Metal wiredrawing composite steel plate and preparation method thereof

A clad steel plate and metal wire drawing technology, applied in the field of metal clad steel plates, can solve the problems of complex lamination process and high production cost, and achieve the effects of low production cost, convenient operation and good application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

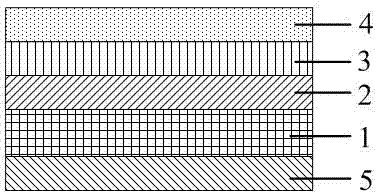

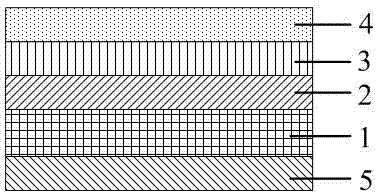

Image

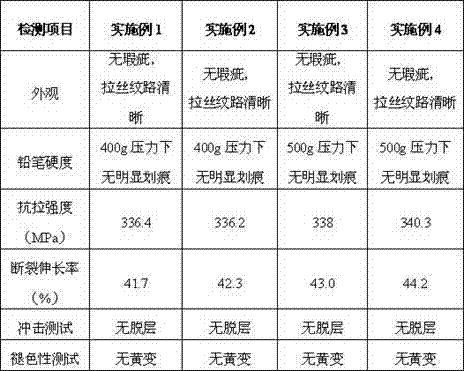

Examples

Embodiment 1

[0027] The base material is hot-dip galvanized steel plate with a thickness of 0.4mm;

[0028] The front side of the base material is processed by the metal surface wire drawing machine. The metal surface wire drawing machine is equipped with two sets of differential rollers rotating in the same direction. The upper roller is a fast-rotating grinding roller, and the lower roller is a slow-speed transfer rubber Roller, the substrate is conveyed through two sets of rollers, and the fine straight grain drawing is processed on the front of the substrate by mechanical friction;

[0029] Degrease and clean the substrate treated by the wire drawing process to remove surface oil stains and dry it at 50°C;

[0030] After degreasing and cleaning, the surface passivation treatment is carried out by spraying. The passivation agent used in the passivation treatment is Aldoine 5200, a chromium-free passivation agent from Henkel, to form a colorless paint-based passivation film on the front ...

Embodiment 2

[0035] The base material is hot-dip galvanized steel plate with a thickness of 0.4mm;

[0036] The front side of the base material is processed by the metal surface wire drawing machine. The metal surface wire drawing machine is equipped with two sets of differential rollers rotating in the same direction. The upper roller is a fast-rotating grinding roller, and the lower roller is a slow-speed transfer rubber Roller, the substrate is conveyed through two sets of rollers, and the fine straight grain drawing is processed on the front of the substrate by mechanical friction;

[0037] Degrease and clean the substrate treated by the wire drawing process to remove surface oil stains and dry at 60°C;

[0038] After degreasing and cleaning, the surface passivation treatment is carried out by spraying. The passivation agent used in the passivation treatment is Aldoine 5200, a chromium-free passivation agent from Henkel, to form a colorless paint-based passivation film on the front and...

Embodiment 3

[0043] The base material is hot-dip galvanized steel plate with a thickness of 0.5mm;

[0044] The front side of the base material is processed by the metal surface wire drawing machine. The metal surface wire drawing machine is equipped with two sets of differential rollers rotating in the same direction. The upper roller is a fast-rotating grinding roller, and the lower roller is a slow-speed transfer rubber Roller, the substrate is conveyed through two sets of rollers, and the fine straight grain drawing is processed on the front of the substrate by mechanical friction;

[0045] Degrease and clean the substrate treated by the wire drawing process, remove surface oil stains, and dry at 50°C;

[0046] After degreasing and cleaning, the surface passivation treatment is carried out by spraying. The passivation agent used in the passivation treatment is Aldoine 5200, a chromium-free passivation agent from Henkel, to form a colorless paint-based passivation film on the front and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com