Method for preparing nuclear functional material tungsten-tantalum alloy plate

A technology of functional materials and tantalum alloys, which is applied in the field of preparation of tungsten-tantalum alloy plates for nuclear functional materials, to achieve the effects of uniform composition, uniform structure and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

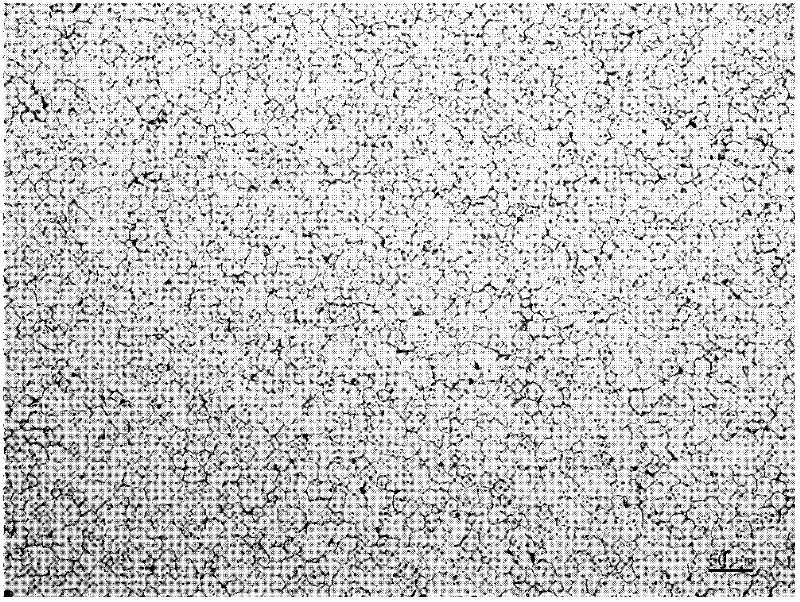

Image

Examples

Embodiment 1

[0027] Step 1. Place tungsten powder (mass purity not less than 99.95%) with a Fischer average particle size of 3.0 μm and tantalum powder (mass purity not less than 99.95%) with a Fischer average particle size of 5.0 μm in a mass ratio of 9.5:0.5 In the planetary ball mill, stainless steel ball milling jars and stainless steel balls were used, absolute ethanol was used as the ball milling medium, and the vacuum degree was not greater than 0.1Pa, the ball-to-material ratio was 8:1, and the rotational speed was 150r / min. Under the conditions of high-energy ball milling for 5 hours, Tungsten and tantalum mixed powder; during the vacuum high-energy ball milling process, high-purity argon gas with a mass purity of not less than 99.99% is used as the protective atmosphere;

[0028] Step 2. Compress the tungsten-tantalum mixed powder described in step 1 with a cold isostatic press to obtain a tungsten-tantalum alloy plate green body; the pressure of the compression molding is 230 MPa...

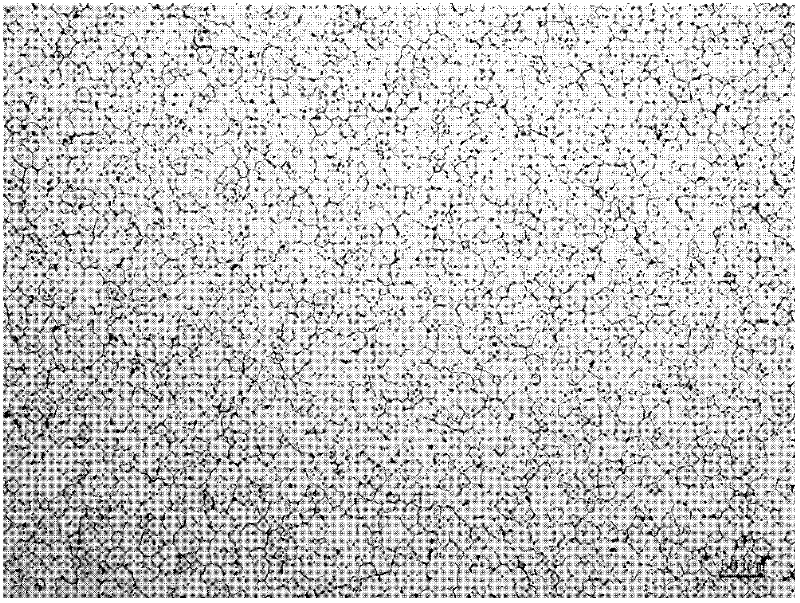

Embodiment 2

[0033] Step 1, place tungsten powder (mass purity not less than 99.95%) with a Fischer average particle size of 6.0 μm and tantalum powder (mass purity not less than 99.95%) with a Fischer average particle size of 7.0 μm in a mass ratio of 9.5:0.5 In the planetary ball mill, stainless steel ball milling pots and stainless steel balls are used, absolute ethanol is used as the ball milling medium, vacuum high-energy ball milling is carried out for 4 hours under the conditions of a vacuum degree of not more than 0.1 Pa, a ball-to-material ratio of 8:1, and a rotational speed of 185 r / min. Obtain tungsten-tantalum mixed powder; during the vacuum high-energy ball milling process, high-purity argon with a mass purity of not less than 99.99% is used as a protective atmosphere;

[0034] Step 2. Compress the tungsten-tantalum mixed powder described in step 1 with a cold isostatic press to obtain a tungsten-tantalum alloy plate green body; the pressure of the compression molding is 150 M...

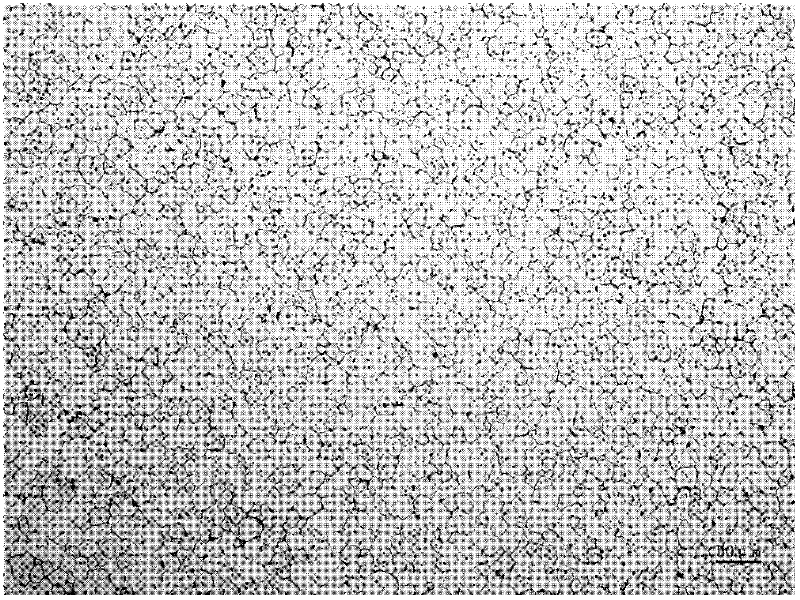

Embodiment 3

[0039] Step 1. Place tungsten powder (mass purity not less than 99.95%) with a Fischer average particle size of 8.0 μm and tantalum powder (mass purity not less than 99.95%) with a Fischer average particle size of 8.0 μm in a mass ratio of 9.5:0.5 In the planetary ball mill, a stainless steel ball mill pot and stainless steel balls are used, with absolute ethanol as the ball milling medium, vacuum high-energy ball milling for 3 hours under the conditions of a vacuum degree of not more than 0.1Pa, a ball-to-material ratio of 8:1, and a rotational speed of 225r / min. Obtain tungsten-tantalum mixed powder; during the vacuum high-energy ball milling process, high-purity argon with a mass purity of not less than 99.99% is used as a protective atmosphere;

[0040] Step 2. Compress the tungsten-tantalum mixed powder described in step 1 with a cold isostatic press to obtain a tungsten-tantalum alloy plate green body; the pressure of the compression molding is 300MPa, and the holding tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com