Method for extracting active polysaccharides from brown algae

A technology for active polysaccharide and brown algae, which is applied in the field of extracting active ingredients of natural products, can solve the problems of ecological environment threat, single product variety, water and energy consumption pollution, etc., and achieves the effects of improving yield, reducing toxic side effects and good water solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

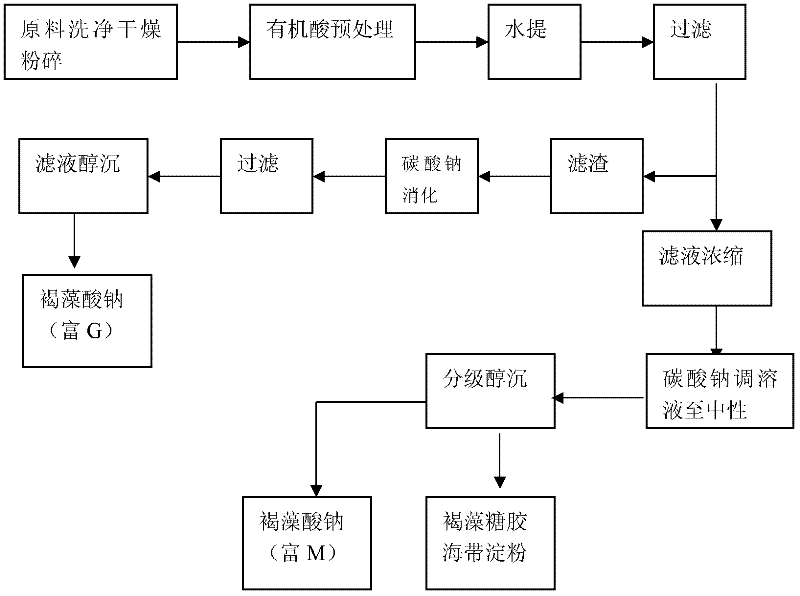

[0040] Such as figure 1 The process schematic diagram shown is carried out according to the following process:

[0041] 1) 1.5kg dry kelp powder is placed in a 10L extraction container;

[0042] 2) Take 1L of anhydrous formic acid and add 0.5L of water to make 1.5L of formic acid solution;

[0043] 3) Add 1.5L of the formic acid solution in step 2) to the extraction container in step 1), and stir fully to make the kelp powder evenly wet;

[0044] 4) The wetted material obtained in step 3) was heated to 100° C., kept warm for 20 minutes, and then distilled under reduced pressure until there was no obvious liquid in the extraction container.

[0045] 5) Add 5L of absolute ethanol to the extraction container after the vacuum distillation in step 4), fully stir, filter, and recover the ethanol by distillation of the filtrate, and the filter residue is dried kelp powder after organic acid pretreatment.

[0046] 6) Take 100 grams of organic acid pretreated kelp powder in step 5),...

Embodiment 2

[0056] 1) 1.5kg dry hijiki powder is placed in the extraction container;

[0057] 2) Take 180g of oxalic acid and add 2.0L of water to make an oxalic acid solution;

[0058] 3) Take 2L of the oxalic acid solution in step 2), add it to the extraction container in step 1), and stir fully to make the dried hijiki powder evenly wet;

[0059] 4) The material in step 3) was heated to 80° C., kept warm for 20 minutes, and then distilled under reduced pressure (the working pressure in the extraction container was 100 mmHg), until there was no obvious liquid in the extraction container.

[0060] 5) Add 5L of absolute ethanol to the extraction container after the vacuum distillation in step 4), fully stir, filter, and distill the filtrate to recover ethanol and oxalic acid, and the filter residue is dried to obtain organic acid pretreated hijiki powder.

[0061] 6) Take 100 grams of hijiki powder pretreated with organic acid in step 5), put it into a 1L beaker, add 500ml of distilled w...

Embodiment 3

[0070] 1) 1.5Kg dry macroalgae powder is placed in a 10L extraction container;

[0071] 2) Take 0.8L of anhydrous acetic acid and add 0.2L of water to prepare 1L of acetic acid solution;

[0072] 3) Take 1 L of the acetic acid solution in step 2), add it to the extraction container in step 1), stir well to make it evenly wet;

[0073] 4) The wetted material in step 3) was heated to 60° C., kept warm for 60 minutes, and then distilled under reduced pressure to remove the organic acid solution until there was no obvious liquid in the extraction container.

[0074] 5) After step 4), 5L of methanol was added to the container, fully stirred, filtered, and the filtrate was distilled to recover methanol, and the filter residue was dried to be the organic acid pretreated macroalgae powder;

[0075] 6) Take 100 grams of organic acid pretreated macroalgae powder dried in step 5), put it into a 1L beaker, add 500ml of distilled water, extract in a hot water bath at 70°C for 40 minutes, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com