Process for co-producing synthesis gas and power

一种合成气体、共同生产的技术,应用在气化工艺、氢/合成气生产、气体处理等方向,能够解决缺少大规模设备相集成等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

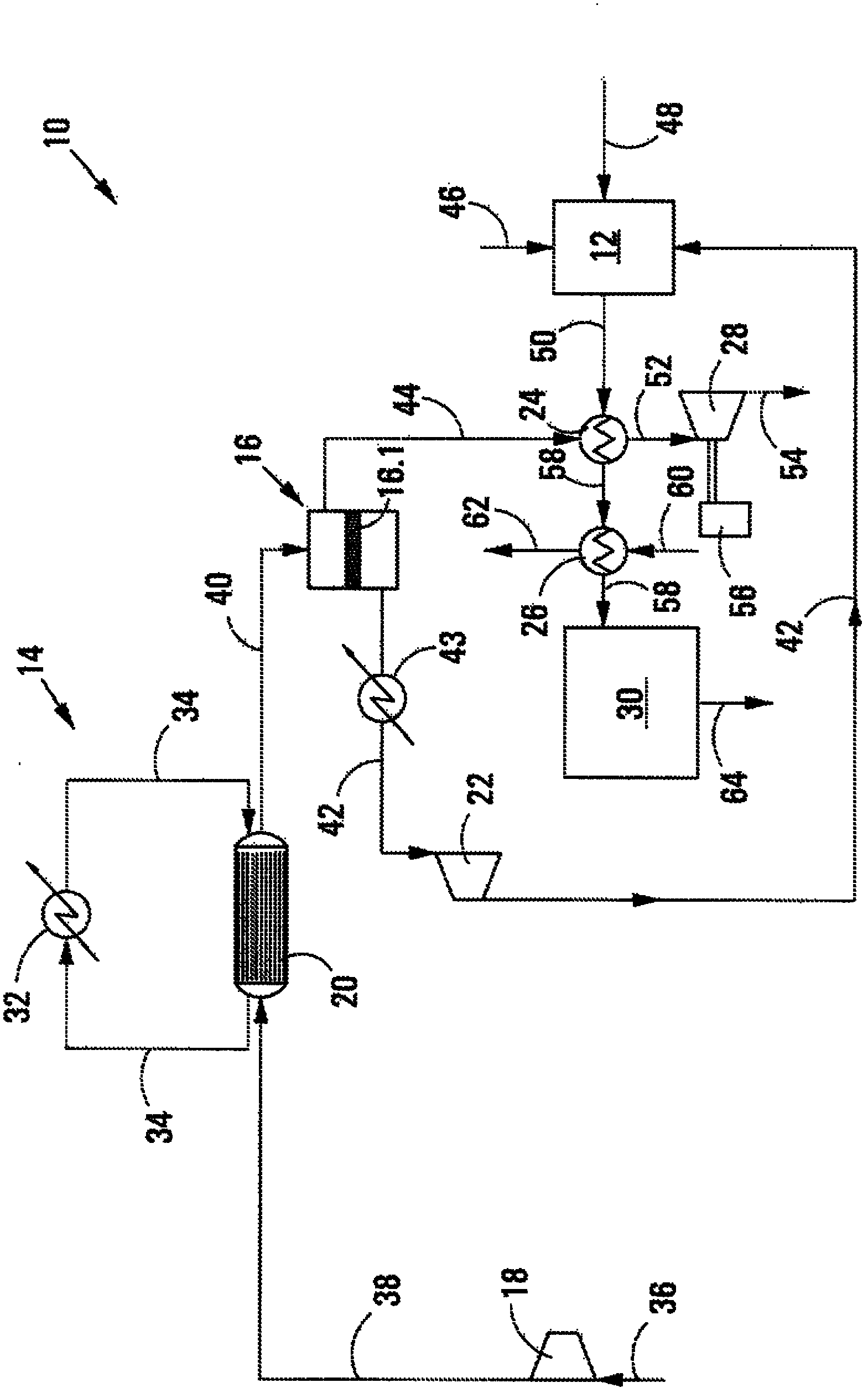

[0048] with reference to the attached figure 1 , reference numeral 10 generally designates a process according to the invention for the co-production of synthesis gas and energy. Process 10 generally includes a synthesis gas generation stage 12, a nuclear reaction stage 14, and an air separation stage 16 including at least one ion transport membrane 16.1.

[0049] Process 10 also includes air compressor 18 , air heater 20 , oxygen compressor 22 , synthesis gas cooler 24 , synthesis gas waste heat boiler 26 , gas turboexpander 28 , and hydrocarbon synthesis stage 30 .

[0050] The nuclear reaction stage 14 utilizes a high temperature gas cooled nuclear reactor 32 with helium as a gas coolant circulating through the high temperature gas cooled nuclear reactor 32 . The nuclear reaction stage 14 may be a typical or conventional high temperature gas cooled nuclear reaction stage in which helium is operated in a closed helium cycle 34 at a pressure of 70 bar(g). In the figure, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com