Paint special for curtain coating

A technology of curtain coating and parts by weight, applied in coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems of insulation performance, temperature resistance, UV resistance, rust resistance, and drying speed that cannot meet actual needs, etc. Achieve the effect of good insulation performance and excellent anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

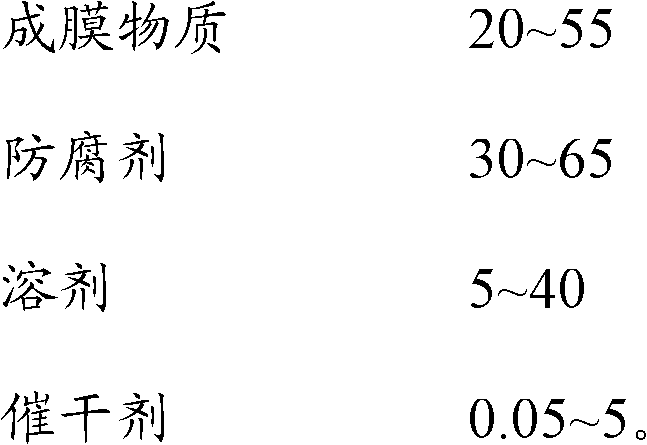

[0039] Prepare the special paint for curtain coating according to the following component distribution ratio, and its composition is according to parts by weight:

[0040]

[0041]

[0042] All the above raw materials are commercially available.

Embodiment 2

[0044] Prepare the special paint for curtain coating according to the following component distribution ratio, and its composition is according to parts by weight:

[0045]

Embodiment 3

[0047] Prepare the special paint for curtain coating according to the following component distribution ratio, and its composition is according to parts by weight:

[0048]

[0049] The preparation methods of Example 1, Example 2 and Example 3 are all prepared according to the methods recorded in the prior art, for example, obtained by a simple mixing process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com