

A metal plate and metal plate technology, which is applied in the field of metal plate forming devices, can solve problems such as incomplete molding of blanks, poor flow channel size accuracy, and high thinning rate of bipolar plates, so as to avoid spark discharge, The effect of simple structure, low resistance and inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to have a clearer understanding of the technical features, objects and effects of the present invention, the specific embodiments of the present invention will now be described with reference to the accompanying drawings.

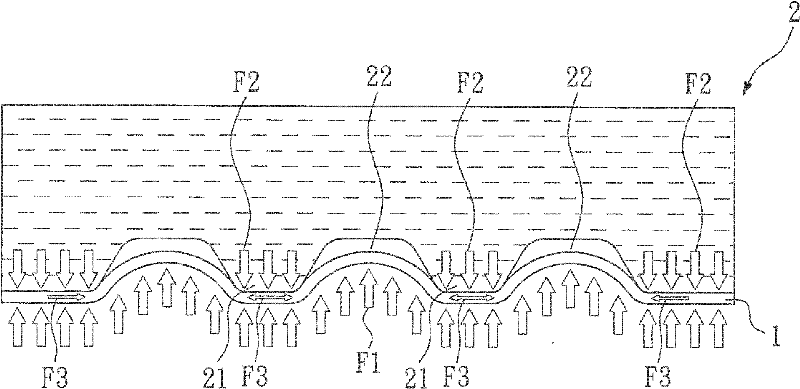

[0032] figure 2 A schematic diagram showing a first embodiment of the sheet metal forming apparatus of the present invention; image 3 A schematic diagram showing a first embodiment of the plate-shaped electromagnetic coil of the present invention. mate reference figure 2 and image 3 , the sheet metal forming device 3 includes a mold 30 and an electromagnetic generating device 40 . The mold 30 has a forming surface 31 , and the forming surface 31 has a pattern structure 311 . The pattern structure 311 includes at least one high portion 312 and at least one low portion 313 . In this embodiment, the pattern structure 311 includes a plurality of high portions (protrusion structures) 312 and a plurality of low portions (groove structures)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com