Superconducting heat-absorbing piece

A heat-absorbing sheet and superconducting technology, applied in the field of solar energy, can solve the problem that the superiority of flat-panel solar collectors cannot be better displayed, the heat exchange efficiency between the flow channel and the water tank is not high, and the heat absorption of the heat-absorbing plate core is reduced, etc. problems, to achieve the effect of simple assembly, simple structure, and improved thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

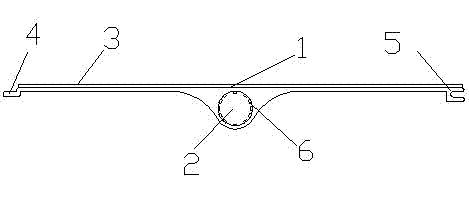

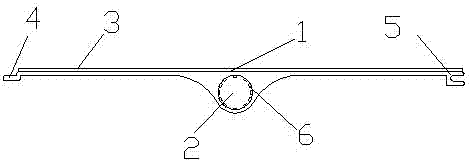

[0013] Embodiment 1: as figure 1 As shown, this embodiment is composed of an aluminum substrate 1, a superconducting flow channel 2, and a selective heat-absorbing coating 3. The aluminum substrate 1 and the superconducting flow channel 2 are integrated, and are integrally extruded by a mold. The material is 3003 Anti-rust aluminum with selective absorbing coating 3 on the front and superconducting flow channel 2 on the back. The number of superconducting channels 2 of each superconducting heat-absorbing sheet is calculated and set according to the heat-absorbing area and heat transfer efficiency. In this embodiment, one superconducting channel 2 is provided.

[0014] A superconducting medium is arranged in the superconducting flow channel 2 , and a return groove 6 is arranged in the superconducting flow channel 2 . The two edges of the aluminum substrate 1 are respectively provided with a male card slot 4 and a female card slot 5 , and different superconducting heat absorbin...

Embodiment 2

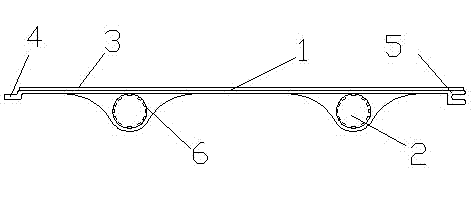

[0016] Embodiment 2: as figure 2 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that two groups of superconducting channels 2 are provided in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com