Protective film for automotive wheel

A technology for protecting films and wheels, applied to wheels, film/sheet-like adhesives, wheel cover plates, etc., to prevent cracking, glue residue, and rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

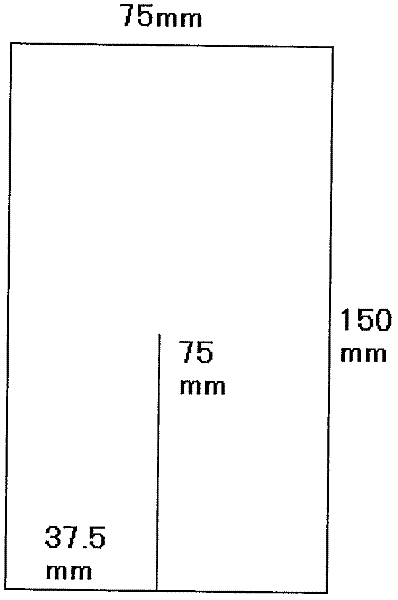

Image

Examples

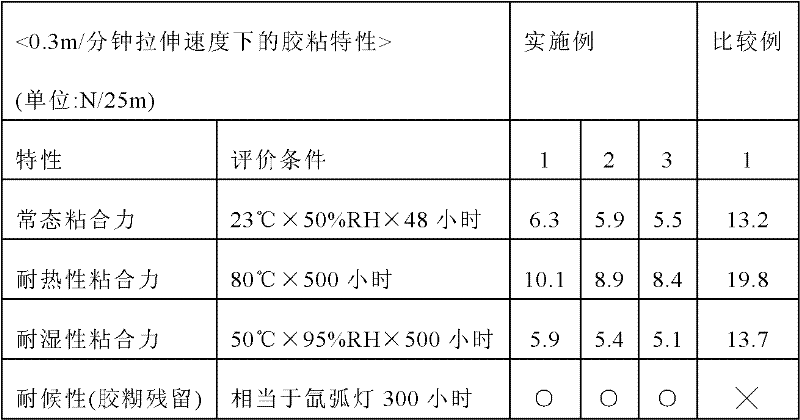

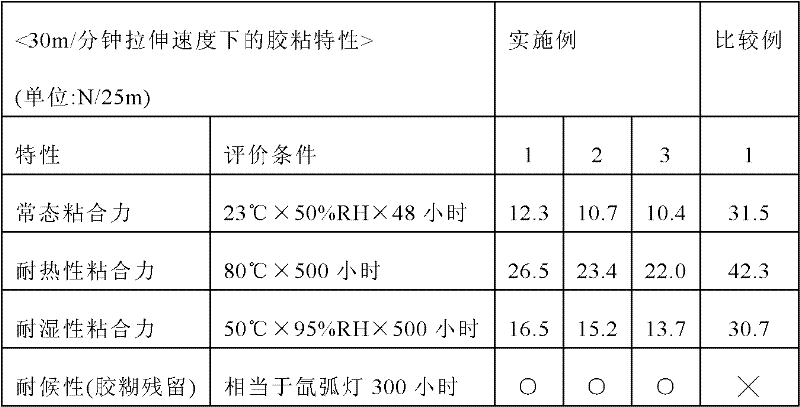

Embodiment 1

[0112] (Preparation of (meth)acrylic polymer)

[0113] In a four-necked flask with a stirring blade, a thermometer, a nitrogen introduction tube, and a condenser, 30 parts by weight of 2-ethylhexyl acrylate, 70 parts by weight of ethyl acrylate, 5 parts by weight of methyl methacrylate, 4 parts by weight of parts by weight of 2-hydroxyethyl acrylate, 0.2 parts by weight of 2,2'-azobisisobutyronitrile as a polymerization initiator, and 200 parts by weight of ethyl acetate, introduce nitrogen gas while stirring slowly, and keep the liquid temperature in the flask A (meth)acrylic polymer solution (35% by weight) was prepared by carrying out a polymerization reaction at about 65°C for about 6 hours. The glass transition temperature (Tg) of the (meth)acrylic polymer was -29°C.

[0114] (Preparation of binder solution)

[0115] The (meth)acrylic polymer solution (35 wt %) was diluted to 20 wt % with ethyl acetate, and 0.6 wt. Parts of isocyanate-based compound (Corotate L, manufa...

Embodiment 2

[0119] An automobile was produced in the same manner as in Example 1, except that the (meth)acrylic pressure-sensitive adhesive solution (B) obtained by blending 0.8 parts by weight of the isocyanate-based compound (Corotate L, manufactured by Nippon Polyurethane Industry Co., Ltd.) was used. Protective film for wheels.

Embodiment 3

[0121] An automobile was produced in the same manner as in Example 1, except that a (meth)acrylic pressure-sensitive adhesive solution (C) obtained by blending 1.0 parts by weight of the isocyanate-based compound (Corotate L, manufactured by Nippon Polyurethane Industry Co., Ltd.) was used. Protective film for wheels.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com