Functional fiber, manufacturing method and fabric formed via weaving functional fiber

A technology of functional fibers and functional substances, applied in fabrics, fiber treatment, textiles, etc., can solve the problems of reduced fiber spinnability and low utilization of functional substances, and achieve large porosity, high functional activity, and strengthened Diffusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

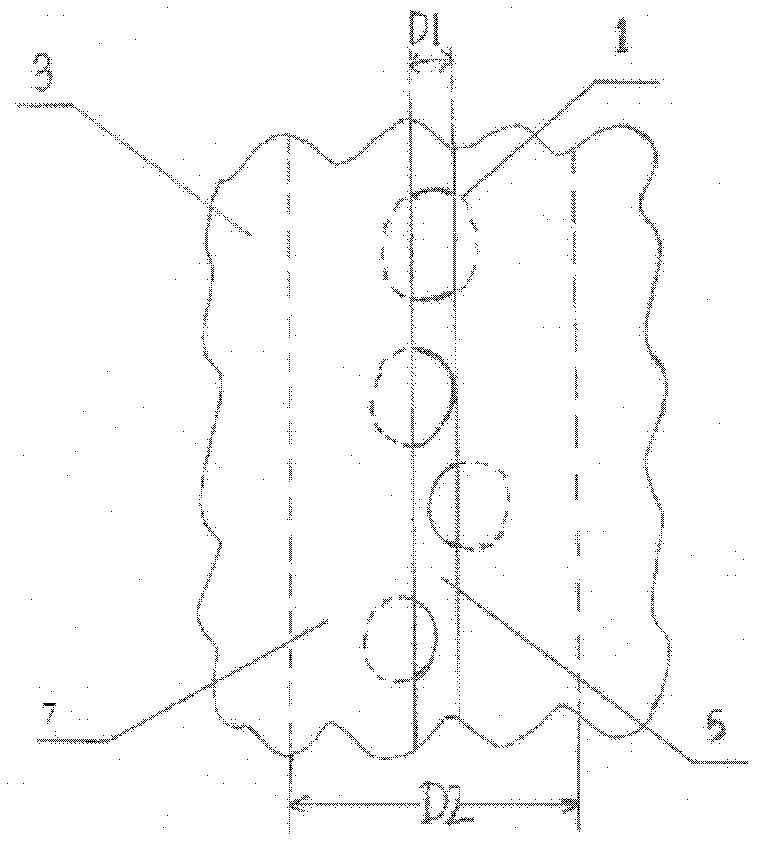

[0043] The dried polyester chips are heated and extruded to be melted with a screw, the temperature of the screw is 280° C., and the rotation speed is 100 rpm. The melt is sent to each spinning position of the spinning box, and is accurately metered and filtered by the metering pump, and then sprayed out from the spinneret. The diameter of the spinneret holes was 100 μm. After the thin stream of melt is sprayed out, it is cooled and solidified into filaments by the cooling air flow. There is one hole in the cross-section of the fiber, and the opening size of the hole on the fiber surface is 40-60 μm, that is, the feeding gap of the special-shaped hole of the spinneret is set at 40-60 μm. The silver ion antibacterial agent with an average particle size of 20-30 μm is used as a functional substance, and the spinning machine oil with a content of 10 wt % of the functional substance is prepared after being dispersed by ultrasonic vibration. After the solidified filaments are wet...

Embodiment 2

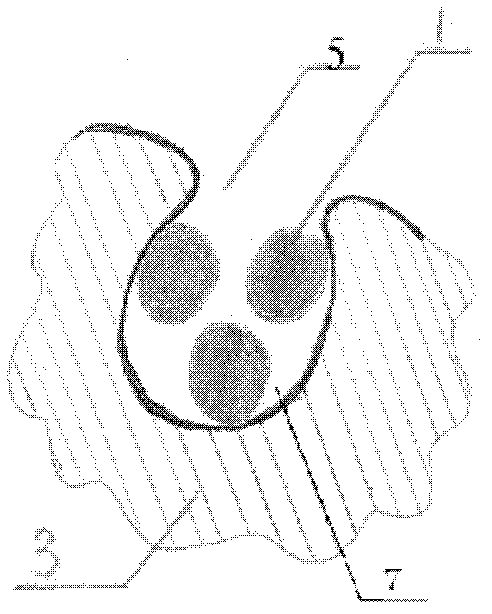

[0049] The dried polyester chips are heated and extruded to be melted with a screw, the temperature of the screw is 280° C., and the rotation speed is 100 rpm. The melt is sent to each spinning position of the spinning box, and is accurately metered and filtered by the metering pump, and then sprayed out from the spinneret. The diameter of the spinneret holes was 100 μm. After the thin stream of melt is sprayed out, it is cooled and solidified into filaments by the cooling air flow. There are 3 holes in the cross-section of the fiber, and the opening size of the holes on the fiber surface is 20-30 μm, that is, the feeding gap of the special-shaped hole of the spinneret is set at 20-30 μm. Use TiO with an average particle size of 10-15 μm 2 Anti-virus and deodorizing functional substances are dispersed by ultrasonic vibration to prepare spinning machine oil with a content of 10wt% functional substances. After the solidified thread passes through an oil bath, the fiber stays ...

Embodiment 3

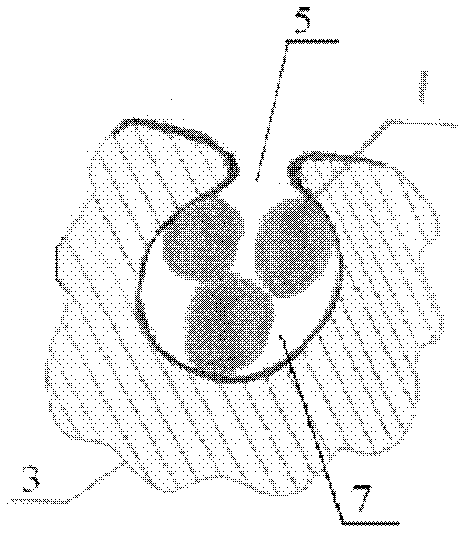

[0055] The dried polyester chips are heated and extruded to be melted with a screw, the temperature of the screw is 280° C., and the rotation speed is 100 rpm. The melt is sent to each spinning position of the spinning box, and is accurately metered and filtered by the metering pump, and then sprayed out from the spinneret. The diameter of the spinneret holes was 150 μm. After the thin stream of melt is sprayed out, it is cooled and solidified into filaments by the cooling air flow. There are 2 holes in the cross-section of the fiber, and the opening size of the holes on the fiber surface is 30-50 μm, that is, the feeding gap of the special-shaped hole of the spinneret is set at 30-50 μm. The tourmaline negative ion powder with an average particle size of 15-20 μm is used as a functional substance, and the spinning machine oil with a content of 12 wt % of the functional substance is prepared after surface modification and dispersion. When spinning filaments, the filaments ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com