Novel nanometer titanium dioxide self-cleaning fluorine-carbon aluminum single sheet as well as low-temperature preparation method and application thereof

A nano-titanium dioxide, fluorocarbon aluminum veneer technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, coating, etc., can solve the problems of poor stain resistance, achieve uniform distribution, improve self-cleaning effect, and grain distribution uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Low-temperature preparation of titanium dioxide film on the surface of fluorocarbon aluminum veneer

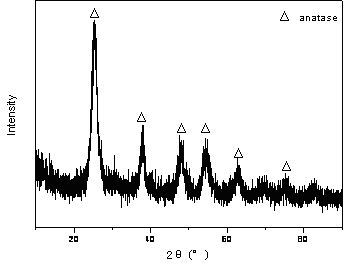

[0028] Measure 5ml of tetrabutyl titanate, add it to 10ml of absolute ethanol, then add 2ml of glacial acetic acid dropwise thereto, and mix thoroughly at room temperature to obtain solution A. Take 10ml of absolute ethanol, 30ml of 0.2mol / l hydrochloric acid solution, 1ml of 1% acetic acid solution and 1ml of KH570 and mix thoroughly to obtain solution B. Slowly add solution B to solution A, mix well and heat to reflux at 80°C for 10h to obtain nano-TiO 2 Sol, aged for 1-3d for later use. Nano TiO 2 The sol is sprayed on the surface of the pretreated fluorocarbon aluminum veneer to form a layer of nano-TiO 2Heat treatment at 200°C for 3 hours after the thin film to obtain nano-titanium dioxide self-cleaning fluorocarbon aluminum veneer, such as figure 1 , figure 2 shown.

Embodiment 2

[0029] Example 2: Low-temperature preparation of titanium dioxide / silicon dioxide composite film on the surface of fluorocarbon aluminum veneer

[0030] Measure 5ml of tetrabutyl titanate, add it to 10ml of absolute ethanol, then add 2ml of glacial acetic acid dropwise thereto, and mix thoroughly at room temperature to obtain solution A. Take 10ml of absolute ethanol, 30ml of 0.2mol / l hydrochloric acid solution, 1ml of 1% acetic acid solution and 1ml of KH570 and mix thoroughly to obtain solution B. Slowly add solution B to solution A, mix well and heat to reflux at 80°C for 10 hours to obtain nano-TiO2 sol; measure 1ml of tetraethyl orthosilicate and add 1ml of absolute ethanol to mix thoroughly to obtain solution C, drop into solution C Add a mixture of 1ml 1% acetic acid solution and 2ml absolute ethanol, mix well at room temperature to get SiO 2 sol; the freshly prepared SiO 2 Sol and TiO 2 Sol mixing, aging for 1-3d to produce TiO 2 / SiO 2 Composite sol. TiO 2 / S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com