Preparation method of bamboo fiber knitted terry fabric

A bamboo fiber and fabric technology, applied in knitting, fiber processing, weft knitting and other directions, can solve the problems of poor shrinkage and single function, and achieve the effects of good drape, improved comfort and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] weaving process

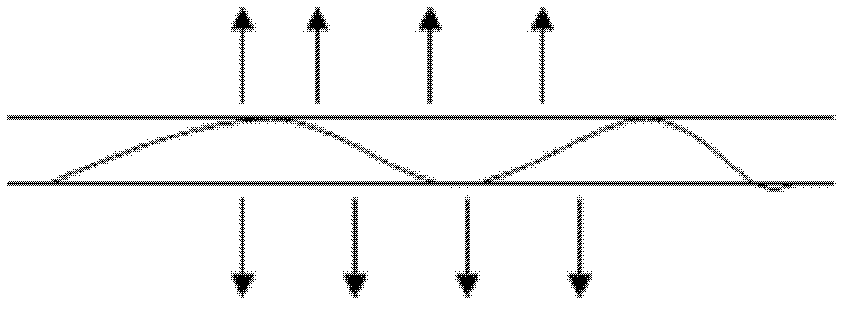

[0032] 1) Raw material preparation: the terry yarn is bamboo fiber, the linear density is Ne25, and the twist coefficient is 330; the ground yarn is polyester filament with special-shaped cross-section, and the linear density is 75D. Pre-condition humidity for 24 hours in a constant temperature and humidity environment with a temperature of 23°C and a humidity of 60% (attached figure 1 ).

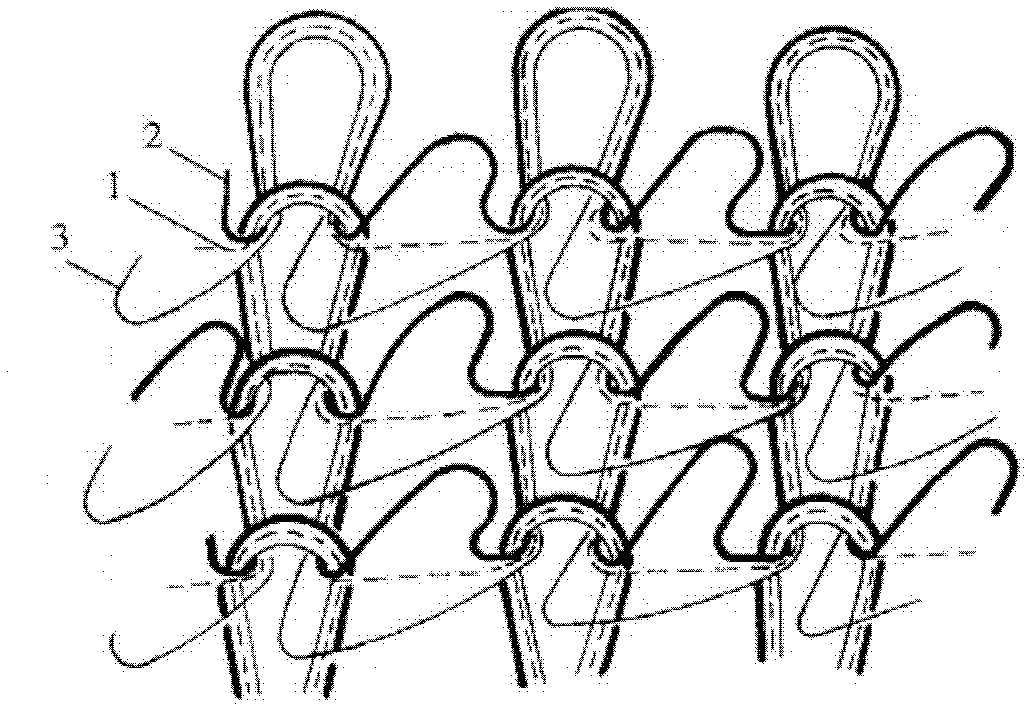

[0033] 2) Weaving on the upper machine: the selected machine number is 19G-24G, and the sinker nose type is 1.8mm-3.0mm. The organization structure is the terry structure of the package (see attached figure 2 ). When weaving, feed the loop yarn 1 and the ground yarn 2 into each piece at the same time, and adjust the vertical and horizontal angles of the yarns 1 and 2. In order to obtain a good terry coverage effect, the tension of the fed polyester filament should be greater than that of the terry yarn 1. At the same time, it is necessary to ensure that the l...

Embodiment 2

[0051] weaving process

[0052] 1) Raw material preparation: the terry yarn is bamboo fiber, the linear density is Ne50, and the twist coefficient is 345; the ground yarn is polyester filament with special-shaped cross-section, and the linear density is 100D. Pre-condition the humidity for 24 hours in a constant temperature and humidity environment with a temperature of 25°C and a humidity of 63%.

[0053] 2) Weaving on the upper machine: the selected machine number is 19G-24G, and the sinker nose type is 1.8mm-3.0mm. The organizational structure is a positively wrapped terry structure. The processing weight is 300g / m 2 .

[0054] The weaving scheme is as follows:

[0055] Option 1: The machine number is 19G, the sinker model is 1.8mm, the bamboo fiber yarn is 25s, and the special-shaped polyester filament is 100D.

[0056] Option 2: The machine number is 24G, the sinker model is 3mm, the bamboo fiber yarn is 50s, and the special-shaped polyester filament is 75D.

[0057...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| twist factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com