Preparation method of cobaltosic oxide nano cage and cobaltosic oxide nano cage prepared by adopting same

A technology of cobalt trioxide nanometer and cobalt cyanate cobalt cyanate, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc. It can solve the problems of high equipment requirements, complicated process, difficult large-scale preparation, etc., and achieve the goal of manufacturing The process is simple, the equipment requirements are not high, and the effect of large-scale production is realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

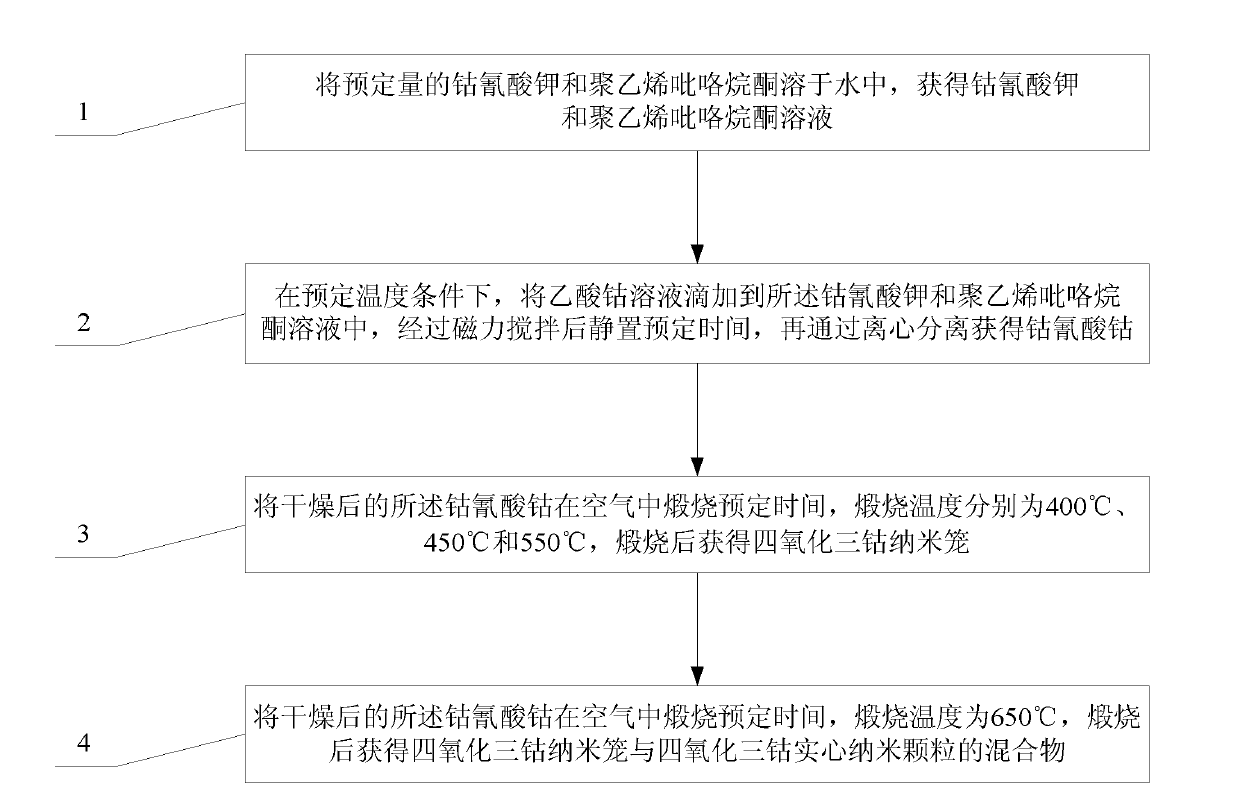

[0022] This specific embodiment provides a kind of preparation method of cobalt tetraoxide nanocage and the cobalt tetraoxide nanocage prepared by this method, such as figure 1 Shown, corresponding preparation method comprises:

[0023] Step 1, dissolving a predetermined amount of potassium cobaltcyanate and polyvinylpyrrolidone in water to obtain a solution of potassium cobaltcyanate and polyvinylpyrrolidone;

[0024] Step 2, under predetermined temperature conditions, add the cobalt acetate solution dropwise into the potassium cobalt cyanate and polyvinylpyrrolidone solution, leave it for a predetermined time after magnetic stirring, and then obtain cobalt cobalt cyanate by centrifugation;

[0025] Step 3, calcining the dried cobalt cobalt cyanate in the air for a predetermined time, the calcining temperatures are 400°C, 450°C and 550°C respectively, and obtaining tricobalt tetroxide nanocages after calcining;

[0026] Step 4, calcining the dried cobalt cyanate in the air f...

Embodiment 1

[0028] Embodiment 1. prepares homogeneous cobalt tetraoxide nanocage

[0029] At room temperature, 10 mL containing 18 mg cobalt acetate (Co(CH 3 COO) 2 ) solution was added dropwise to 10mL containing 17mg K 3 [Co(CN) 6 ] and 0.3 g of PVP, after magnetic stirring, stand still for 24 hours, and centrifuge to obtain the precursor cobalt cobalt cyanate; place the obtained cobalt cobalt cyanate powder in a muffle furnace at 400°C for calcination in air for 1 hour. The particle diameter is about 60 nm or so cobalt tetraoxide nanocage.

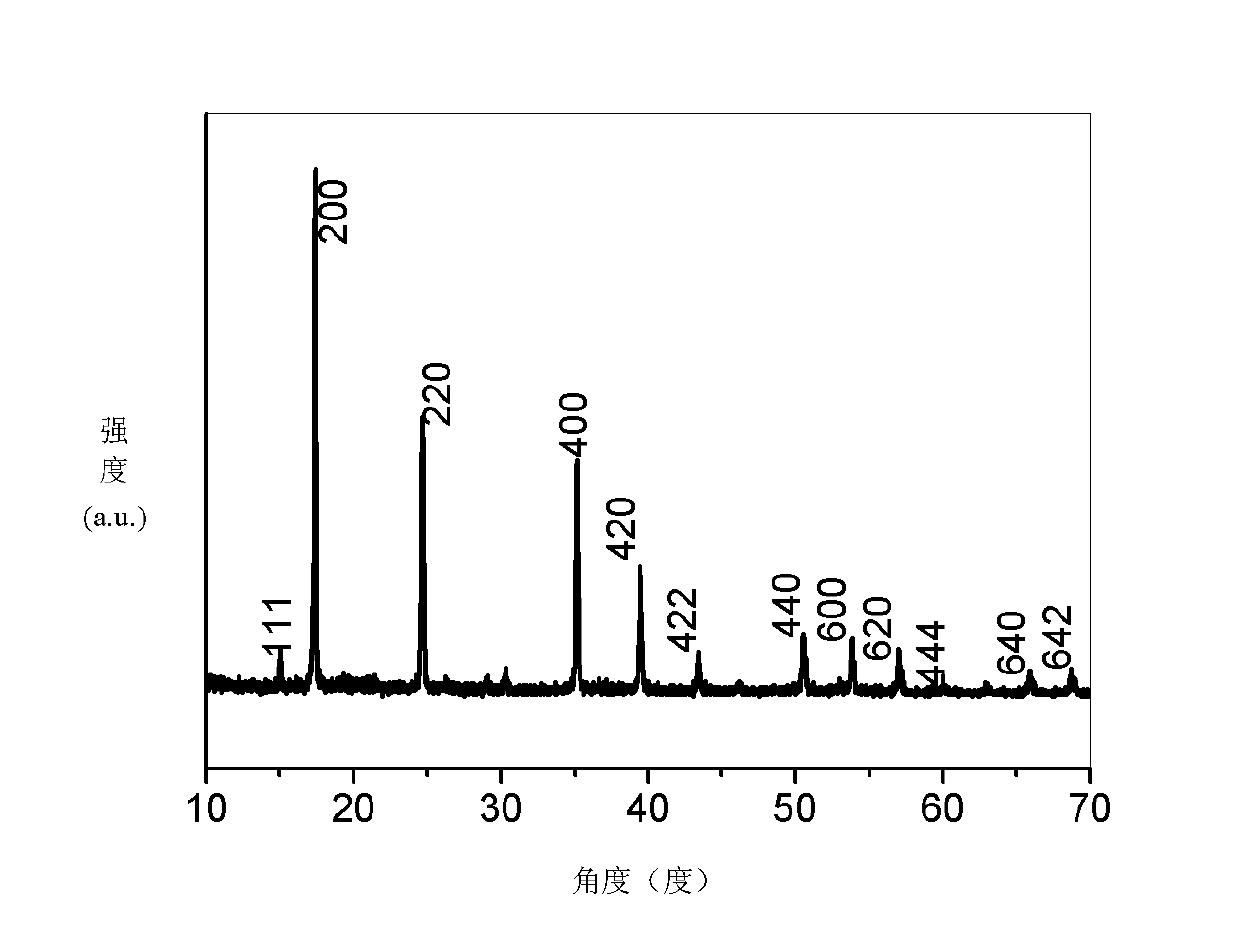

[0030] Such as figure 2 Shown, the X-ray diffraction of the precursor in this embodiment Figure, all diffraction peak positions correspond to cobalt cyanate (111), (200), (220), (400), (420), (422), (440), (600), (620), (444), (640), (642) surface, show that the product is cobalt cobalt cyanate. Scanning and transmission electron microscopy images of the product ( image 3 ) It can be seen that the shape of the precursor is a cube with tr...

Embodiment 2

[0031] Embodiment 2. The influence of calcination temperature on product

[0032] The precursor was calcined at 450°C, 550°C, and 650°C for one hour to obtain a black product. Figure 8 Figures a, b, and c in the figure correspond to the scanning electron microscope pictures of the product obtained at 450°C, 550°C, and 650°C, respectively. It can be seen that with the increase of temperature, the morphology of the product has a certain change. When the temperature is 450°C or 550°C, the particle is a hollow nanocage with a particle diameter of about 40-50nm. When the temperature was 650 °C, part of the product turned into solid nanoparticles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com