Large-area zinc electrolysis anode plate production line

An anode plate, zinc electrolysis technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of heavy workload of operators, low time efficiency of cell electrolysis, difficult management, etc., to prolong electrolysis time and high production efficiency , the overall layout of the compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

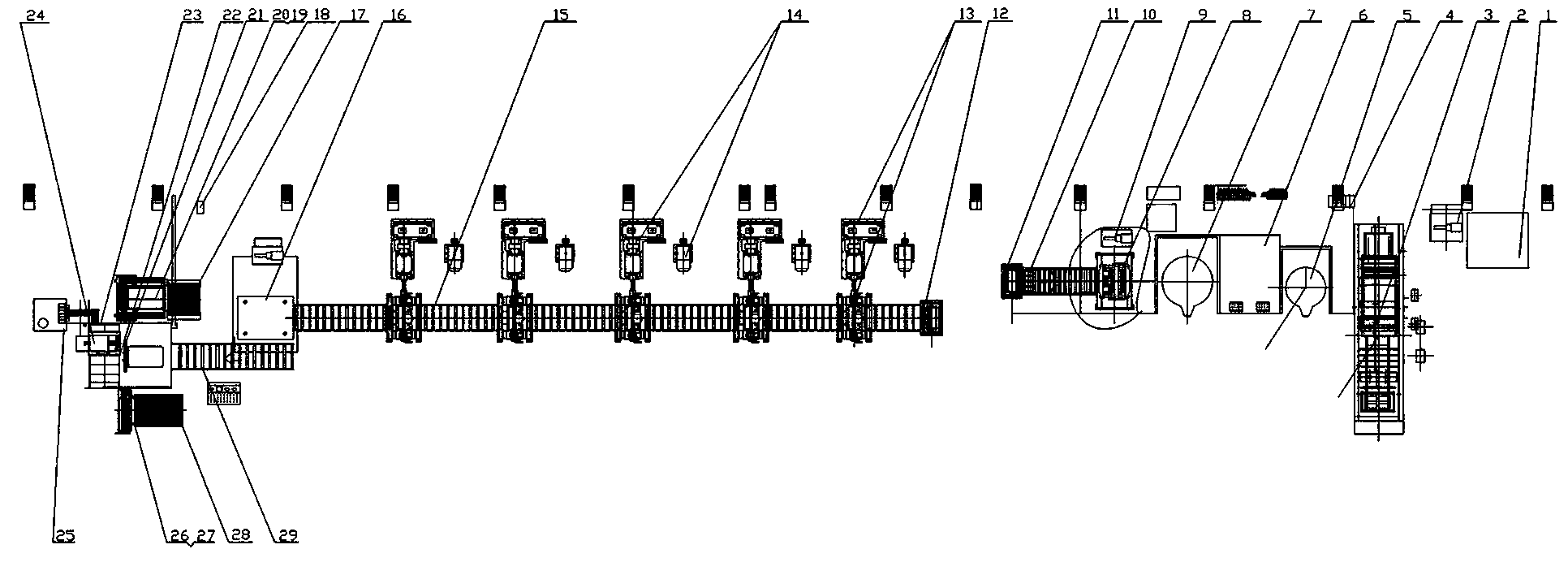

[0019] A 3.2-square-meter zinc electrolysis anode plate production line, the invention is characterized in that it is composed of a casting system, a rolling mill system, a punching blanking system and a friction stir welding system connected in sequence, and its technological process is: casting system→rolling mill system→punching Hole blanking system → friction stir welding system.

[0020] in:

[0021] a. Casting system:

[0022] 1 The anode plate conductive beam casting system includes: beam casting unit 4, 6t power frequency electric furnace 5, casting platform 6, of which beam casting unit 4 includes transportation device, conductive copper rod heating, pickling, drying, tin hanging device and frame ;

[0023] 2. The casting system for anode rough slabs includes: 10t industrial frequency electric furnace 7, vertical slab casting machine 8, roller conveying mechanism 10, and stacking mechanism 11; the vertical slab casting machine 8 is also connected to the slab casting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com