Hydrogenation catalyst and preparation method thereof

A hydrogenation catalyst and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of high equipment cost, high labor intensity and complex process. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

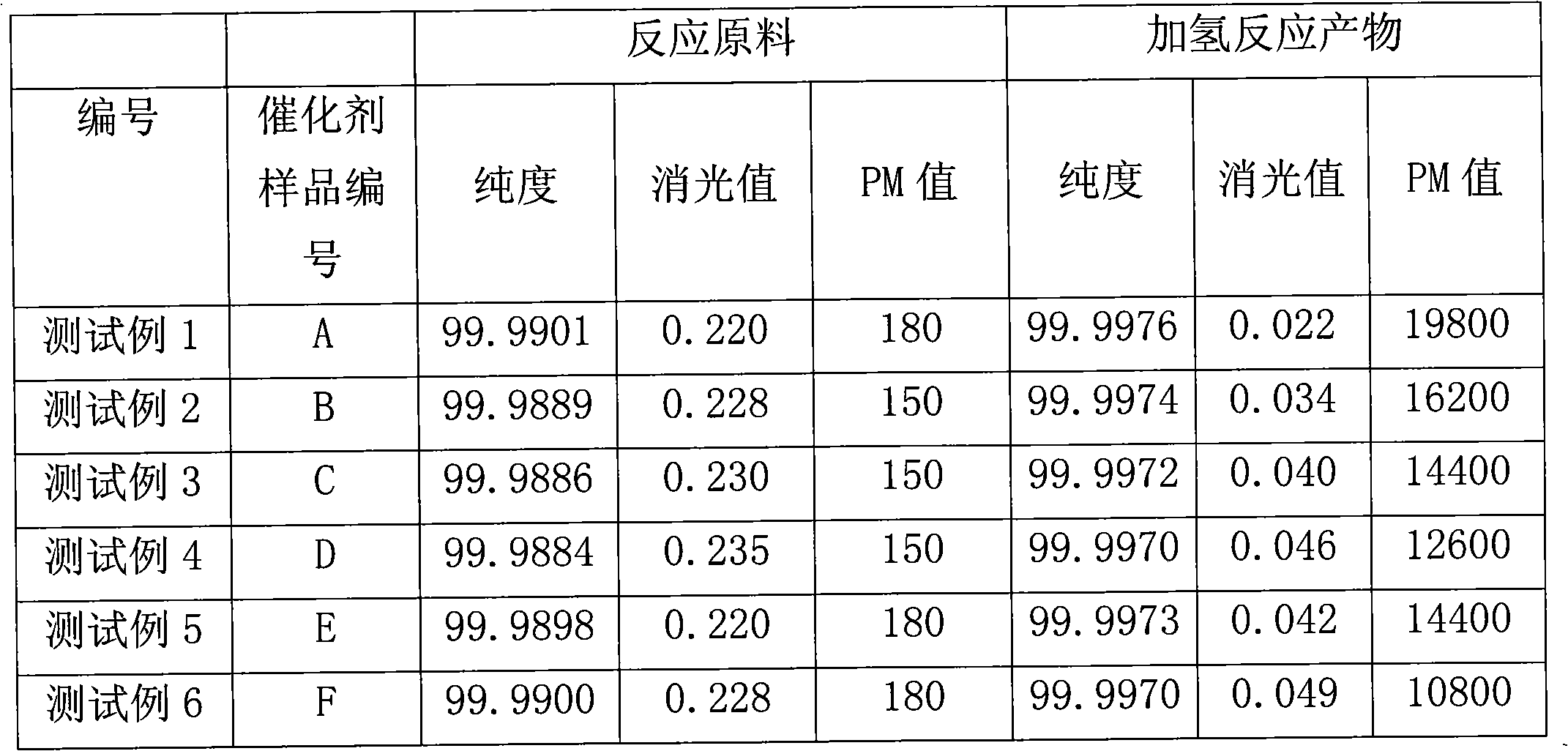

Examples

preparation example Construction

[0020] The preparation method of the hydrogenation catalyst provided by the present invention is characterized in that the method includes preparing a palladium-rare earth aqueous solution with a water-soluble palladium-containing compound, a water-soluble rare earth-containing compound and water, and impregnating the carrier with the palladium-rare earth aqueous solution to make the palladium-containing compound and The rare earth compound is supported on the carrier to obtain a catalyst precursor; after the catalyst precursor is dried and calcined, it is subjected to reduction treatment at 50-200°C under a hydrogen atmosphere to reduce the oxidized divalent palladium in the palladium compound to metallic palladium to obtain Catalyst products.

[0021] In the preparation method provided by the present invention, the water-soluble rare earth-containing compound is selected from La(NO 3 ) 3 ·6H 2 O, La(OAc) 3 ·5H 2 O, LaCl 3 ·7H 2 O, (III) Ce(NO 3 ) 3 ·6H 2 O, (IV) Ce(NO 3 ) 4 ·7H ...

Embodiment 1

[0027] This example illustrates 2%Pd-1%La 2 O 3 / Preparation process of activated carbon granular catalyst.

[0028] Treatment of activated carbon carrier: 104g of 4-10 mesh coconut shell granular activated carbon is put into a 500ml beaker, soaked in 300ml of water and stirred for 30min, washed and filtered. Soak in 200ml water and stir for 30min, wash and filter; repeat once. 200ml 0.5N nitric acid, slightly stir and soak for 60min, wash and filter. Wash the nitric acid with distilled water or deionized water to a pH of about 7.0, and dry at 100-110°C for 2-8 hours to obtain 100g of treated coconut shell granular activated carbon for use.

[0029] Prepare palladium-rare earth aqueous solution: weigh 5.1 grams of palladium nitrate Pd(NO 3 ) 2 ·2H 2 O (Fw = 266.5) and 2.74 grams of lanthanum nitrate La(NO 3 ) 3 ·6H 2 O (Fw=433) was dissolved in 120 g of water to obtain a palladium-rare earth aqueous solution.

[0030] Catalyst precursor: Pour the palladium-rare earth aqueous soluti...

Embodiment 2

[0033] This example illustrates 2%Pd-1%La 2 O 3 / Preparation process of activated carbon strip catalyst.

[0034] Treatment of activated carbon carrier: 103gΦ1.3mm, specific surface area greater than 1000m 2 / g coal strip activated carbon is put into a 500ml beaker, soaked in 300ml water and stirred for 30min, washed and filtered. Soak and stir in 200ml water for 30min, wash and filter; repeat once. 200ml 0.5N nitric acid, soak for 60min (slightly stirring), wash and filter. Wash the nitric acid with distilled water or deionized water to pH=7.0, and dry at 100-110°C for 2-8 hours to obtain 100g of treated strip-shaped granular activated carbon for use.

[0035] Prepare palladium-rare earth aqueous solution: weigh 5.1 grams of palladium nitrate Pd(NO 3 ) 2 ·2H 2 O (Fw = 266.5) and 2.74 grams of lanthanum nitrate La(NO 3 ) 3 ·6H 2 O (Fw=433) was dissolved in 120 g of water to obtain a palladium-rare earth aqueous solution.

[0036] Catalyst precursor: Pour the palladium-rare earth aq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com