Plastic ampoule blowing-filing and sealing integrated machine

A blow-fill-seal, all-in-one technology, used in bottling machines, bottle filling, liquid handling, etc., can solve the problems of complex movement routes, increased difficulty in control and debugging of transmission components, etc., and achieves easy connection and coordination, easy debugging and Control, the effect of convenient production control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

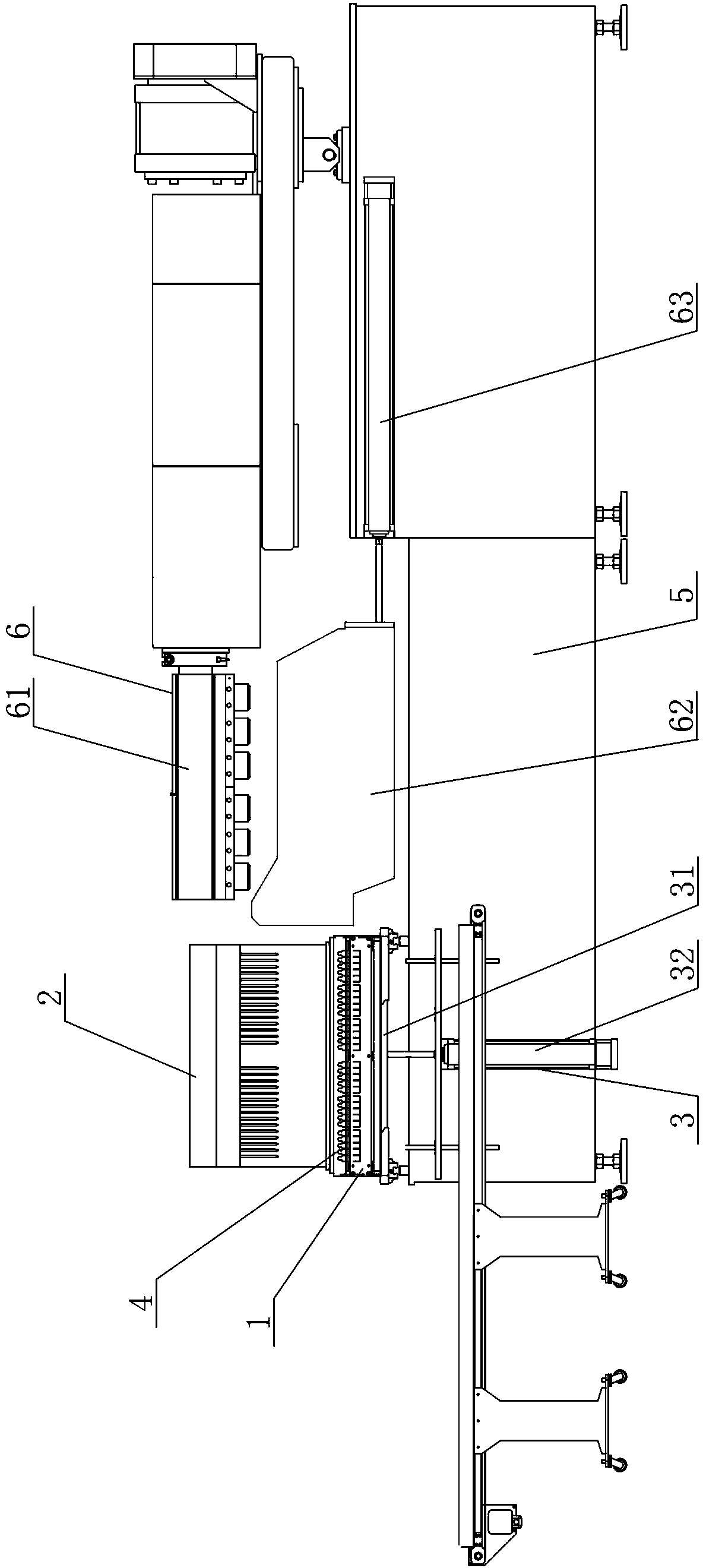

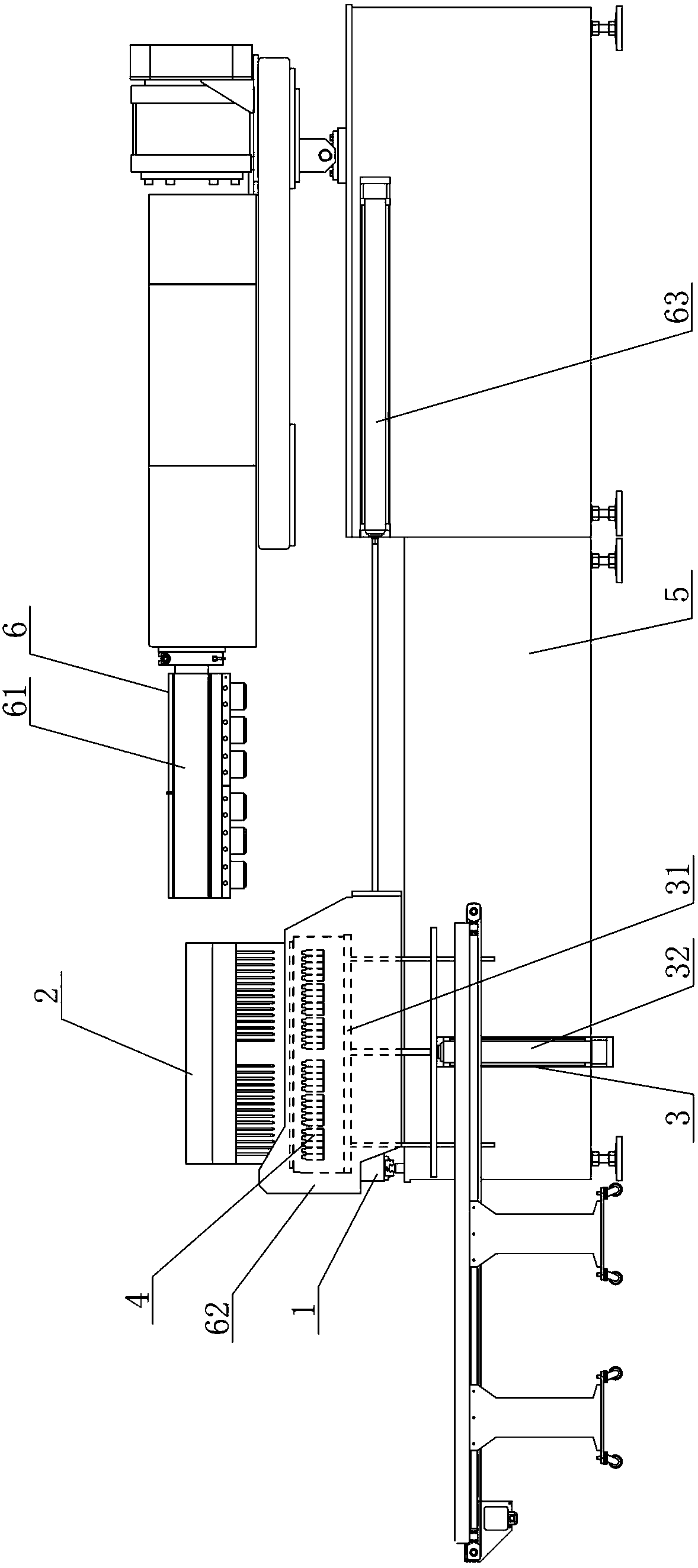

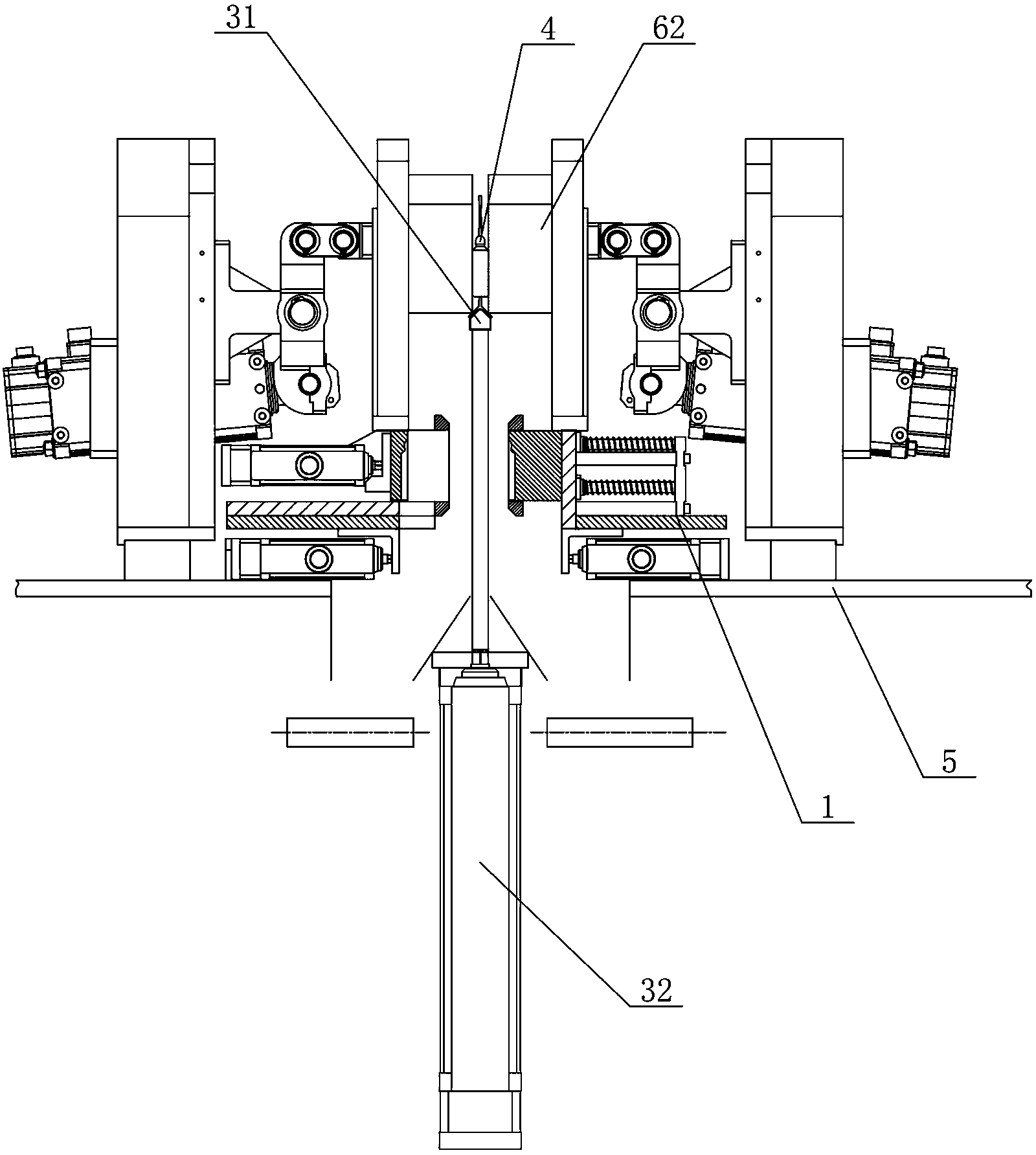

[0033] Figure 1 to Figure 5 It shows an embodiment of the plastic ampoule blow-fill-seal integrated machine of the present invention, including a frame 5 and a filling and sealing device 2, a die-cutting device 1, an extrusion bottle-making device 6, and a positioning assembly 3 arranged on the frame 5 , the die-cutting device 1 is located directly below the potting device 2, and the positioning assembly 3 is located under the potting device 2 and can take the bottle card 4 to the die-cutting station or the potting station through lifting movement. Compared with the existing plastic ampoule production linkage line, the installation and layout of each equipment in the plastic ampoule blow-fill-seal integrated machine of the present invention is compact, and the floor space is small, which greatly shortens the time for the bottle card ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com