Multi-point injection gas supply system for fuel gas generator set

A technology of generator set and gas supply system, applied in combustion engine, internal combustion piston engine, engine control and other directions, can solve the problems of large gas volume, waste, environmental pollution of harmful exhaust gas, etc., and achieve the effect of saving cost and saving gas consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, further illustrate the present invention through embodiment.

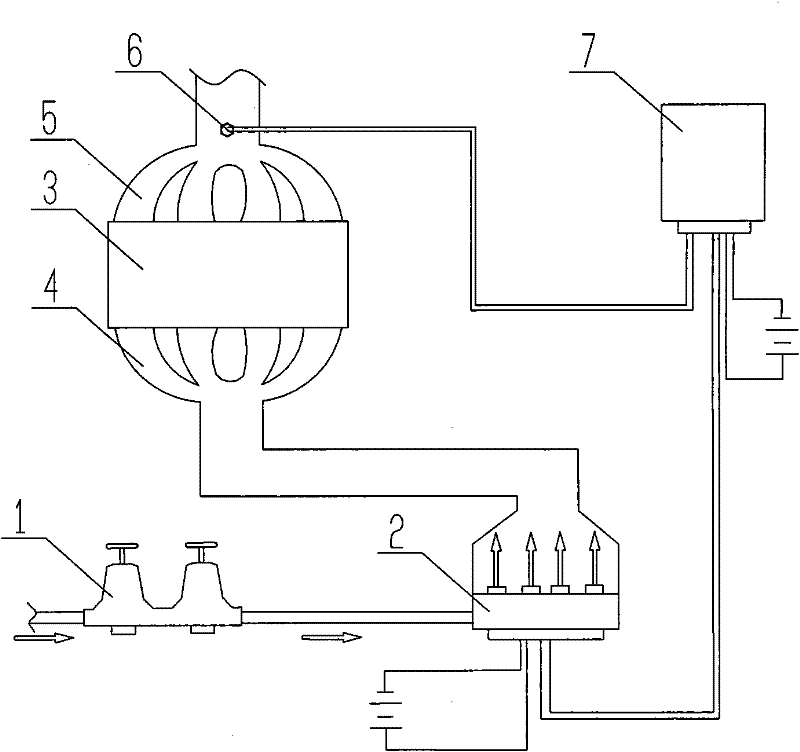

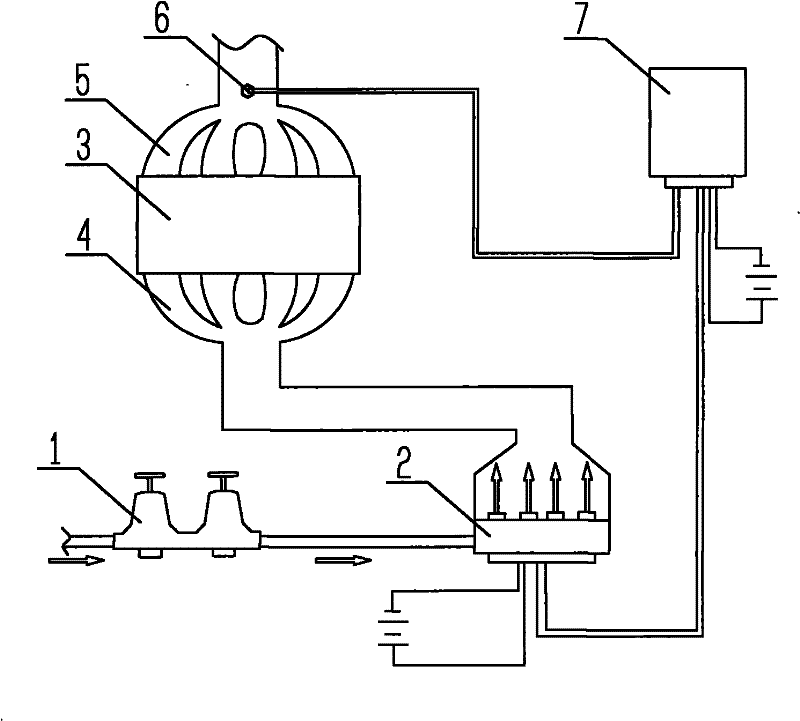

[0014] Such as figure 1 As shown, the multi-point injection gas supply system of the gas generator set according to the present invention includes a pressure reducing valve 1, a gas injection rail 2, a cylinder 3, an intake manifold 4, and an exhaust manifold 5, and the exhaust manifold 5 is provided with a wide-area oxygen sensor 6, and both the wide-area oxygen sensor 6 and the gas injection rail 2 are connected to a computer 7.

[0015] The gas enters the gas injection rail 2 after being decompressed by the pressure reducing valve 1, and enters the cylinder 3 through the intake manifold 3 according to the theoretical air-fuel ratio preset by the computer 7, and after burning in the cylinder 3, the exhaust gas generated At the same time, the wide-area oxygen sensor 6 detects the concentration of harmful substances at the exhaust gas channel, and sends the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com