Method for preparing micro nano-crystalline cellulose with mechanical force chemical method

A micro-nano cellulose and mechanochemical technology, applied in the field of materials, can solve the problems of not being in a lively chemically active state, combining at the same time, low chemical reaction efficiency and rate, etc., to achieve low cost, reduce energy consumption, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

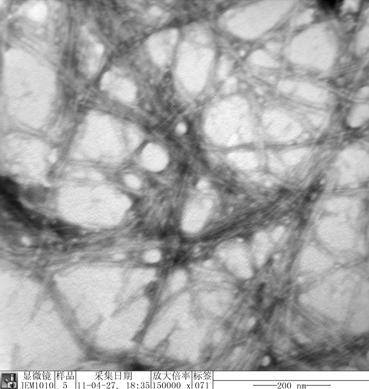

[0027] Weigh 1g of chemical pulp (sulphate wood pulp, purchased from Nanping Paper Mill), add to 5g of H2O with a mass fraction of 85% 3 PO 4 solution, put the above materials into a vibrating ball mill, and grind continuously for 1 hour to obtain transparent cellulose / H 3 PO 4 Mixture. Add an appropriate amount of water to precipitate the cellulose and obtain a white jelly. Add water to the white jelly and centrifuge, remove the lower layer of cellulose jelly to obtain micro-nano cellulose with a yield of 97%. It can be seen from the transmission electron micrograph observation that the micronano cellulose prepared by this method has a diameter of 20-30nm, a length of 300-700nm, and a network structure. like figure 1 shown.

[0028] Horizontal grinder or colloid mill

Embodiment 2

[0030] Take by weighing 20g microcrystalline cellulose, add to 400g massfraction 1% H 2 SO 4 / HCl mixed solution, stirred and milled for 20min to obtain cellulose / H 2 SO 4 / HCl mixture. Add an appropriate amount of water and centrifuge to separate layers (centrifugal speed is 6000 rpm, 10 minutes each time), and after removing the upper layer solution, the lower layer of cellulose jelly is micro-nano cellulose, with a yield of 94%.

Embodiment 3

[0032] Weigh 5 g of absorbent cotton, add it to 100 g of NaOH solution with a mass fraction of 50%, and vibrate and grind for 30 min to obtain a cellulose / NaOH mixture. Add an appropriate amount of water and centrifuge to separate layers (centrifugal speed is 10,000 rpm, 6 minutes each time). After removing the upper layer solution, the lower layer of cellulose jelly is micro-nano cellulose, and the yield is 95%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com