Alternating current (AC) ice melting system for traction network of electrified railway

A technology for electrified railways and traction nets, applied in the installation of electrical components, cables, and overhead installations, can solve problems such as low power utilization, high cost of rectification devices, and low safety and reliability, and achieve high energy utilization and equipment High reliability, high safety and reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

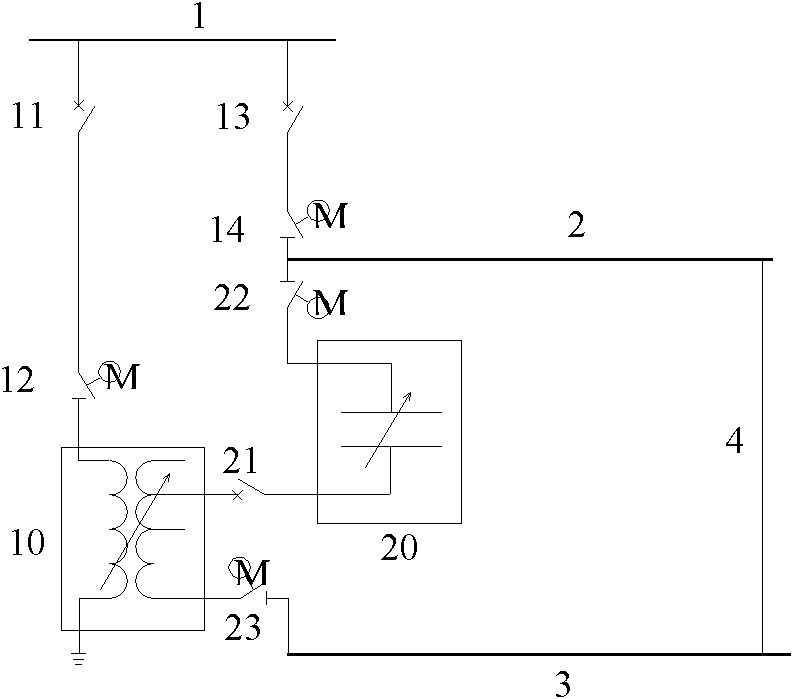

[0024] Such as figure 1 shown. The step-down transformer 10 and capacitive electrical equipment 20 are installed in or near the traction substation. The high voltage side of the step-down transformer 10 is connected to the 27.5kV bus 1 of the traction substation through the first isolating switch 12 and the first circuit breaker 11 . The low-voltage side of the step-down transformer 10 is first connected to the capacitive electrical equipment 20, and then connected to the catenary 2, other conductors 3 of the traction network and the connecting conductor 4 to form an ice-melting circuit.

[0025] During normal operation without icing on the catenary 2, the first circuit breaker 11, the first isolating switch 12, the third circuit breaker 21, the third isolating switch 22, and the fourth isolating switch 23 are all in the off state. When icing occurs on the catenary 2 and ice-melting work needs to be carried out, the operation steps of this embodiment are as follows:

[0026]...

Embodiment 2

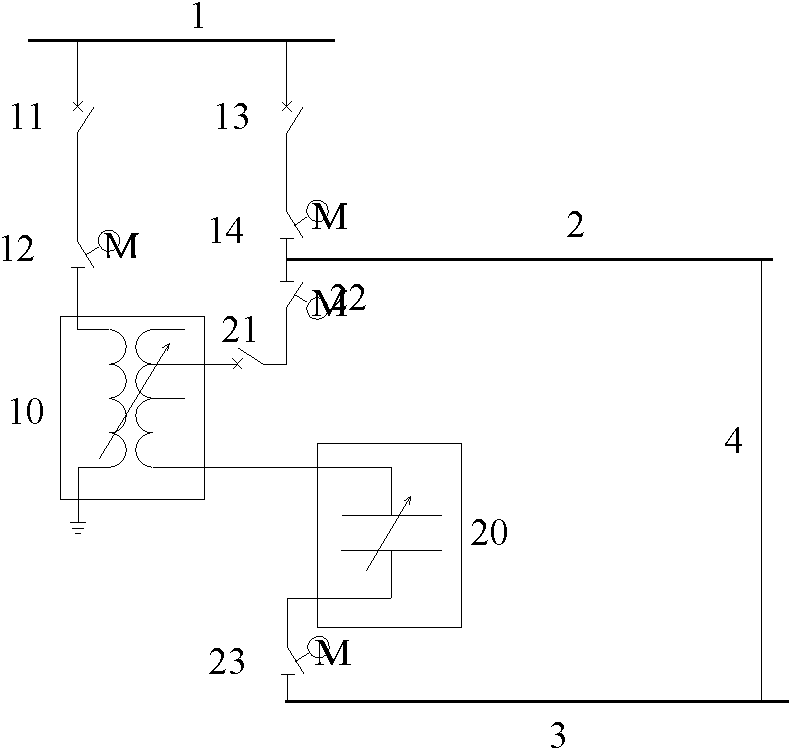

[0035] Such as figure 2 shown. The step-down transformer 10 and the capacitive electrical equipment 20 are installed in or near the traction substation. The high voltage side of the step-down transformer 10 is connected to the 27.5kV bus 1 of the traction substation through an isolating switch 12 and a circuit breaker 11 . The low-voltage side of the step-down transformer 10 is first connected to the catenary 2, the connecting conductor 4 and other conductors 3 of the traction network, and then connected to the capacitive electrical equipment 20 to form an ice-melting circuit.

[0036]During normal operation without icing on the catenary 2, the first circuit breaker 11, the first isolating switch 12, the third circuit breaker 21, the third isolating switch 22, and the fourth isolating switch 23 are all in the off state. When icing occurs on the catenary 2 and ice-melting work needs to be carried out, the operation steps of this embodiment are as follows:

[0037] Open the s...

Embodiment 3

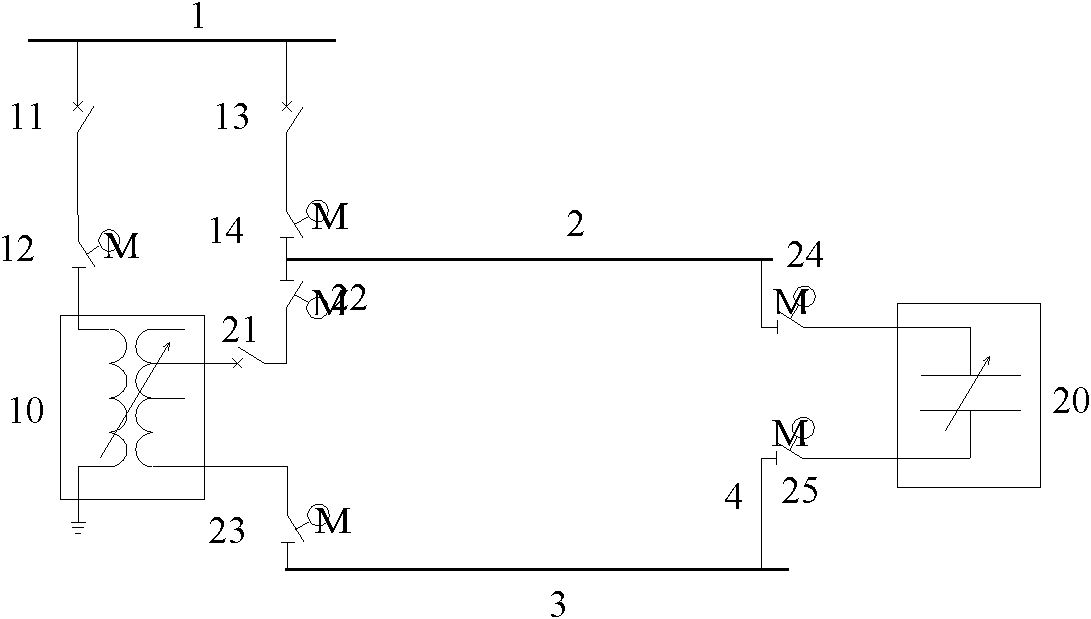

[0046] Such as image 3 shown. The step-down transformer 10 is installed in or near the traction substation, and the capacitive electrical equipment 20 is installed near the split phase at the end of the power supply arm (or in or near the divisional substation). The low-voltage side of the step-down transformer 10 is first connected with the catenary 2, and then connected with the other conductors 3 of the traction network through the capacitive electrical equipment 20 and the connecting conductor 4 to form an ice-melting circuit.

[0047] During normal operation without ice coating on the catenary 2, the first circuit breaker 11, the first isolating switch 12, the third circuit breaker 21, the third isolating switch 22, the fourth isolating switch 23, the fifth isolating switch 24, the first 6 The isolation switches 25 are all in the disconnected state.

[0048] When icing occurs on the catenary 2 and ice-melting work needs to be carried out, the operation steps of this em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com