Method for preparing silicate ceramic pellets by using waste aeroconcrete building blocks

A technology of air-entrained concrete and silicate, which is applied in the field of resource utilization of inorganic solid waste, can solve the problems of large economic losses, affect the normal production of enterprises, and affect the healthy development of the aerated concrete industry, and achieve the effect of increasing the growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

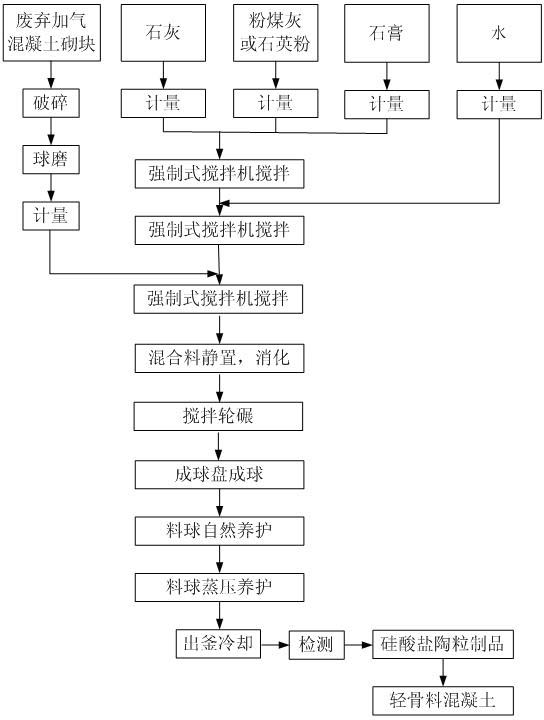

Method used

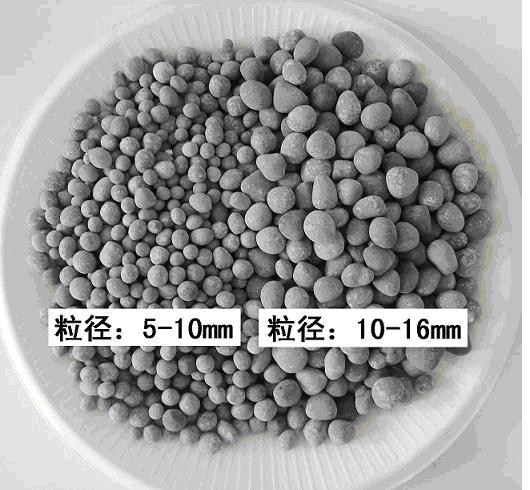

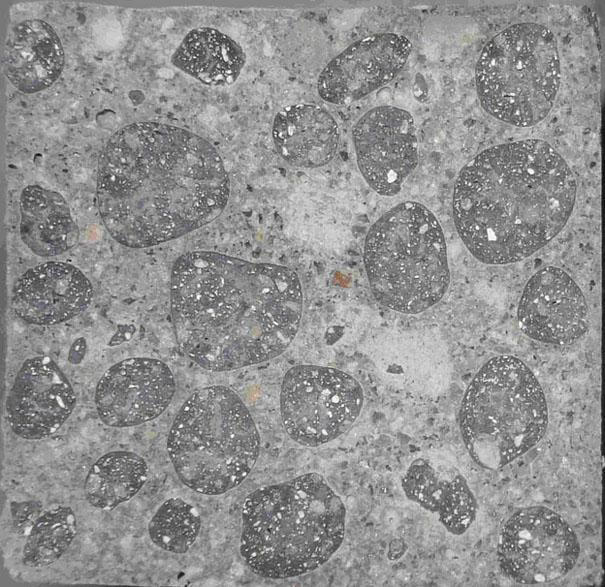

Image

Examples

Embodiment 1

[0044] Example 1: The present invention utilizes waste aerated concrete block to make the method for silicate ceramsite, comprises the following steps:

[0045] 1) After the aerated concrete block is broken, put it into a ball mill and grind it into powder, and the fineness is controlled to be ≤8% on a 180-mesh sieve.

[0046] 2) The effective calcium oxide content in the lime is determined to be 73.4%, the silica content in the quartz powder is 98.3%, the waste aerated concrete acid-insoluble matter is 36.4%, and the silica content in the acid-insoluble matter is 76.1%, then The content of unreacted silica in air-entrained concrete is 27.7%.

[0047] 3) Calculate the amount of each raw material used, and adjust the calcium-silicon ratio to 0.83.

[0048] Lime 100kg, quartz powder 100kg, gypsum powder 2.0kg, ground aerated concrete powder 10kg, mixing water 40kg.

[0049] Check the calcium-silicon ratio:

Embodiment 2

[0060] Example 2: The present invention utilizes waste aerated concrete block to make the method for silicate ceramsite, comprises the following steps:

[0061] 1) After the aerated concrete block is broken, put it into a ball mill and grind it into powder, and the fineness is controlled to be ≤8% on a 180-mesh sieve.

[0062] 2) The effective calcium oxide content in lime was determined to be 83.5%, the silicon dioxide content in fly ash was 53.3%, the waste aerated concrete acid-insoluble matter was 22.89%, and the silicon dioxide content in acid-insoluble matter was 62.91%. Then the content of unreacted silica in air-entrained concrete is 14.4%.

[0063] 3) Calculate the amount of each raw material used, and adjust the calcium-silicon ratio to 0.80.

[0064] Lime 100kg, fly ash 115kg, gypsum powder 2.2kg, ground aerated concrete powder 400kg, mixing water 100kg.

[0065] Check the calcium-silicon ratio:

[0066] Calcium Oxide = Calcium Oxide 石灰 =100*0.835=83.5...

Embodiment 3

[0076] Example 3: The present invention utilizes waste aerated concrete block to make the method for silicate ceramsite, comprises the following steps:

[0077] 1) After the aerated concrete block is broken, put it into a ball mill and grind it into powder, and the fineness is controlled to be ≤8% on a 180-mesh sieve.

[0078] 2) The effective calcium oxide content in lime was determined to be 78.1%, the silica content in fly ash was 55.3%, the acid-insoluble matter in waste aerated concrete was 29.4%, and the silica content in acid-insoluble matter was 57.48%. Then the content of unreacted silica in air-entrained concrete is 16.9%.

[0079] 3) Calculate the amount of each raw material used, and adjust the calcium-silicon ratio to 0.70.

[0080] Lime 100kg, fly ash 200kg, gypsum powder 3.0kg, ground aerated concrete powder 100kg, mixing water 80kg.

[0081] Check the calcium-silicon ratio:

[0082] Calcium Oxide = Calcium Oxide 石灰 =100*0.781=78.1

[0083] Si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Cylinder compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com