Shrimp meat quality improver as well as preparation method and application thereof

A technology of quality improver and shrimp meat, which is applied in the field of shrimp meat quality improver and its preparation, can solve the problems of lack of umami taste, high price, fragrance, taste, and poor elasticity, so as to improve the flavor and taste and improve the quality of shrimp. The effect of meat quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

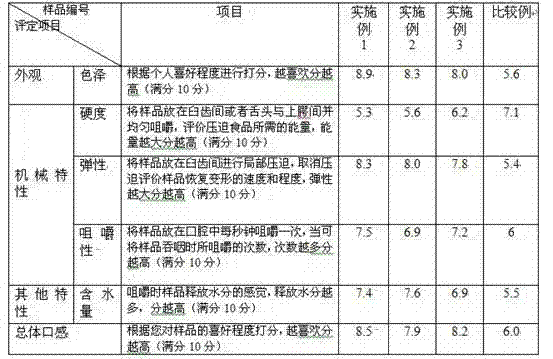

Embodiment 1

[0021] Take about 1000g of shrimp and thaw at 0-10°C.

[0022] Weigh 12g of sodium bicarbonate, 20g of sodium citrate, 10g of potassium chloride, 30g of potassium gluconate, 10g of sodium carbonate, 12g of sodium phosphate, and 12g of potassium phosphate, add about 1500ml of water to make a solution, stir well, add 20g of table salt, Stir until dissolved, then measure the pH value, add glycine, adjust the pH value to 7.5, then weigh 1.5g of transglutaminase, add it to the solution with the adjusted pH value, stir well, and soak the thawed shrimp Put it into the prepared solution, soak for 10 hours, then fish out the shrimp, place it at -80°C for quick freezing, and transfer it to -20°C for frozen storage after quick freezing for 4 hours.

[0023] The preserved shrimps were thawed and boiled in boiling water for two minutes before sensory evaluation.

Embodiment 2

[0025] Take about 1000g of shrimp and thaw at 0-10°C.

[0026] Weigh 12g of sodium bicarbonate, 20g of sodium citrate, 10g of potassium chloride, 30g of potassium gluconate, 10g of sodium carbonate, 12g of sodium phosphate, and 12g of potassium phosphate, add about 1500ml of water to make a solution, stir well, add 20g of table salt, Stir until dissolved, then measure the pH value, add glycine, adjust the pH value to 8.5, then weigh 1.5g of transglutaminase, add it to the above-mentioned solution whose pH value has been adjusted, stir well, and soak the thawed shrimp Put it into the prepared solution, soak for 10 hours, then fish out the shrimp, place it at -80°C for quick freezing, and transfer it to -20°C for frozen storage after quick freezing for 4 hours.

[0027] The preserved shrimps were thawed and boiled in boiling water for two minutes before sensory evaluation.

Embodiment 3

[0029] Take about 1000g of shrimp and thaw at 0-10°C.

[0030] Weigh 12g of sodium bicarbonate, 20g of sodium citrate, 10g of potassium chloride, 30g of potassium gluconate, 10g of sodium carbonate, 12g of sodium phosphate, and 12g of potassium phosphate, add about 1500ml of water to make a solution, stir well, add 20g of table salt, Stir until dissolved, then measure the pH value, add glycine, adjust the pH value to 7.5, then weigh 1.0 g of transglutaminase, add it to the above-mentioned solution whose pH value has been adjusted, stir well, and soak the thawed shrimp Put it into the prepared solution, soak for 10 hours, then fish out the shrimp, place it at -80°C for quick freezing, and transfer it to -20°C for frozen storage after quick freezing for 4 hours.

[0031] The preserved shrimps were thawed and boiled in boiling water for two minutes before sensory evaluation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com