Feed additive for dairy cow and preparation method thereof

A dairy cow feed and production method technology, applied in animal feed, animal feed, application, etc., can solve the problems of imbalanced amino acid composition, affecting milk protein synthesis, and low efficiency of rumen microbial protein synthesis, so as to increase utilization efficiency and make up energy Effects of negative balance and loss of body condition, increased daily milk production and peak persistence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

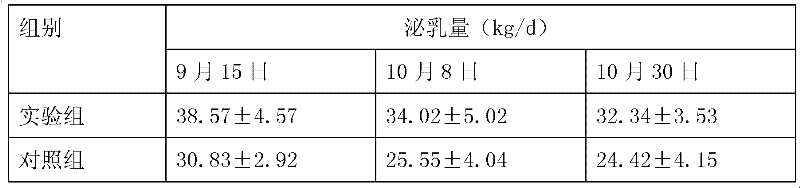

Examples

example 1

[0035] Example 1: A dairy cattle feed additive consists of the following ingredients:

[0036] Schizophyllum 22wt%, Ganoderma lucidum 15wt%, Sustained release agent 4wt%; Puffed soybean: 45wt%, Urea 6wt%: Soybean polypeptide powder: 5wt%; Aspergillus awamori culture 3wt%

[0037] The schizophyllum is a schizophyllum fruiting body;

[0038] The ganoderma is ganoderma fermented mycelia;

[0039] The sustained-release agent is mainly composed of ferrous sulfate, copper sulfate, calcium carbonate, sodium metabisulfite:

[0040] The composition ratio of the sustained-release agent is as follows according to weight percentage: 10% of ferrous sulfate, 15% of copper sulfate, 70% of calcium carbonate, and 5% of sodium metabisulfite;

[0041] The preparation method is as follows:

[0042] Sustained-release agent pretreatment: the calcium carbonate component in the sustained-release agent is pulverized and mixed evenly with other sustained-release agent components;

[0043] Grinding ...

example 2

[0051] Example 2 The dairy cow feed additive consists of the following ingredients:

[0052] Schizophyllum 35wt%, Ganoderma lucidum 10wt%, Sustained release agent 3wt%; Puffed soybean: 30wt%, Urea 9wt%: Soybean polypeptide powder: 8wt%, Aspergillus awamori culture 5wt%

[0053] The schizophyllum is a schizophyllum fruiting body;

[0054] The ganoderma is a fruiting body;

[0055] The sustained-release agent is mainly composed of ferrous sulfate, copper sulfate, calcium carbonate, sodium metabisulfite:

[0056] The composition ratio of the sustained-release agent is as follows according to weight percentage: 5% of ferrous sulfate, 10% of copper sulfate, 80% of calcium carbonate, and 5% of sodium metabisulfite.

[0057] The preparation method is basically the same as Example 1

example 3

[0059] The invention provides a dairy cattle feed additive,

[0060] Product of the present invention is made up of following composition:

[0061] Schizophyllum 27wt%, Ganoderma lucidum 10wt%, slow-release agent 3wt%; puffed soybean: 45wt%, urea 4wt%; soybean polypeptide powder: 6wt%, Aspergillus awamori culture 5wt%;

[0062] The schizophyllum is the fermented mycelium of the schizophyllum;

[0063] The ganoderma is a fruiting body;

[0064] The sustained-release agent is mainly composed of ferrous sulfate, copper sulfate, calcium carbonate, sodium metabisulfite:

[0065] The composition ratio of the sustained-release agent is as follows according to weight percentage: 15% of ferrous sulfate, 15% of copper sulfate, 60% of calcium carbonate, and 10% of sodium metabisulfite;

[0066] The preparation method is basically the same as Example 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com