Blowing encapsulation all-in-one machine for plastic ampoule

A blow-fill-seal and all-in-one machine technology, which is applied in bottling machines, bottle filling, liquid handling, etc., can solve the problems of increased difficulty in control and debugging of transmission components, complex movement routes, etc., and achieves easy debugging and control, and conveying movement The effect of simple route and shortened transmission time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

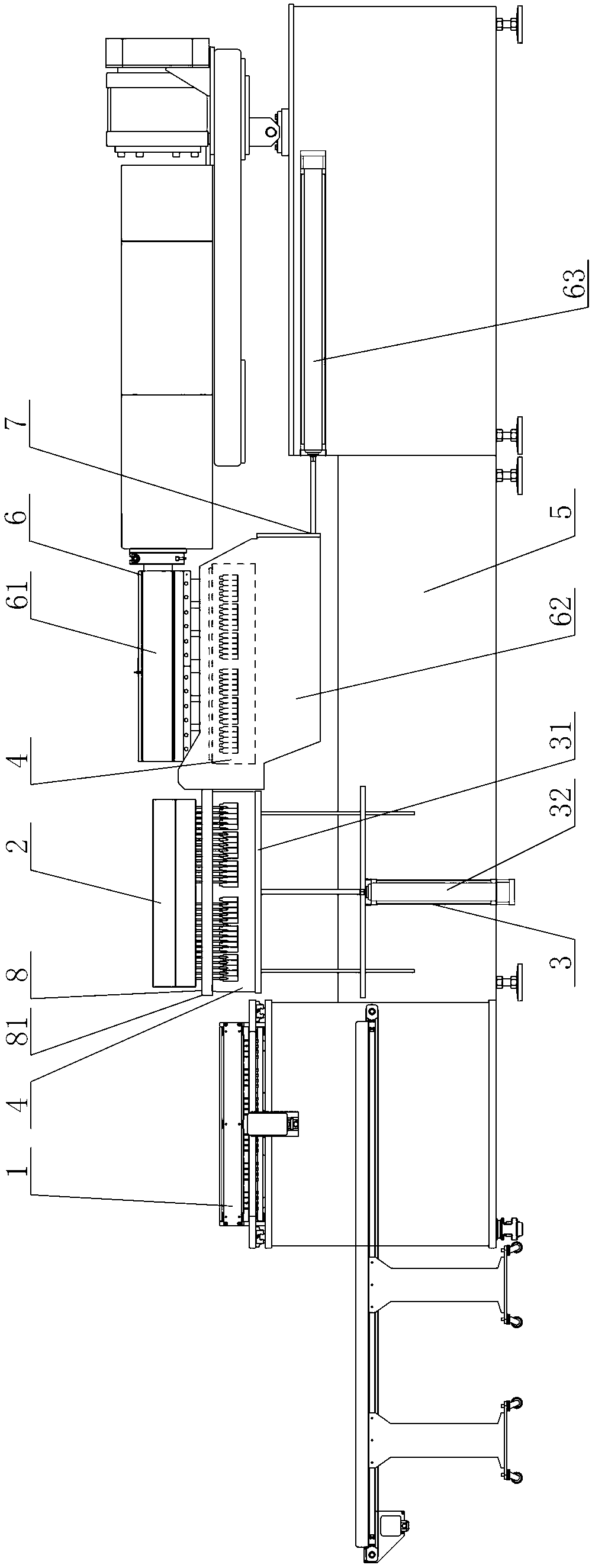

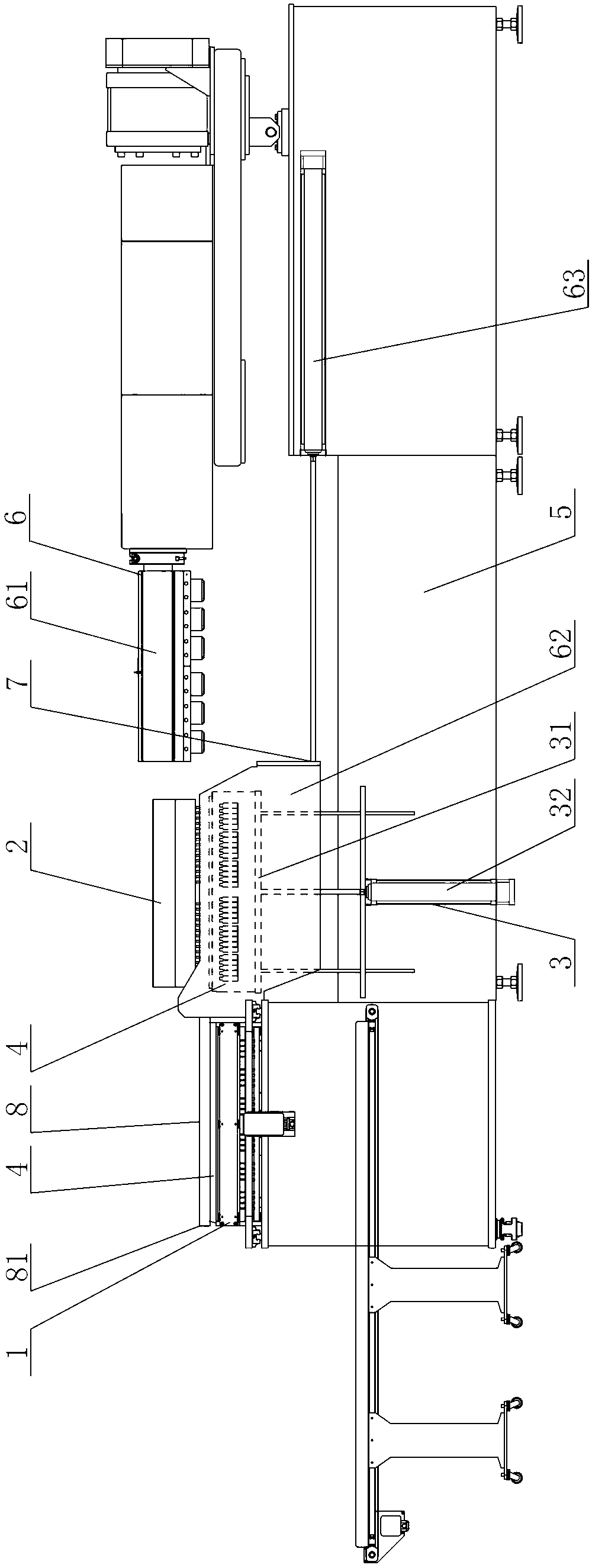

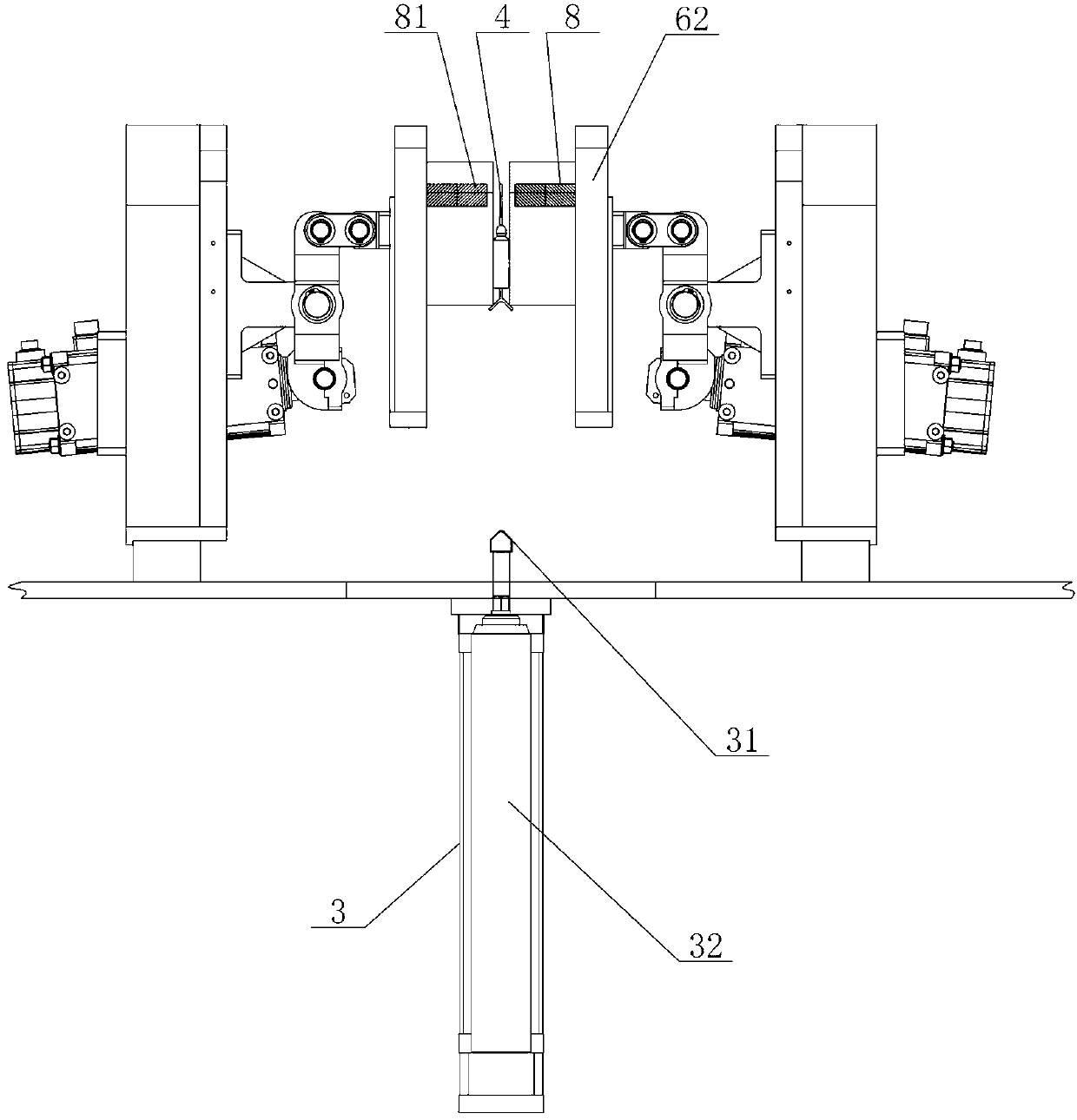

[0035] Figure 1 to Figure 5 It shows an embodiment of the integrated blow-fill-seal machine for plastic ampoules of the present invention, including a frame 5 and an extrusion bottle-making device 6 and a filling-sealing device 2 arranged on the frame 5 and arranged sequentially along the horizontal direction according to the process. 1. A die-cutting device 1, a potting positioning assembly 3 is provided below the potting station on the potting device 2, and the extruding bottle making device 6 is connected with the potting device 2 through the first conveying assembly 7 to complete the transmission of the bottle card 4 , the potting device 2 is connected with the die-cutting device 1 through the second transfer assembly 8 to complete the transfer of the bottle card 4 after potting. Compared with the existing production linkage lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com