Multifunctional health care composite material

A composite material, multi-functional technology, applied in electrical components, inductor/transformer/magnet manufacturing, circuits, etc., can solve the problems of difficult to meet the needs of multi-faceted composite types, single health care function, similar materials, etc., to achieve excellent adsorption function , Promote blood circulation, promote the effect of excretion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

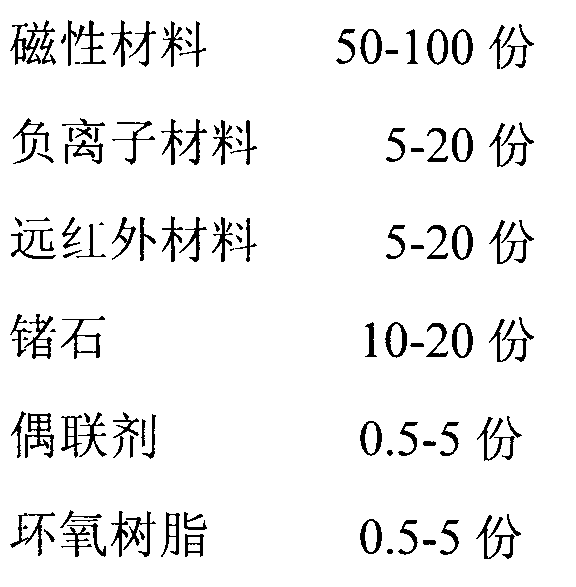

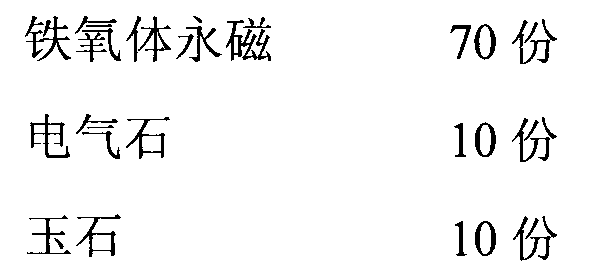

[0034] The multifunctional health care composite material is made up of the following materials by weight:

[0035]

[0036] The preparation method is as follows:

[0037] 1) Weigh and mix the above-mentioned ferrite permanent magnet, tourmaline, jade and germanium materials respectively, and crush them to a fineness of 1um;

[0038] 2) 1 kg of coupling agent and 1 kg of epoxy resin are added to the mixture obtained in step 1) and fully mixed;

[0039] 3) The mixture obtained in step 2) is magnetized and molded using a magnetizing compression molding machine, and the magnetic field strength reaches 1000 Gauss;

[0040] 4) Sintering the molded material obtained in step 3) at a temperature of 250° C. for 30 minutes to obtain a finished magnet.

[0041] A healthy quilt with health care function can be obtained by embedding the magnet obtained in the above steps in the quilt core of the quilt.

Embodiment 2

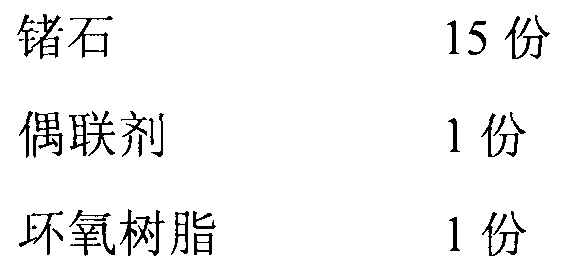

[0043] The multifunctional health care composite material is made up of the following materials by weight:

[0044]

[0045] The preparation method is as follows:

[0046] 1) Weigh and mix the above-mentioned NdFeB permanent magnet, tourmaline, meteorite and germanium stone materials respectively, and crush them to a fineness of 0.5um;

[0047] 2) 0.5kg of coupling agent and 0.5kg of epoxy resin are added to the mixture obtained in step 1) and fully mixed;

[0048] 3) The mixture obtained in step 2) is magnetized and molded using a magnetizing compression molding machine, and the magnetic field strength reaches 800 Gauss;

[0049] 4) Sintering the molded material obtained in step 3) at a temperature of 150° C. for 30 minutes to obtain a finished magnet.

[0050] A healthy pillow with health care function can be obtained by embedding the magnet obtained in the above steps in the pillow core of the pillow.

Embodiment 3

[0052] The multifunctional health care composite material is made up of the following materials by weight:

[0053]

[0054] The preparation method is as follows:

[0055] 1) Weigh and mix the above-mentioned samarium-cobalt permanent magnet, tourmaline, meteorite and germanium stone materials respectively, and crush them to a fineness of 0.5um;

[0056] 2) 5kg of coupling agent and 5kg of epoxy resin are added in the mixture obtained in step 1) and fully mixed;

[0057] 3) The mixture obtained in step 2) is magnetized and molded using a magnetizing molding machine, and the magnetic field strength reaches 1500 Gauss;

[0058] 4) Sintering the molded material obtained in step 3) at a temperature of 300° C. for 60 minutes to obtain a finished magnet.

[0059] A healthy pillow with health care function can be obtained by embedding the magnet obtained in the above steps in the pillow core of the pillow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com