Water permeable bricks produced by using building waste residue and manufacturing method thereof

A technology of construction waste and permeable bricks, which is applied in the direction of construction, manufacturing tools, and pavements paved with prefabricated blocks, etc., can solve problems such as threats to the survival of animals and humans, epidemics of diseases, and air hazards, so as to improve air quality and protect the environment , the effect of reducing exhaust emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The concrete waste generated during the construction process, the waste glass, waste porcelain pieces, waste marble and granite fragments generated during the decoration and decoration process, the waste bricks and tiles and old wall waste solid waste generated during the old city renovation and demolition process are crushed , crushing, sorting, magnetic separation, drying, milling, and screening to make construction waste slag powder with a particle size of -1mm for use;

[0043] The waste glass fragments, waste glass bottles, waste glass produced in the construction site and home decoration process, which are screened out in the sorting process of domestic waste, are crushed, crushed, sorted, magnetically separated, dried, pulverized, and screened. After separation, the waste glass powder with a particle size of -1mm is made into stand-by;

[0044] The coal-fired power plant uses coal as fuel to produce a fine ash waste slag in the process of incinerating power gener...

Embodiment 2

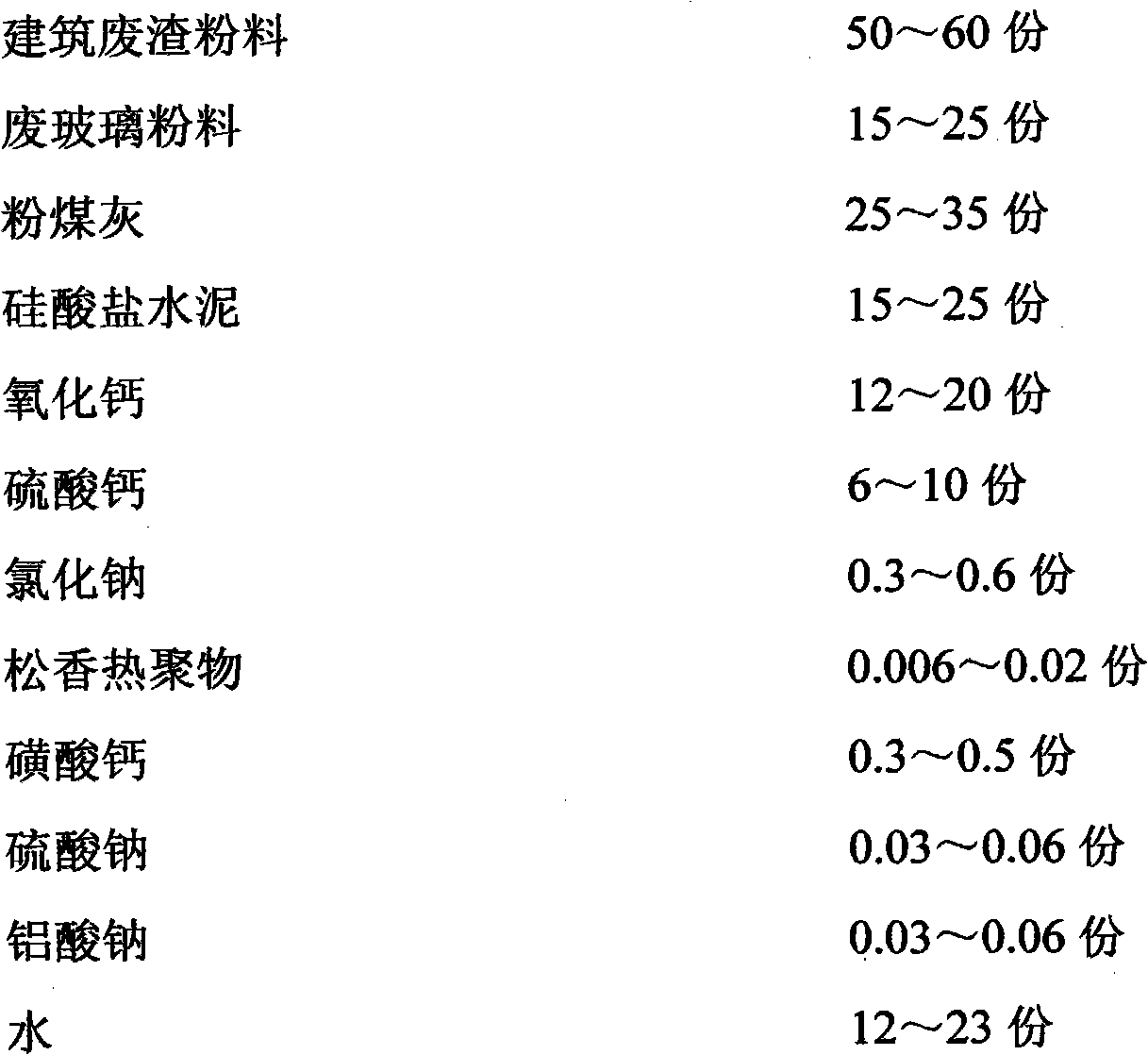

[0048] Get the construction waste slag powder 60kg of embodiment 1, waste glass powder 25kg, fly ash 35kg, Portland cement 25kg,-0.2mm calcium oxide 20kg,-0.2mm calcium sulfate 10kg, sodium chloride 0.6kg, rosin heat 0.02kg of polymer, 0.6kg of calcium sulfonate, 0.06kg of sodium sulfate, 0.06kg of sodium aluminate and 23kg of water are uniformly mixed. The lower layer of bricks is added to a biaxial mixing mixer and stirred until it becomes wet, and then extruded by mechanical vibration to form a permeable brick. For the lower brick, take 25kg of marble waste slag powder, 8kg of bentonite, 8kg of talcum powder, 2kg of iron oxide and 5kg of water for the upper brick, and use a secondary distributor to evenly spread a layer of fine material on the upper part of the lower brick. Under the pressure of 30Mpa, the construction waste slag permeable bricks are manufactured, and then the formed permeable bricks are sent to the autoclave for steam curing. First, the temperature is raise...

Embodiment 3

[0050] Get the construction waste slag powder 53kg of embodiment 1, waste glass powder 18kg, fly ash 28kg, Portland cement 18kg,-0.2mm calcium oxide powder 13kg,-0.2mm calcium sulfate 7kg, sodium chloride 0.4kg, rosin 0.008kg of thermal polymer, 0.4kg of calcium sulfonate, 0.04kg of sodium sulfate, 0.04kg of sodium aluminate and 15kg of water are mixed evenly. The lower layer of bricks is added to a twin-shaft mixing mixer and stirred until it becomes moist, and then extruded by mechanical vibration to form an ecological permeable For the lower layer of bricks, take 18kg of marble waste slag powder, 6.5kg of bentonite, 6.5kg of talcum powder, 1.5kg of iron oxide and 3.5kg of water for the upper layer of bricks, and use a secondary distribution machine to evenly spread it on the upper part of the lower layer of bricks. After a layer of fine material, under the pressure of 26Mpa, the building waste permeable bricks are made into permeable bricks, and then the formed permeable bri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com