High-density culture process of autotrophic oil-producing microalgae

A technology for high-density culture and oil-producing microalgae, which is applied in the high-density culture technology field of autotrophic oil-producing microalgae, can solve the problems of easily polluted bacteria and complex sewage components, and achieves high social and economic comprehensive benefits and comprehensive High efficiency and the effect of reducing greenhouse gas emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

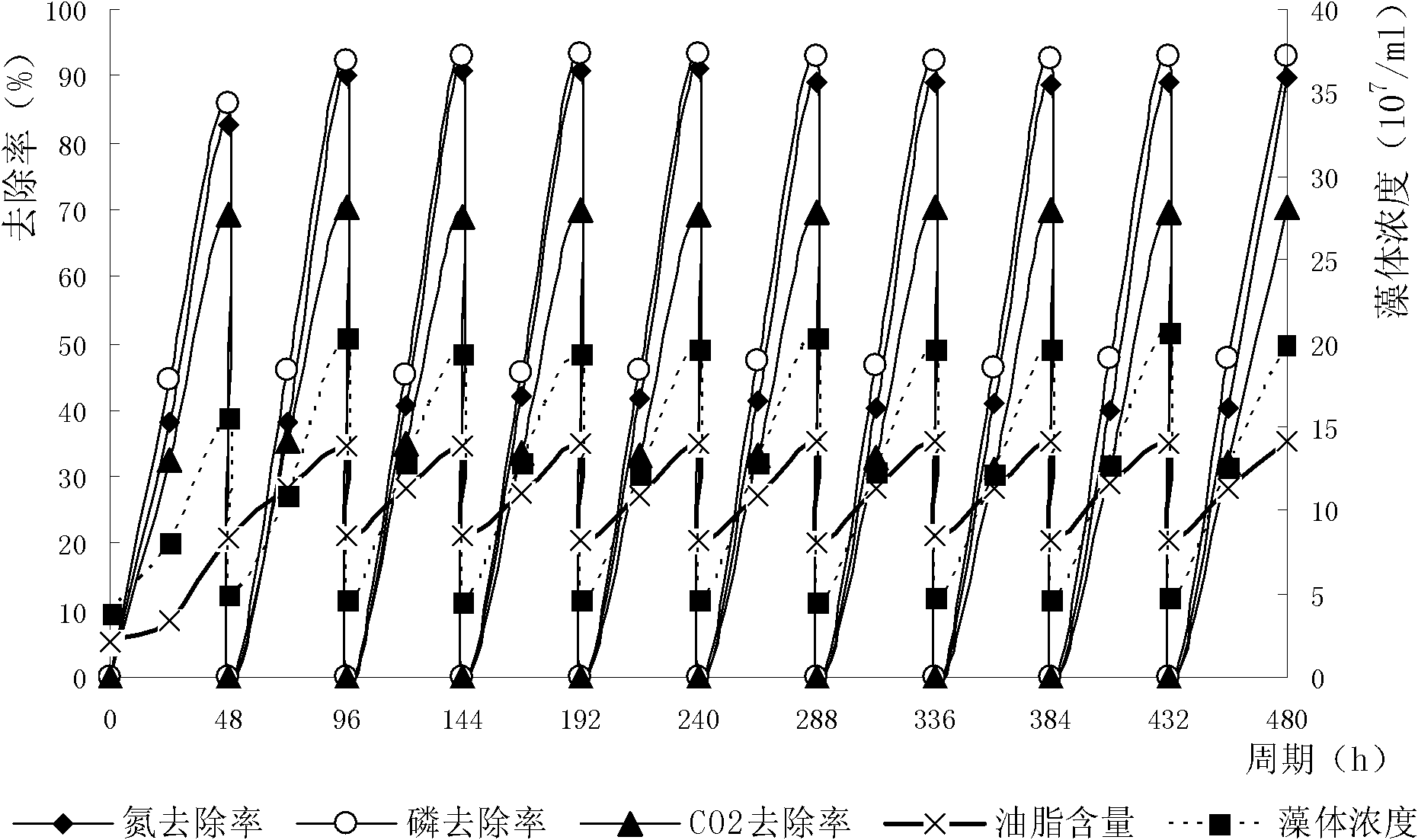

Embodiment 1

[0056] With the municipal sewage (nitrogen content 30.0mg / L, phosphorus content 5.0mg / L) after filtration to remove miscellaneous bacteria or miscellaneous algae as the culture medium, the concentration of cultured is 4.0×10 7 cfu / ml~3.0×10 8 A high concentration of cfu / ml Chlorella autotuophica (Chlorella autotuophica) was inoculated into the photoreactor, the inoculum amount was 40% (v / v), the culture temperature was 28°C, the pH was 7.0, the light cycle was 12h, and the light intensity was 10000lux, the CO emitted by the thermal power plant 2 Exhaust gas (CO 2 The concentration is 13.0% (v / v)) as the carbon source, and the ventilation rate is 0.2VVm. Before the split culture, after 48 hours of culture, the algae concentration in the photoreactor is as high as 1.5×10 8 cfu / ml, and when the content of nitrogen and phosphorus in the photoreactor is close to the national Class A discharge water standard, the fermentation broth is divided, and 1 / 3 to 2 / 3 of the fermentation br...

Embodiment 2

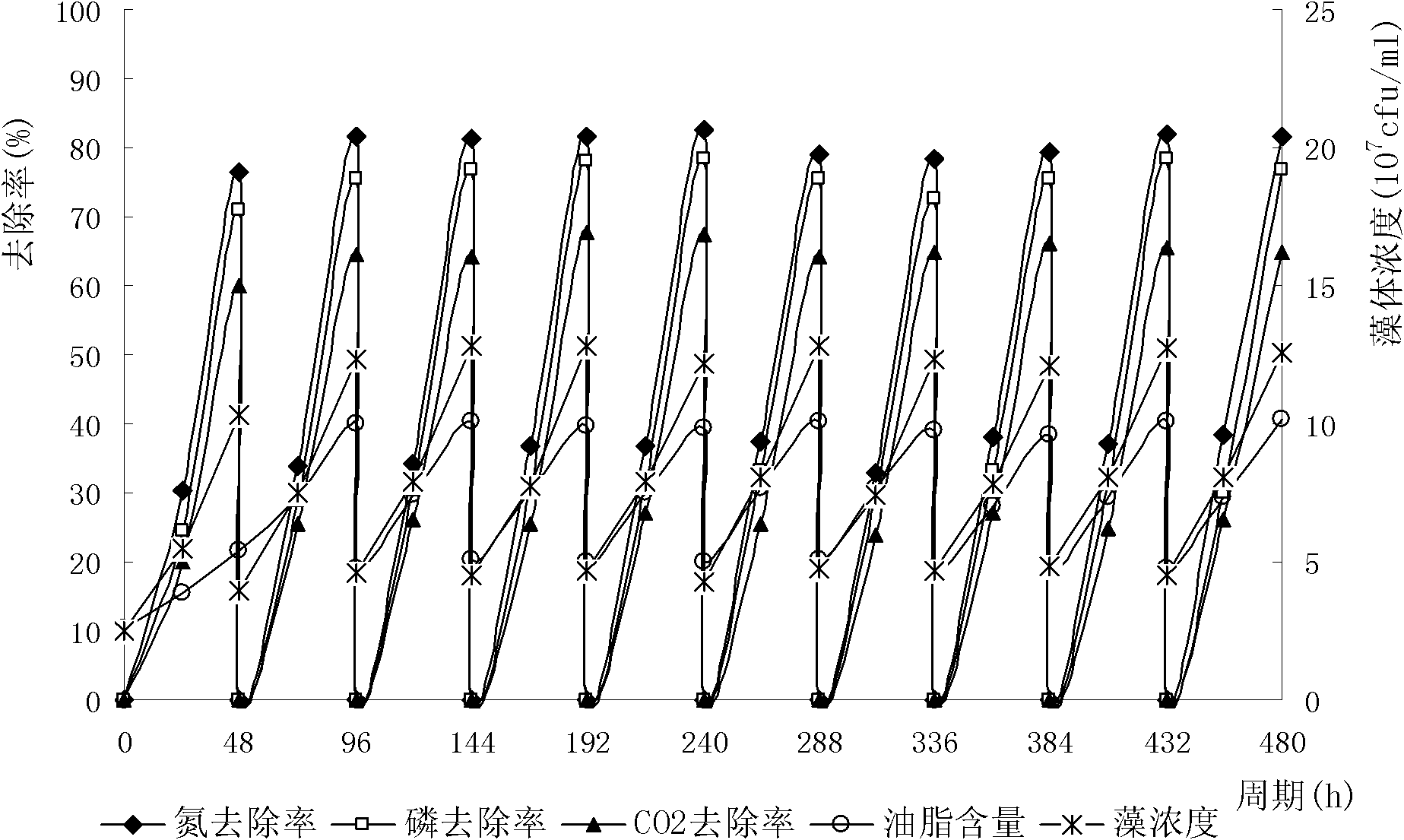

[0060] With the municipal sewage (nitrogen content 30.0mg / L, phosphorus content 5.0mg / L) after filtration to remove miscellaneous bacteria or miscellaneous algae as the culture medium, the concentration of cultured is 4.0×10 7 cfu / ml~3.0×10 8 The high concentration Nannochloropsis algae (Nannochloropsissalina) of cfu / ml was inoculated into the photoreactor, the inoculation amount was 20% (v / v), the culture temperature was 20°C, the pH was 8.5, the light cycle was 16h, and the light intensity was 15000lux , the CO emitted by thermal power plants 2 Exhaust gas (CO 2 The concentration is 20.0% (v / v)) as the carbon source, and the ventilation rate is 0.1VVm. Before the split culture, after 48 hours of culture, the algae concentration in the photoreactor is as high as 3.0×10 8 cfu / ml, and when the content of nitrogen and phosphorus in the photoreactor is close to the national Class A discharge water standard, the fermentation broth is divided, and 1 / 3 to 2 / 3 of the fermentation b...

Embodiment 3

[0064] With the municipal sewage (nitrogen content 30.0mg / L, phosphorus content 5.0mg / L) after filtration to remove miscellaneous bacteria or miscellaneous algae as the culture medium, the concentration of cultured is 4.0×10 7 cfu / ml~3.0×10 8 The high-concentration Brown botrytis (Botyococcus Braunii) of cfu / ml was inoculated into the photoreactor, the inoculum size was 60% (v / v), the culture temperature was 35°C, the pH was 6.5, the light cycle was 10h, and the light intensity was 5000lux. CO emissions from thermal power plants 2 Exhaust gas (CO 2 The concentration is 10.0% (v / v)) as the carbon source, and the ventilation rate is 0.01VVm. Before the split culture, after 48 hours of culture, the algae concentration in the photoreactor is as high as 1.0×10 8cfu / ml, and when the content of nitrogen and phosphorus in the photoreactor is close to the national Class A discharge water standard, the fermentation broth is divided, and 1 / 3 to 2 / 3 of the fermentation broth is taken ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com