Pixel structure, active element array substrate and planar display panel

A technology of pixel structure and active components, which is applied in the direction of electrical components, electric solid devices, semiconductor devices, etc., can solve the problems of reducing the available area of storage capacitors, failing to increase storage capacitors, and changes in parasitic capacitance values, so as to improve the quality of screen display, Reduce asymmetrical gate-drain capacitance and increase the effect of storage capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

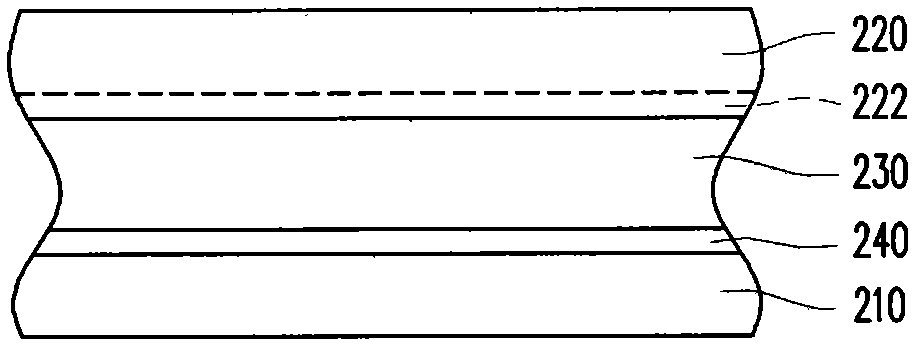

[0061] figure 2 is a schematic cross-sectional view of a flat display panel according to an embodiment of the present invention. Please refer to figure 2 , the flat display panel includes a first substrate 210 , a second substrate 220 , a display medium 230 and an active device array 240 . The second substrate 220 is disposed above the first substrate 210 . The second substrate 220 may be a simple blank substrate or a substrate further including the opposite electrode 222 . The display medium 230 is disposed between the first substrate 210 and the second substrate 220 . The display medium 230 is, for example, an electrophoretic display film, an organic electroluminescence layer or a liquid crystal layer, wherein the electrophoretic display film can be a microcapsule electrophoretic display film or a microcup electrophoretic display film, which is known to those skilled in the art are well known, so no further details are given. The active device array 240 is disposed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com