Preparation method for sausage

A production method and sausage technology, applied in the directions of food preparation, application, food science, etc., can solve the problem of difficult control of fire control sausage, and achieve the effect of eliminating potential safety hazards, good appearance, and ensuring food safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

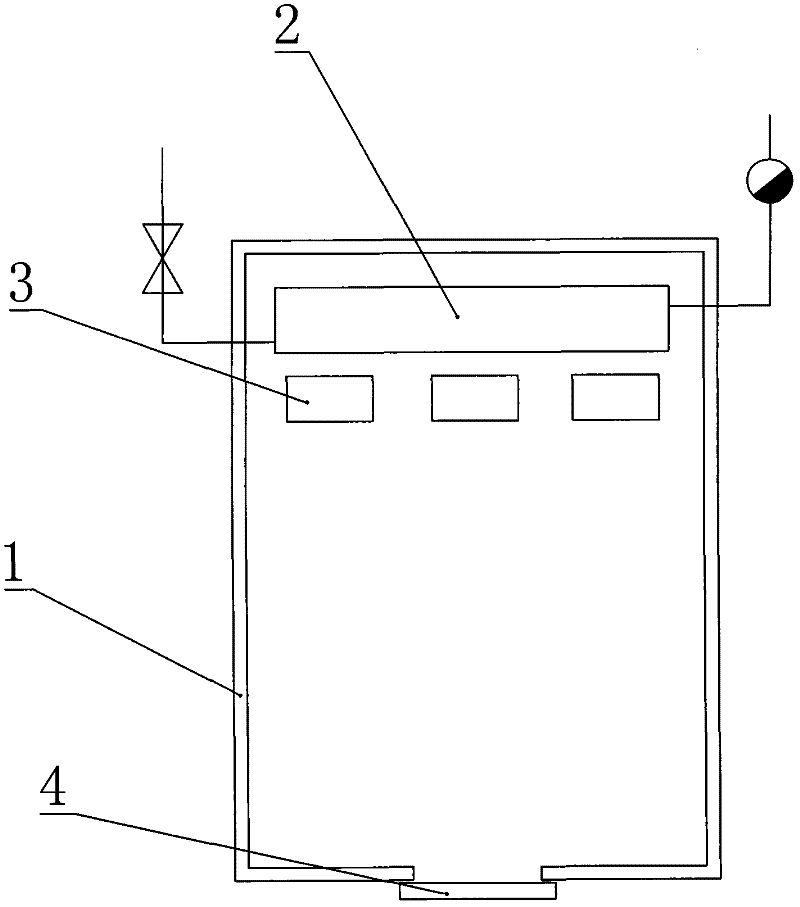

Image

Examples

Embodiment 1

[0014] Pork processing: Use a φ8mm orifice plate to grind the lean pork with a meat temperature of ≤10°C, and control the twisting temperature: the temperature of the ground pork is ≤12°C. Carry out dicing to fatty pork, wash with the warm water of 50 ℃ after cutting into the granule of 4mm.

[0015] With salt water: ginger juice, white wine, and nitrous acid are first stirred with water, and then salt, sugar, and monosodium glutamate are added and fully stirred until they are dissolved.

[0016] Intestine stuffing preparation: Stir the lean meat with the salt solution first, and finally add the ridge fat grains and stir until evenly mixed.

[0017] Filling: Put the sausage casing on the sausage enema machine for routine sausage enema. After the sausage enema is finished, use a buckle rope to make each section 20cm long, then use triangular aluminum to string it, then put it in the pool to clean off the floating meat of the intestine body, and finally put it on the baking rack...

Embodiment 2

[0026] Making the Sausage Belly:

[0027] Material selection (the ratio of the components is the mass percentage): pork: 82%, pork loin fat: 4%, salt: 3.2%, white sugar: 8.7%, monosodium glutamate: 0.346%, white wine: 0.337%, spiced spices: 0.015%, ginger : 1.4%, nitrous: 0.002%,

[0028] Except that the lean pork with a meat temperature of ≤10° C. is ground through an orifice plate with a diameter of φ8 mm, the other processes are consistent with the embodiments.

[0029] The sausage belly of the above components has been tested, and the content of benzopyrene is 0 μg / kg, there is no impurity content, the acid value is 3.0 mg / kg, and the peroxide value is 0.3 g / 100g. The national standard for the above substances is that the content of benzopyrene is ≤5 μg / kg. Acid value ≤ 4.0mg / kg, peroxide value ≤ 0.5g / 100g From the perspective of content comparison, the food quality of Soviet-style sausages produced by this process is far superior to international standards. From the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com