Suede-structured ZnO film prepared by alternative growth technology and application thereof

A technology of alternate growth and thin film, applied in the direction of gaseous chemical plating, coating, electrical components, etc., can solve the problems of affecting the transmittance of the thin film, reducing the texture, and reducing the light scattering ability of the thin film, so as to improve the photoelectric conversion efficiency, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

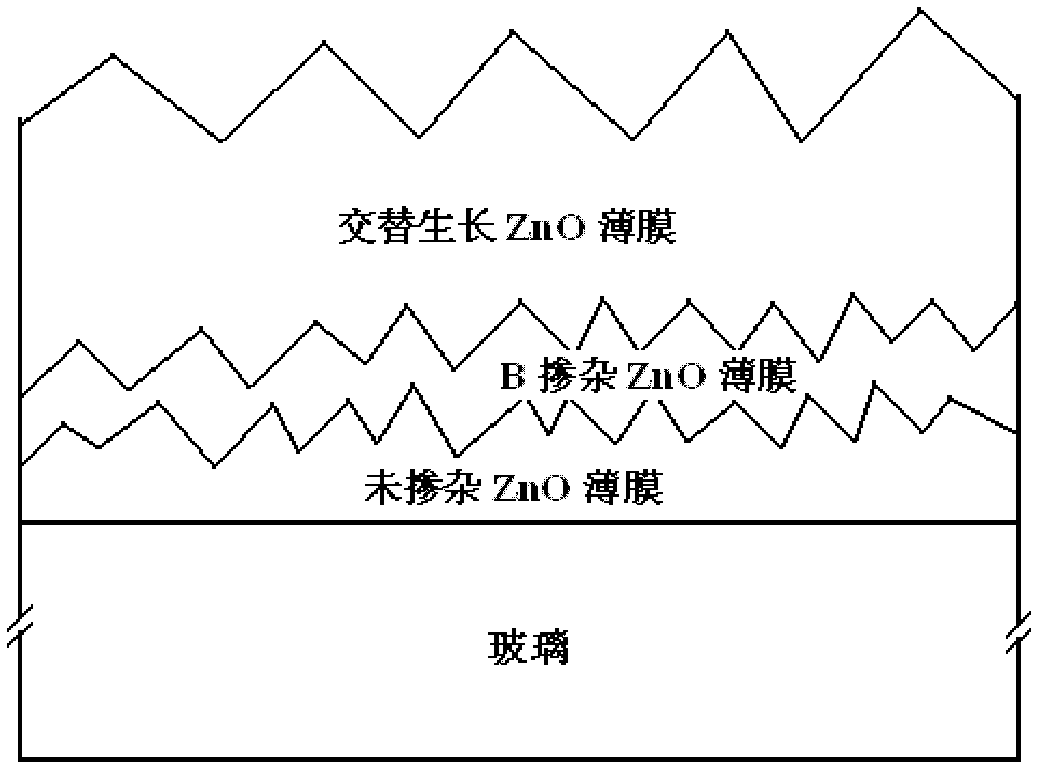

[0024] An alternate growth technique to prepare textured ZnO thin films, using diethyl zinc and water with a purity of 99.995% as source materials, and borane B 2 h 6 For the doping gas, dilute the doping gas borane B with hydrogen 2 h 6 , doping gas borane B 2 h 6 The volume percent concentration in the mixed gas is 1.0%, and metal organic chemical vapor deposition (MOCVD) is used to alternately grow the textured structure ZnO-TCO film on the glass substrate, the steps are as follows:

[0025] 1) First, grow an undoped ZnO film on a glass substrate, the substrate temperature is 155°C, the coating reaction gas pressure is 130Pa, and the film thickness is 1000nm;

[0026] 2) Then grow a layer of B-doped ZnO film on the above-mentioned undoped ZnO film, the substrate temperature is 155°C, the coating reaction gas pressure is 130Pa, and the film thickness is 1000nm;

[0027] 3) Steps 1) and 2) above are repeated to obtain a ZnO thin film alternately grown in one cycle with a...

Embodiment 2

[0033] A method for preparing a ZnO film with a textured structure on a glass substrate, using diethyl zinc and water with a purity of 99.995% as source materials, and borane B 2 h 6 For the doping gas, dilute the doping gas borane B with hydrogen 2 h 6 , doping gas borane B 2 h 6 The volume percent concentration in the mixed gas is 1.0%, and metal organic chemical vapor deposition (MOCVD) is used to alternately grow the textured structure ZnO-TCO film on the glass substrate, the steps are as follows:

[0034] 1) First, grow an undoped ZnO film on a glass substrate, the substrate temperature is 155°C, the coating reaction gas pressure is 130Pa, and the film thickness is 100nm;

[0035] 2) Then grow a layer of B-doped ZnO film on the above-mentioned undoped ZnO film, the substrate temperature is 155°C, the coating reaction gas pressure is 130Pa, and the film thickness is 100nm;

[0036] 3) Steps 1) and 2) above were repeated to obtain 10 periods of alternately overlapped a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com