Double-layer steel-truss concrete laminated arch structure and construction method thereof

A technology of concrete structure and arch structure, which is applied to arch bridges, bridge parts, erection/assembly bridges, etc. It can solve the problems of long construction period, self-heavy arch ribs, and difficult construction, and achieve the effect of simple and reasonable structural stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

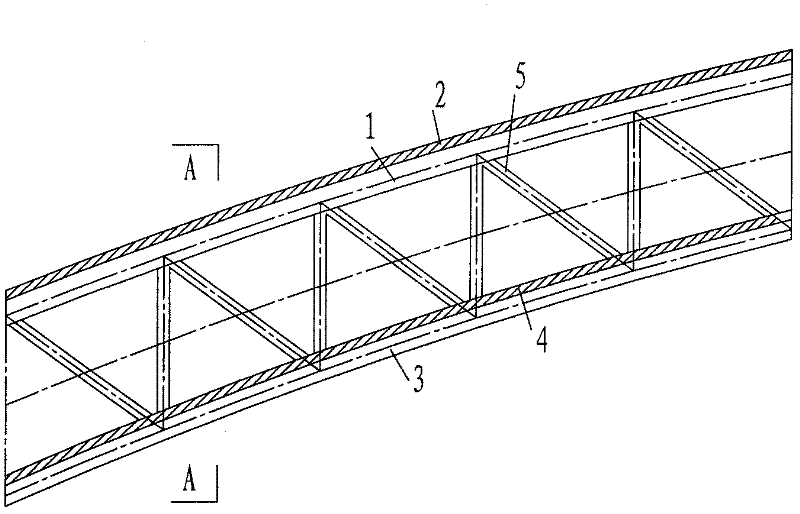

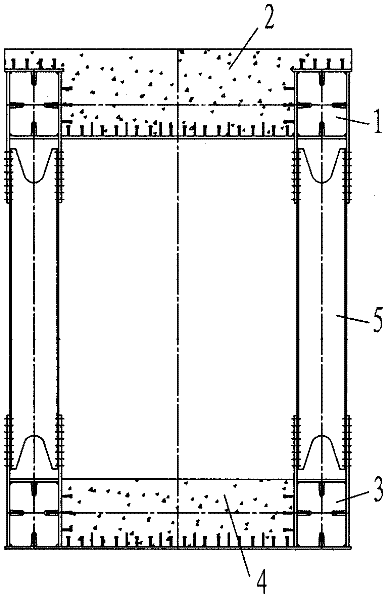

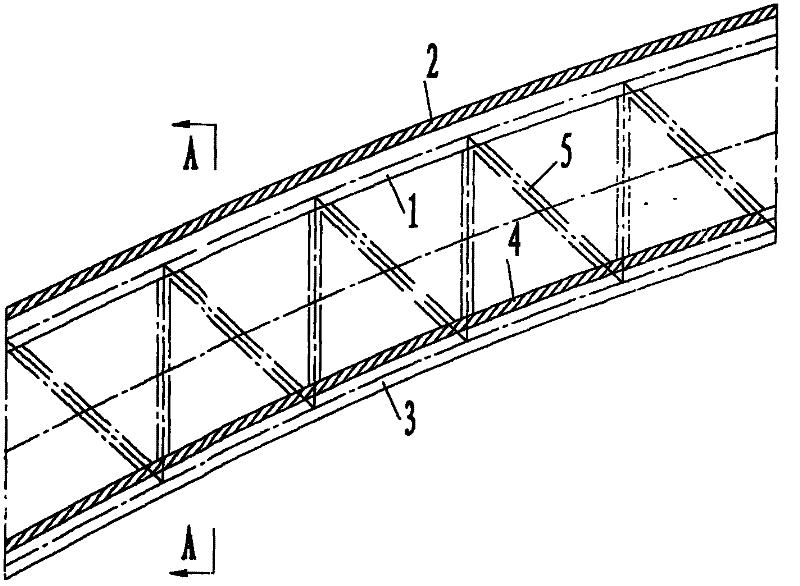

[0017] refer to figure 1 , 2 , the double-layer steel truss concrete composite arch structure of the present invention is to have an upper steel structure 1 and an upper concrete structure 2 above the steel truss arch formed by steel webs, rods 5 and steel chords, and a lower steel structure below 3 and the lower concrete structure 4.

[0018] For the construction method of the double-layer steel truss concrete composite arch structure, the specific steps for the arch form cast on site are as follows:

[0019] 1) Steel webs, rods 5 and steel chords are used to form a steel truss arch, and the steel truss arch structure is not only a part of the permanent structure, but also a formwork for the post-cast concrete structure;

[0020] 2) Concrete is poured on the upper and lower floors of the steel truss arch structure respectively to form a double-layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com