Method for processing black dried bamboo and a method for processing flexible package of black bamboo

A processing method and flexible packaging technology, which is applied in the field of bamboo shoot processing, can solve the problems of unsafe eating, destructive nutrition, high sulfur content, etc., and achieve the effects of maintaining taste and nutrition, increasing roasted fragrance, and delicious taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

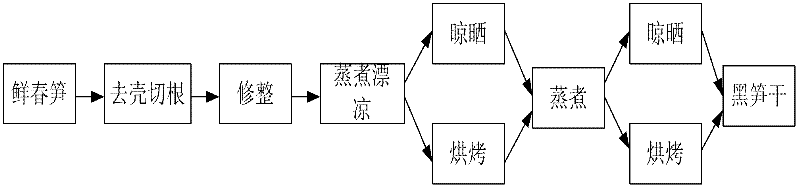

[0037] Please also refer to figure 1 , as shown in the figure, the dried black bamboo shoot processing method embodiment of the present invention includes pretreatment, cooking, blanching and drying processes, and the specific steps are as follows:

[0038] 1. Digging bamboo shoots: Start digging bamboo shoots around Qingming. When digging bamboo shoots, you should peel the shells and remove the roots while digging.

[0039] 2. Cut the bamboo shoots: When the fresh bamboo shoots are delivered, they should be piled on the bamboo mat, and then the roots should be scraped flat with the back of a knife. The smoother the better. If there is sludge, it must be washed.

[0040] 3. Boil bamboo shoots: wash the pot, then add water to add 2-5% longan shells, 0.1-0.3% laurel leaves, 0.1-0.2% grass fruit, add 0.3-1% straw ash to boil, put fresh bamboo shoots in the pot The fresh bamboo shoots inside must be stuffed tightly, cover them and cook for 2-3 hours over high heat.

[0041] 4. ...

Embodiment 2

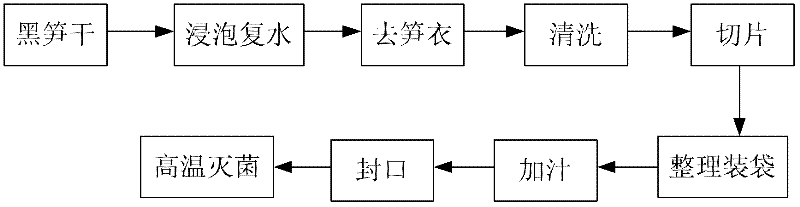

[0046] Please also refer to figure 2 , as shown in the figure, the processing method of black bamboo shoot flexible packaging of the present invention is improved on the basis of embodiment 1, comprises pretreatment, steaming and blanching and drying process, and concrete steps are as follows:

[0047] 1. Raw material

[0048] Choose no borers, no rot, dark brown in color, and 14-27cm long black bamboo shoots as raw materials. Cut off the aged or lignified parts, and keep the bamboo shoot tips well.

[0049] 2. Soaking, rehydration, washing and shaving

[0050] It usually takes 3-4 days for dried black bamboo shoots to be soaked in the pool, which is slightly longer in winter and shorter in summer. It is required to change the soaking water frequently, especially in summer, it is required to change 1-2 times a day. Remove the bamboo shoots and old parts while washing.

[0051] 3. Slicing

[0052] The soaked dried bamboo shoots are cut into slices by hand or by machine, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com