Catalytic combustion catalyst and preparing method thereof

A catalytic combustion and catalyst technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc. Inactivation of organic waste gas adaptability and other issues, to achieve the effect of strong processing adaptability, easy operation and industrial production, preparation method and equipment are simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

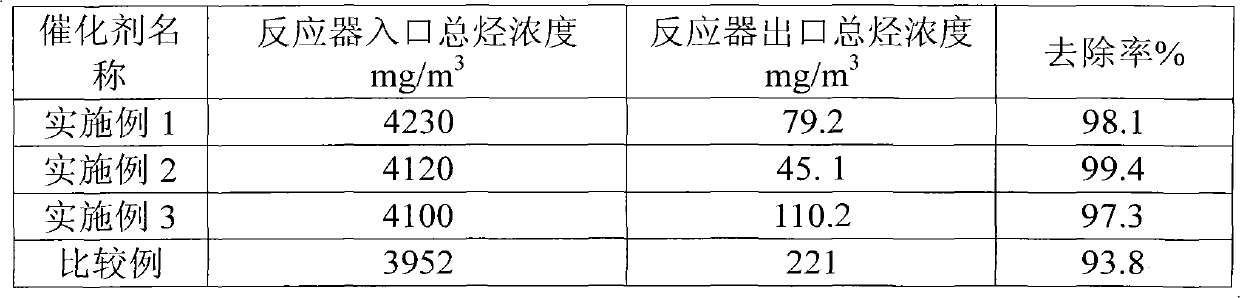

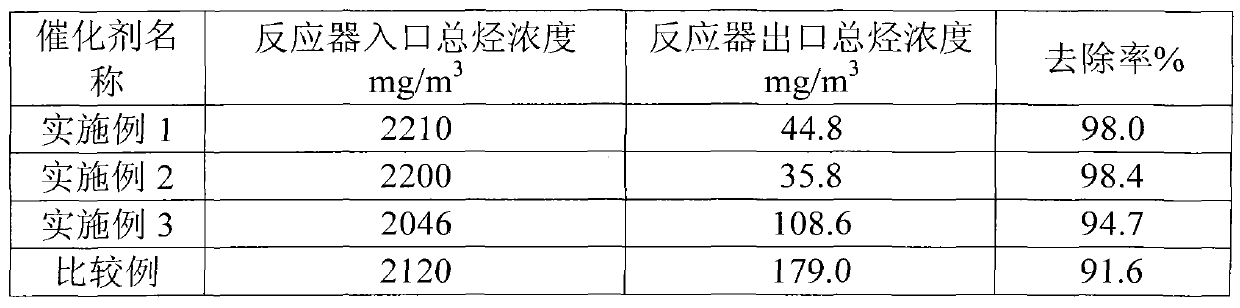

Examples

Embodiment 1

[0020] Soak the honeycomb ceramic carrier with a size of 100mm×100mm×50mm in dilute hydrochloric acid with a mass concentration of 1% for 2 hours, wash the carrier and the dilute acid liquid under microwave for 2 hours, take it out and blow dry, and place it in a refrigerator at 100°C. After 6 hours in an oven, the obtained carrier was fired for 5 hours to obtain a clean and dry honeycomb ceramic carrier for use.

[0021] Use distilled water as a solvent to prepare a cerium nitrate solution with a concentration of 0.3 mol / L, add an appropriate amount of citric acid to make the pH of the solution 4, stir at 70°C for 6 hours, and use ammonia water to adjust the pH value to 7.9 to produce stable cerium Sol spare.

[0022] Select the average particle size of 10 ~ 200nm, SiO 2 Ammonia cationic silica sol with a content of 25%, put the pretreated carrier into the silica sol for 30 minutes, take it out, blow out the slurry in the channel with compressed air, dry at 160°C for 6 hours...

Embodiment 2

[0025] Soak the honeycomb ceramic carrier with a size of 100mm×100mm×50mm in dilute hydrochloric acid with a mass concentration of 2% for 2 hours, wash the carrier and the dilute acid liquid under microwave for 2 hours, take it out, blow dry, and place it in a 110°C refrigerator. After 4 hours in an oven, the obtained carrier was fired for 5 hours to obtain a clean and dry honeycomb ceramic carrier for use.

[0026] Use distilled water as a solvent to prepare a cerium nitrate solution with a concentration of 0.15mol / L, add an appropriate amount of citric acid to make the pH of the solution 5, stir at 90°C for 4 hours, and use ammonia water to adjust the pH value to 8.5 to form a stable sol for later use .

[0027] Select the average particle size of 10 ~ 200nm, SiO 2 For decationized silica sol with a content of 30%, put the pretreated carrier into the silica sol for 15 minutes and take it out, blow out the slurry in the pores with compressed air, dry at 110°C for 4 hours, an...

Embodiment 3

[0030] Soak the honeycomb ceramic carrier with a size of 100mm×100mm×50mm in dilute hydrochloric acid with a mass concentration of 1% for 6 hours, wash the carrier and the dilute acid liquid under microwave for 4 hours, take it out and dry it, and place it in a 70°C refrigerator. After 6 hours in an oven, the obtained carrier was fired for 5 hours to obtain a clean and dry honeycomb ceramic carrier for use.

[0031] Use distilled water as a solvent to prepare a cerium nitrate solution with a concentration of 0.1mol / L, and add an appropriate amount of citric acid to make the pH of the solution 5, stir at 110°C for 12 hours, use ammonia water to adjust the pH value to 7.5, and form a stable sol for later use .

[0032] Select the average particle size of 10 ~ 200nm, SiO 2 For sodium cationic silica sol with a content of 20%, put the pretreated carrier into the silica sol for 40 minutes and take it out, blow out the slurry in the pores with compressed air, dry at 70°C for 4 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com