Silicon carbide ramming material high in abrasion resistance and application thereof

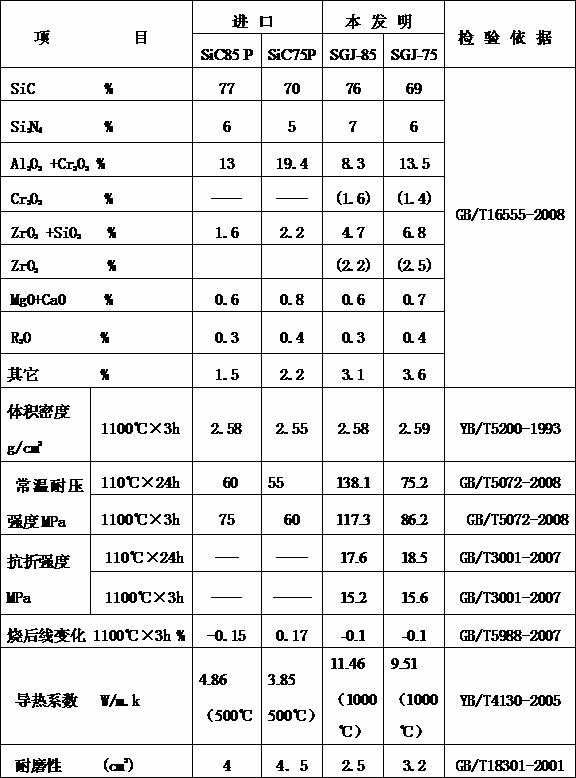

A wear-resistant silicon carbide and ramming material technology is applied in the field of high wear-resistant silicon carbide ramming materials, which can solve the problems of short service life and achieve the effects of long service life, high heat transfer coefficient and improved erosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Combine 55 parts of super-grade silicon carbide, 15 parts of α-type silicon nitride, and 10 parts of zirconium corundum (using high-zirconium corundum, of which ZrO 2 The content of 40%), 3.2 parts of alumina powder (3um) and 2 parts of silica powder (8um), 13 parts of 50% aluminum chromium phosphate aqueous solution, coagulant is active ρ-alumina 1 part and magnesium oxide 0.5 0.3 parts of explosion-proof fiber with a diameter of 1.5μm.

[0020] The above-mentioned raw materials are mixed and stirred in a forced mixer for 3-5 minutes. After the mixing and stirring are uniform, they are rammed and formed on the inner wall of the gasification furnace. After natural curing at 10 degrees Celsius for 6 hours, the ramming material is finally set and formed. The ramming material lining is heated at 7~9℃ / h to 540℃ in the oven process, and after holding for 16~18h, the aluminum chromium phosphate colloid forms P 2 O 5 -Al 2 O 3 -Cr 2 O 3 The composite reacts with the mixture in a s...

Embodiment 2

[0022] Combine 57 parts of special grade silicon carbide, 14 parts of α-type silicon nitride, and 7 parts of zirconium corundum (using high-zirconium corundum, of which ZrO 2 The content of 40%), 3.3 parts of alumina powder (4um), 1.5 parts of silica powder (8um), 12 parts of 60% aluminum chromium phosphate aqueous solution, coagulant is 2.5 parts of active ρ-alumina and 0.5 parts of oxidation Magnesium, 2.5 parts of bismuth iodoxy tannate, 0.7 parts of explosion-proof fiber with a diameter of 2.5 μm.

[0023] After the above-mentioned raw materials are uniformly mixed and stirred in a forced mixer, they are rammed and formed on the inner wall of the gasification furnace, and after natural solidification at 25 degrees Celsius for 8 hours, the ramming material is finally set and formed. The ramming material lining is heated at 7~9℃ / h to 540℃ in the oven process, and after holding for 16~18h, the aluminum chromium phosphate colloid forms P 2 O 5 -Al 2 O 3 -Cr 2 O 3 The composite rea...

Embodiment 3

[0026] Combine 65 parts of special grade silicon carbide, 10 parts of α-type silicon nitride, and 6 parts of zirconium corundum (using high-zirconium corundum, of which ZrO 2 The content of 40%), 6 parts of alumina powder (3um), 2.5 parts of silica powder (6um), 10 parts of 55% aluminum chromium phosphate aqueous solution, coagulant is 2 parts of active ρ-alumina and 0.4 parts of oxidation A mixture of magnesium, 1.5 parts of bismuth iodoxytan, 0.5 parts of explosion-proof fiber with a diameter of 2 μm.

[0027] After the above-mentioned raw materials are uniformly mixed and stirred in a forced mixer, they are rammed and formed on the inner wall of the gasification furnace, and after natural solidification in an environment of 30 degrees Celsius for 7 hours, the ramming material is finally set and formed. The ramming material lining is heated at 7~9℃ / h to 540℃ in the oven process, and after holding for 16~18h, the aluminum chromium phosphate colloid forms P 2 O 5 -Al 2 O 3 -Cr 2 O...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com