Laser initiation flyer type initiating explosive-free detonator

A non-priming, flyer-type technology, which is applied to weapon accessories, fuzes, offensive equipment, etc., can solve the problems of large volume of detonating devices, high laser energy, and difficulty in refugee use, and achieves excellent electromagnetic resistance, high output power, and The effect of improving energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

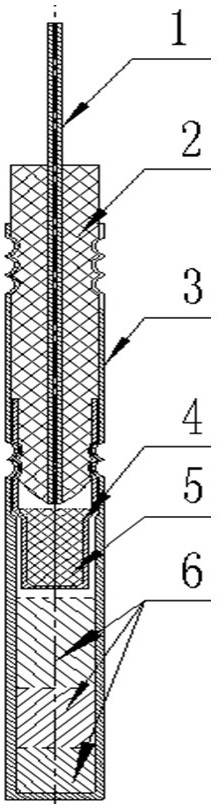

[0026] see figure 1 . In the figure, the core diameter of fiber 1 is 400um, the fiber cladding is 430um, the thickness of the plastic layer is 730um, the numerical aperture (NA) is 0.37, and one end has an SMA905 fiber interface for the connection between the fiber and the laser. The outer surface of the rubber plug 2 is closely matched with the inner surface of the detonator case 3. The outer diameter of the rubber plug is 5.8 mm, the middle aperture is 3.0 mm, the outer diameter of the detonator case is 7.0 mm, and the inner diameter is 6.2 mm. The outer surface of the lower part of the rubber plug 2 is in interference fit with the inner wall surface of the upper part of the variable section inner cap 4. The total height of the inner cap is 12 mm, the outer diameter of the upper part is 6.2 mm, the inner diameter is 5.4 mm, the height is 7 mm, and the outer diameter of the lower part is 5.8 mm. Inner diameter 5.0mm, height 5mm. The fourth charge 5 in the cavity of the vari...

Embodiment 2

[0031] Figure 4 It is a schematic diagram of the structure of the laser-initiated equal-section flyer-type non-primer detonator. In the figure, the total height of the equal-section inner cap 7 is 15 mm, the outer diameter is 6.2 mm, and the inner diameter is 5.4 mm. The 4th medicine 8 of packing in equal section inner cap 7 lumens is RDX / KClO 3 , where KClO 3 The mass ratio to RDX is 1, and the packing density is 1.6g / cm 3 , charge amount 0.4g, filling height 8mm. There are 3 bayonets on the superimposed part of the detonator, and the diameter of the bayonets is 4.8mm.

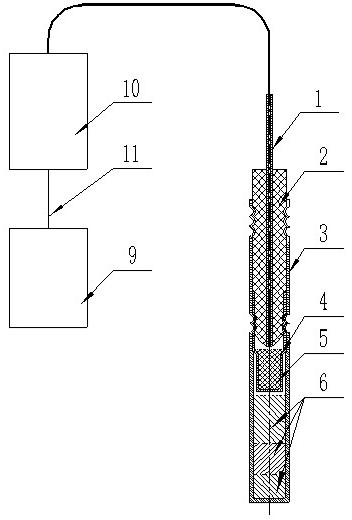

[0032] according to figure 2 connection shown Figure 4 The flying chip detonator with equal cross-section of the laser is connected to the power supply, and the laser is output, and the detonator is detonated immediately.

Embodiment 3

[0034] Figure 5 It is a schematic diagram of the detonation system using laser beam splitting to realize multiple simultaneous detonation of flying chip detonators. In the figure, the power supply 9 is connected to the laser 10 through the connecting line 11, the laser output from the laser 10 passes through the optical fiber 1 to the optical fiber beam splitter 12, and then divides a bundle of optical fibers into 4 paths through the optical fiber beam splitter 12, and the separated 4 The optical fibers are respectively connected with a laser detonated flyer detonator. The power supply 9 is switched on, and the flyer detonators 13, 14, 15, 16 of detonating laser detonation are respectively detonated by four optical fibers of the optical fiber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Core diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com