Solid metal calcium-aluminum cored wire and preparation method thereof

A technology of metal calcium aluminum and metal calcium, which is applied in the field of metallurgical refining steel, can solve the problems of unstable deoxidation degree and refining effect of molten steel, inclusions cannot be floated and removed in time, unreasonable design of deoxidizer, etc., and achieves remarkable desulfurization effect, Enhancement of desulfurization effect and improvement of antioxidant capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

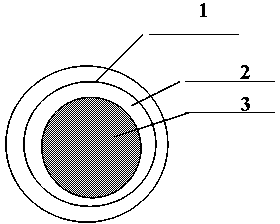

Image

Examples

Embodiment 1

[0022] Example 1: A steel factory with a nominal capacity of 300 tons of refined ladle uses the solid metal calcium aluminum cored wire provided by the present invention, and its inner core composition and content are: Ca: 23.26%, Al: 74.65 %, the rest are trace elements of Mg and Fe, wire diameter φ30. In the molten steel refining process, the solid core metal calcium aluminum cored wire is directly fed into the molten steel with a double-channel wire feeding machine. The wire feeding speed is 90-120m / min. The molten steel is always under the refining slag layer. The average recoveries of Ca and Al were 34.55% and 50.79%, respectively.

Embodiment 2

[0023] Example 2: A steel factory with a nominal capacity of 60 tons of refined steel ladle uses the solid metal calcium aluminum cored wire of the present invention, and the composition and content of the inner core are Ca: 89.92%, Al: 7.87%, and the rest are Mg, Fe trace elements, wire diameter φ8.0, in the molten steel refining process, the solid metal calcium aluminum cored wire is directly fed into the molten steel with a general-purpose wire feeding machine, the feeding speed is 170-200m / min, the feeding process Among them, the recovery rates of Ca and Al in molten steel were 23.67% and 67.21%, respectively.

Embodiment 3

[0024] Example 3: A steel factory with a nominal capacity of 120 tons of refined steel ladle uses the solid metal calcium aluminum cored wire proposed by the present invention, and the composition and content of the inner core are Ca: 44.97%, Al: 52.89% , the rest are Mg, Fe trace elements, wire diameter φ11.5. During the refining process of molten steel, the solid metal calcium-aluminum cored wire is directly fed into the molten steel with a general-purpose wire feeding machine, and the wire feeding speed is 130-160m / min. During the feeding process, the molten steel surges under the slag layer, Ca, The average recoveries of Al were 28.72 and 59.86%, respectively.

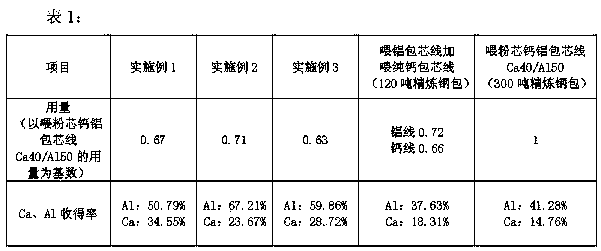

[0025] Comparative analysis with the existing aluminum feed wire plus pure calcium wire and powder core calcium aluminum wire Ca40 / Al50:

[0026] Table 1 shows the comparative analysis of the effects of Examples 1-3 provided by the present invention and the effects of separately feeding aluminum wire and pure calc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com