Method for preparing vinyl chloride-vinyl acetate copolymer paste resin

A technology of vinyl acetate and vinyl chloride, which is applied in the field of preparation of vinyl chloride-vinyl acetate copolymer paste resin, can solve the problems of difficult control of process parameters, complex process, difficult quality control, etc., and achieves wide applicability, The effect of simple process and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The preparation method of first generation seed:

[0042] The emulsifier, pH adjuster, vinyl chloride monomer, desalted water and initiator are polymerized under anaerobic airtight conditions, the polymerization temperature is 50 ° C, and the time is 7 hours to obtain the first generation of seeds;

[0043] The first generation seed contains an emulsion with a particle size of 120nm and a weight solids content of 35%

[0044] The emulsifier is sodium dodecylbenzenesulfonate; the initiator is tert-butyl hydroperoxide;

[0045] The pH regulator is 20% ammonia by weight;

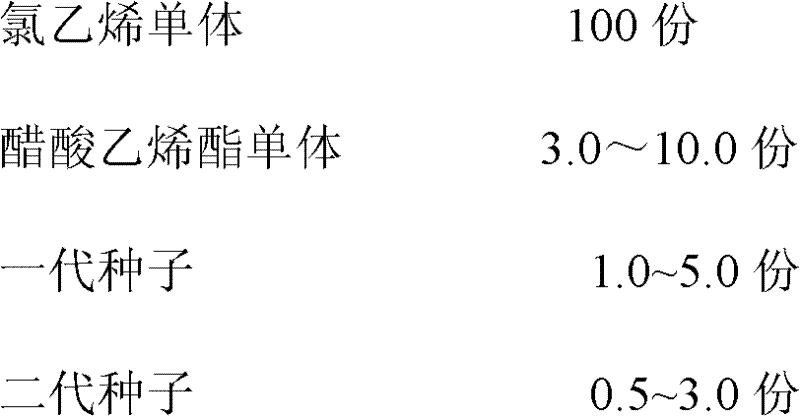

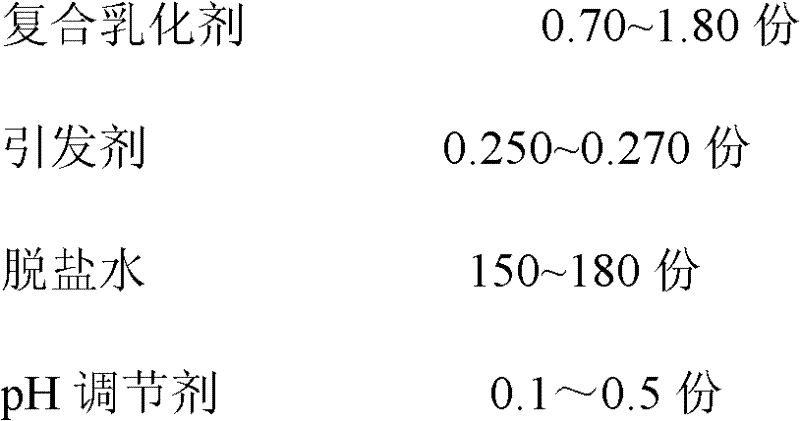

[0046] The parts by weight of each component are as follows:

[0047] 100 parts of vinyl chloride monomer, 2.0 parts of emulsifier, 0.5 part of pH regulator, 140 parts of desalted water, 0.260 parts of initiator;

[0048] The preparation method of second generation seed:

[0049] Including the following steps:

[0050] The composite emulsifier, initiator, desalinated water, pH regulator, and vinyl c...

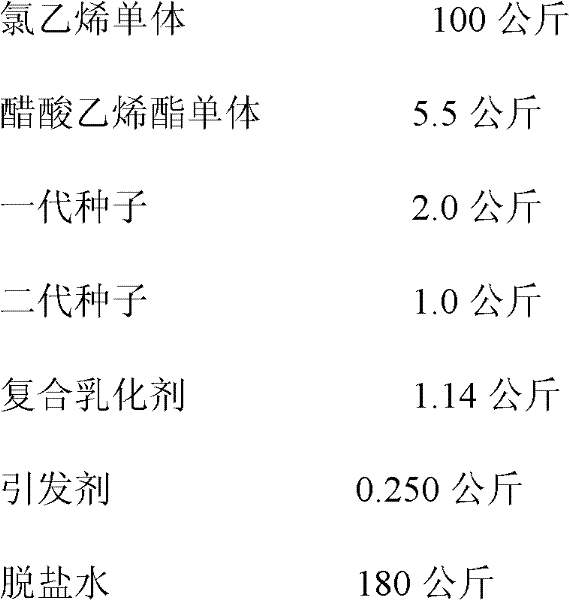

Embodiment 2

[0065] The preparation method of the first generation seed is the same as that of Example 1. Wherein, the parts by weight of each component are as follows:

[0066] 100 parts of vinyl chloride monomer, 2.0 parts of emulsifier, 0.5 part of pH regulator, 130 parts of desalted water, 0.260 parts of initiator;

[0067] The emulsifier is nonyl aryl polyether alcohol;

[0068] The first generation seed contained an emulsion with a particle size of 110 nm and a weight solids content of 37%.

[0069] The preparation method of second generation seed is identical with embodiment 1. Wherein: the parts by weight of each component are as follows:

[0070] 100 parts of vinyl chloride monomer, 1.90 parts of composite emulsifier, 0.25 parts of initiator, 160 parts of desalted water, 0.5 part of pH regulator;

[0071] The composite emulsifier is a mixture of stearyl alcohol and sodium dihexyl thiosuccinate with a weight ratio of 1.0:0.5.

[0072] The second-generation seed contains an emu...

Embodiment 3

[0082] The preparation method of first-generation seeds and second-generation seeds is basically the same as in Example 1.

[0083] The first-generation seed is an emulsion containing particles with a particle size of 130nm and a weight solid content of 33%;

[0084] The second-generation seed is an emulsion containing particles with a particle size of 900nm and a weight solid content of 26%.

[0085] Vinyl chloride-vinyl acetate copolymer emulsion preparation method:

[0086] The compound emulsifier, initiator, desalinated water, pH regulator, first-generation seed, second-generation seed, vinyl acetate and vinyl chloride monomer are polymerized under anaerobic and closed conditions. The polymerization temperature is 47°C and the time is 8 hours, to prepare vinyl chloride-vinyl acetate copolymer water suspension, and then recover the unreacted vinyl chloride monomer, replace with nitrogen, collect the emulsion, and obtain colloidal particles with an average diameter greater ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com