Alkaline proteinase coated micro-pill and preparation method thereof

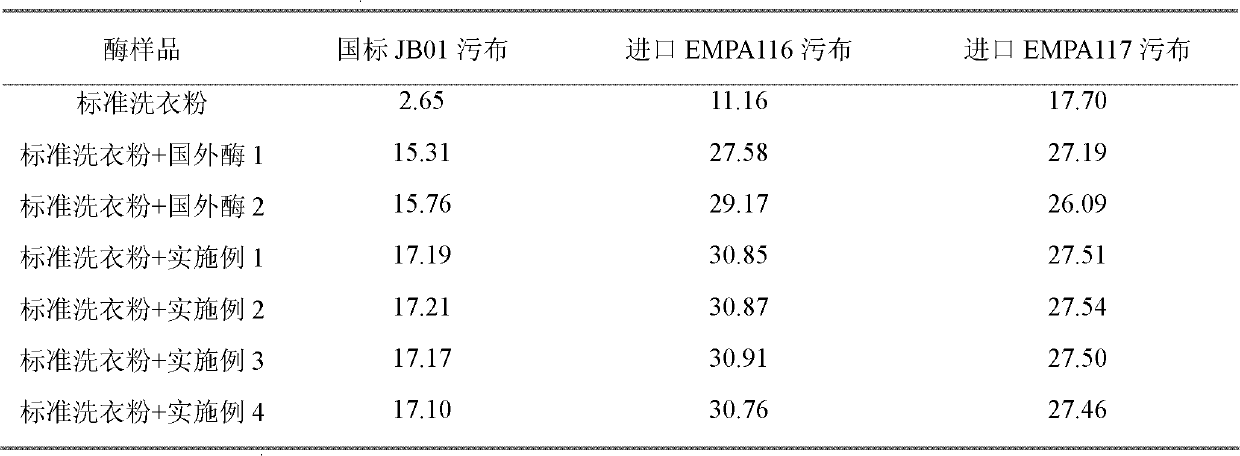

A technology of coating pellets and protease, which is applied in the direction of chemical instruments and methods, detergent compounding agents, detergent compositions, etc., can solve the problems of rough and irregular particles, poor heat and humidity resistance, and poor roundness, and achieve Fast dissolution speed, good heat and humidity resistance, good decontamination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] According to the proportion of alkaline protease powder 20%, dextrin 15%, starch 15%, soybean powder 30%, lactose 1%, sodium dodecylsulfonate 3%, microcrystalline cellulose 6%, corn steep liquor dry powder 10% Weigh each component of the pellet core respectively, 25kg in total, mix in a mixer for 30min, put into a centrifugal granulator, set the rotation speed at 600rpm, fan at 10Hz, use water as binder, and spray speed at 15rpm. After 40 minutes, release the pellets, place them in a fluidized bed, set the air inlet temperature to 40°C, and the air volume to 100m3 / h, dry to a material temperature of 35°C, release the dried pellets, and obtain the enzyme-containing pellet core.

[0016] Weigh each group of the coating layer according to the ratio of 30% dextrin, 10% starch, 15% polyvinyl alcohol, 1% sodium dodecylsulfonate, 20% sodium sulfate, 24% titanium dioxide, and 0.01% brilliant blue. Add water to make a suspension with a mass volume ratio of 5%, and pass through a...

Embodiment 2

[0018] According to the proportion of alkaline protease powder 60%, dextrin 5%, starch 10%, soybean powder 10%, lactose 3%, sodium dodecylsulfonate 1%, microcrystalline cellulose 7%, corn steep liquor dry powder 4% Weigh each component of the pellet core, 25kg in total, mix in a mixer for 30 minutes, put into a centrifugal granulator, set the rotation speed at 800rpm, fan at 14Hz, use water as a binder, and spray at a speed of 20rpm. After 30 minutes, release the pellets, place them in a fluidized bed, set the inlet air temperature at 50°C, and the air volume at 120m3 / h, dry until the material temperature is 40°C, release the dried pellets, and obtain the enzyme-containing pellet core.

[0019] According to the ratio of 15% dextrin, 30% starch, 5% polyvinyl alcohol, 6% sodium dodecylsulfonate, 13.9% sodium sulfate, 30% titanium dioxide, and 0.1% brilliant blue, each group of the coating layer was weighed. Add water to make a suspension with a mass-to-volume ratio of 7%, and pa...

Embodiment 3

[0021] According to the proportion of alkaline protease powder 30%, dextrin 10%, starch 30%, soybean powder 12%, lactose 2%, sodium lauryl sulfonate 1%, microcrystalline cellulose 10%, corn steep liquor dry powder 5% Weigh each component of the pellet core, 25kg in total, mix in a mixer for 30 minutes, put into a centrifugal granulator, set the rotation speed at 1000rpm, fan at 17Hz, use water as binder, and spray at a speed of 40rpm. After 25 minutes, release the pellets, place them in a fluidized bed, set the inlet air temperature to 80°C, and set the air volume to 160m3 / h, dry until the material temperature is 70°C, release the dried pellets, and obtain the enzyme-containing pellet core.

[0022] According to the ratio of 25% dextrin, 27% starch, 13% polyvinyl alcohol, 5% sodium dodecylsulfonate, 10% sodium sulfate, 20% titanium dioxide, and 0.02% brilliant blue, each group of the coating layer was weighed. Add water to make a suspension with a mass volume ratio of 7%, pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com