Post-rolling cooling control method using plurality of cooling systems

A cooling control and cooling system technology, applied in metal rolling, temperature control, metal rolling, etc., can solve problems such as insufficient cooling capacity, and achieve the effect of satisfying cooling process requirements and good application effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

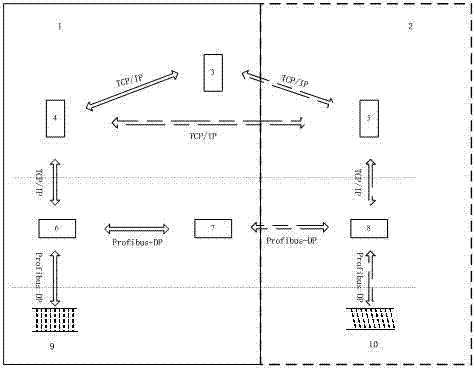

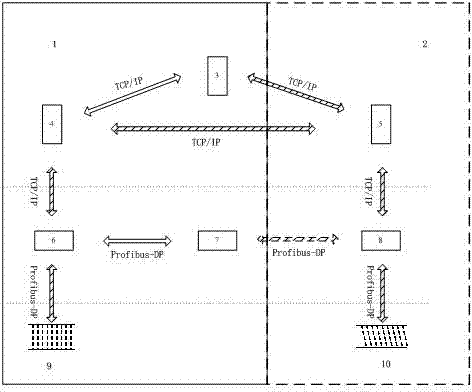

[0020] The post-rolling cooling control system for medium and thick plates with multiple systems coexisting and flexible switching in the present invention transforms the original laminar flow cooling equipment and adds a set of ultra-fast cooling control system, so that it can be organically combined with the original ACC system to form a new complete set The post-rolling cooling control system is characterized by establishing a communication system, adding a second level of post-rolling cooling process control system and a new level of ultra-fast cooling basic automation control system:

[0021] 1. Establishment of cooling control system for plate after rolling

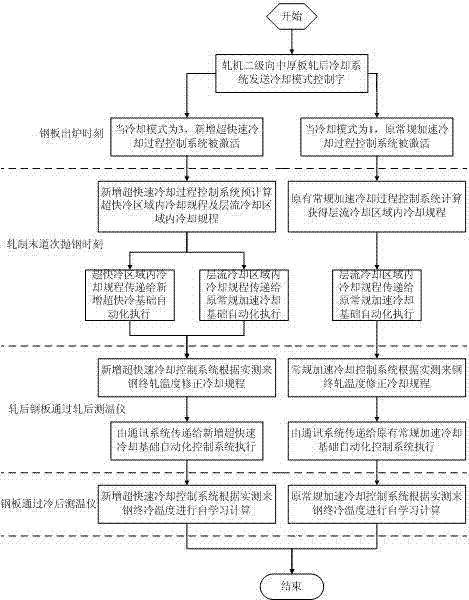

[0022] The control logic of the post-rolling cooling system is as follows: figure 1 shown. The basic automation system is L1-level control, mainly for equipment, control components and logic control. Process control is L2 level control, which is mainly used for process model calculation. The L2 level calculation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com