Preparation method for graphene based compound hydrogel modified with poly (N-isopropylacrylamide)

A technology of isopropylacrylamide and composite hydrogel, which is applied in the field of graphene hydrogel preparation, can solve problems such as inability to form three-dimensional graphene materials, and achieve high mechanical strength, high electrical conductivity, and broad application space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh 50mg of graphite oxide and add 50ml of deionized water, ultrasonically disperse at 200W power for 2 hours, after the dispersion is uniform, then weigh 2.5g of N-isopropylacrylamide and 250mg of potassium persulfate into the above graphite oxide aqueous solution, in a nitrogen atmosphere Continue ultrasonic dispersion for 60min (200W) under protection. Put the above precursor solution into the reaction kettle, raise the temperature to 100° C., and react for 12 hours. After the reaction is finished, the hydrogel product can be taken out.

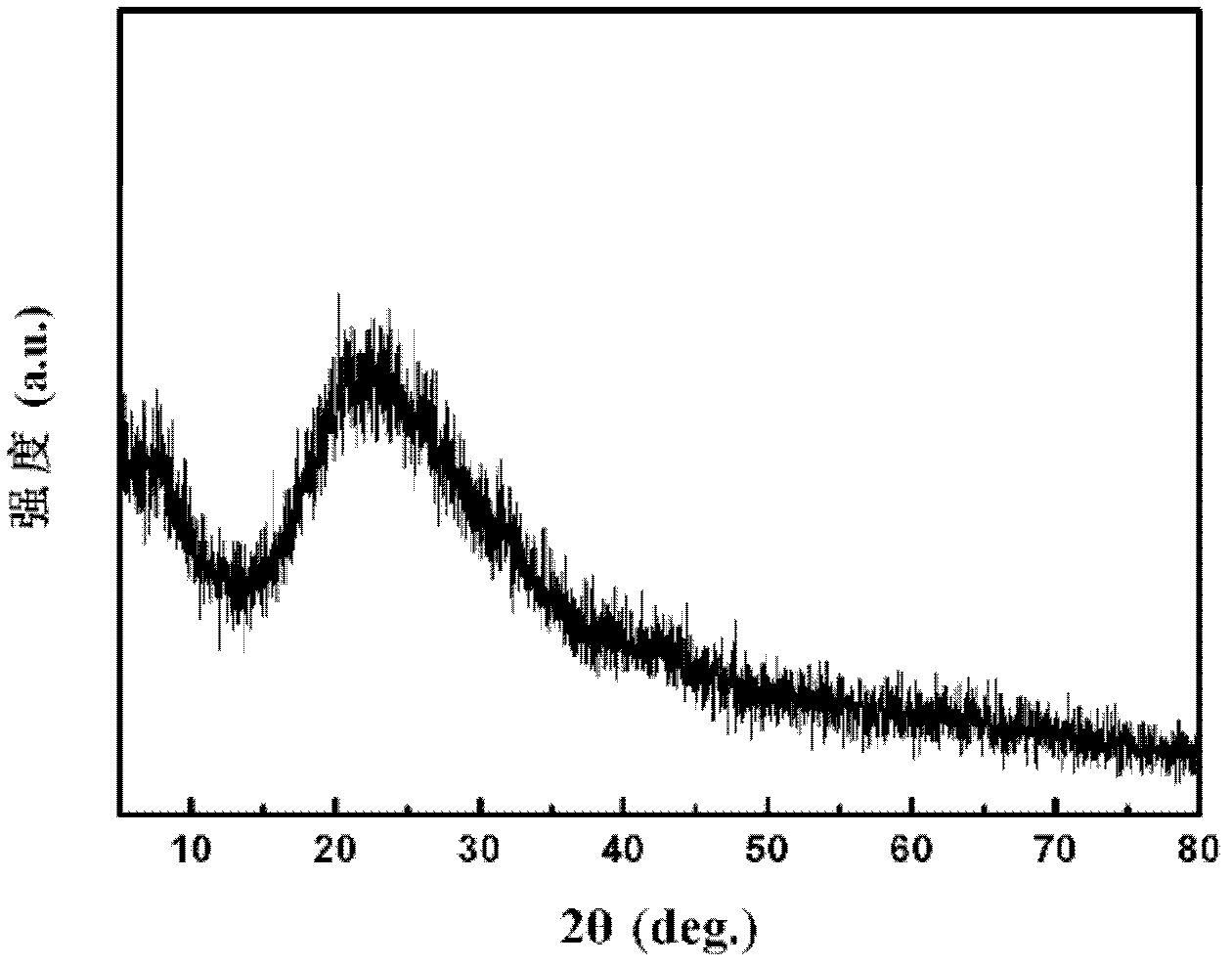

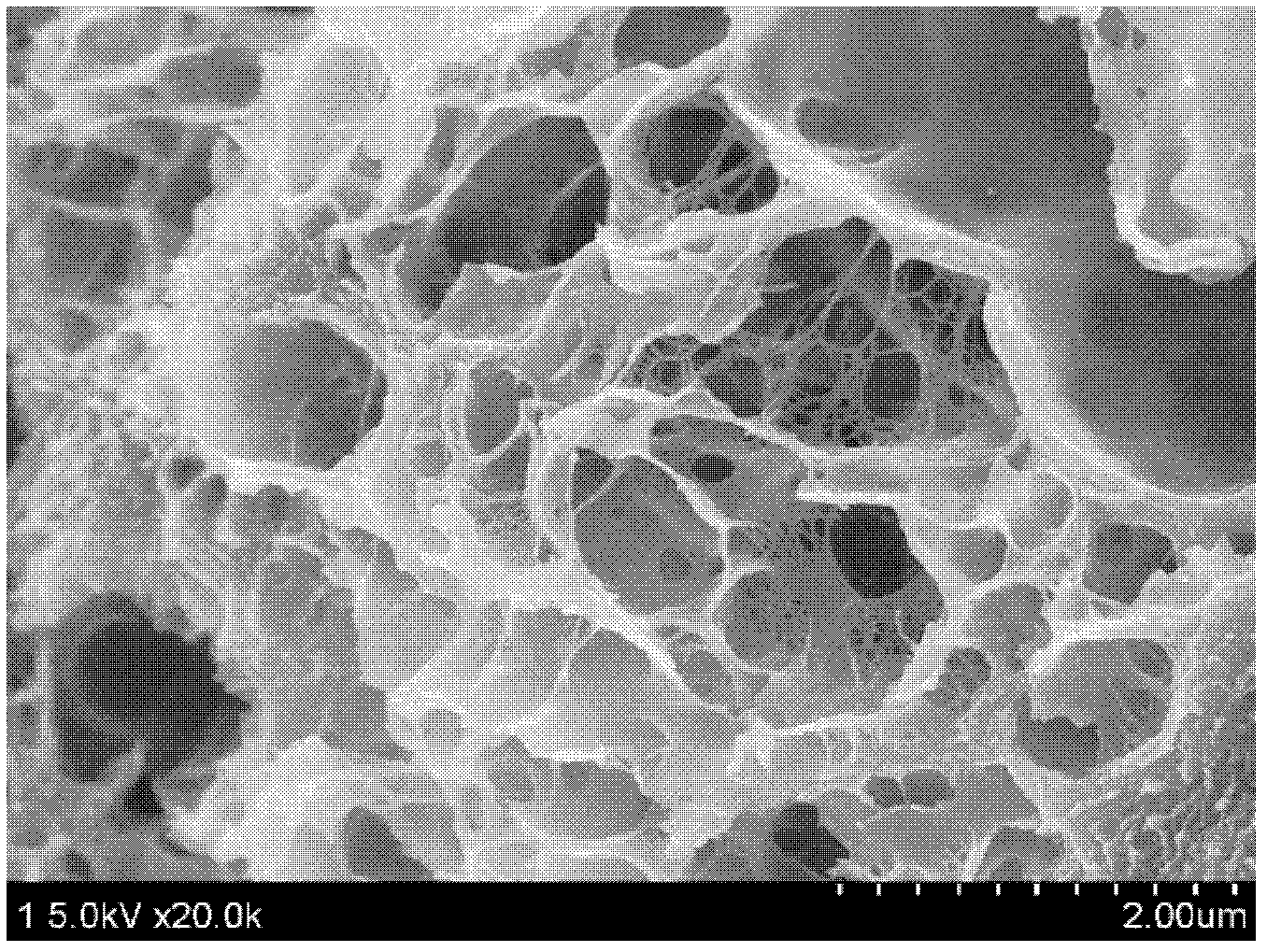

[0027] figure 1 It is the X-ray diffraction pattern of product, and the diffraction peak in the figure shows that graphite oxide is reduced into graphene. figure 2 It is the Fourier transform infrared spectrum of the product, and it can be seen that poly-N-isopropylacrylamide is contained in the composite hydrogel. image 3 It is a scanning electron microscope photo of the product. It can be seen that the hydrogel product cons...

Embodiment 2

[0029] Weigh 100mg of graphite oxide and add 50ml of deionized water, ultrasonically disperse at 300W power for 1.5h. Continue ultrasonic dispersion for 45min (300W) under protection. Put the above precursor solution into the reaction kettle, raise the temperature to 150°C, and react for 16h. After the reaction is finished, the hydrogel product can be taken out.

[0030] X-ray diffraction and Fourier transform infrared measurements showed that the composite hydrogel contained graphene and poly-N-isopropylacrylamide components, respectively. It was observed by scanning electron microscopy that the hydrogel product consisted of multi-layer graphene sheets to form a network skeleton structure, and poly-N-isopropylacrylamide was distributed in the intercalation of graphene sheets and between the skeleton structures. The graphene-based composite hydrogel product has high mechanical strength, good chemical stability, high electrical conductivity, and has a reversible swelling / de-s...

Embodiment 3

[0032] Weigh 200mg of graphite oxide and add 50ml of deionized water, ultrasonically disperse at 400W power for 1h, after the dispersion is uniform, then weigh 2g of N-isopropylacrylamide and 20mg of potassium persulfate into the above graphite oxide aqueous solution, protect Continue ultrasonic dispersion for 30min (400W). Put the above precursor solution into the reaction kettle, raise the temperature to 200°C, and react for 8 hours. After the reaction is finished, the hydrogel product can be taken out.

[0033] X-ray diffraction and Fourier transform infrared measurements showed that the composite hydrogel contained graphene and poly-N-isopropylacrylamide components, respectively. It was observed by scanning electron microscopy that the hydrogel product consisted of multi-layer graphene sheets to form a network skeleton structure, and poly-N-isopropylacrylamide was distributed in the intercalation of graphene sheets and between the skeleton structures. The graphene-based ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com