Light emitting diode (LED) secondary optical lens

A technology of secondary optical lens and total reflection surface, applied in the direction of light source, point light source, lighting device, etc., can solve the problems of luminous flux attenuation, affecting LED lighting performance, etc., to achieve high uniformity, high effective light energy utilization, The effect of curbing glare

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to further understand the features, technical means, specific objectives and functions achieved by the present invention, and to analyze the advantages and spirit of the present invention, a further understanding of the present invention can be obtained through the following detailed description of the present invention in conjunction with the accompanying drawings and specific embodiments.

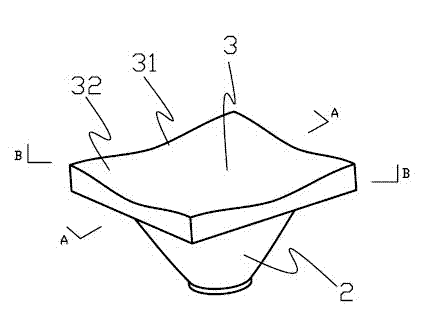

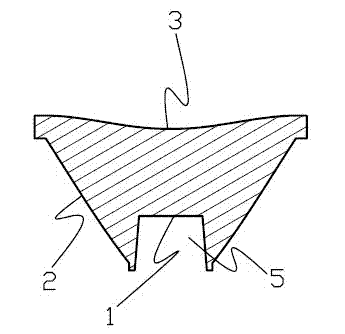

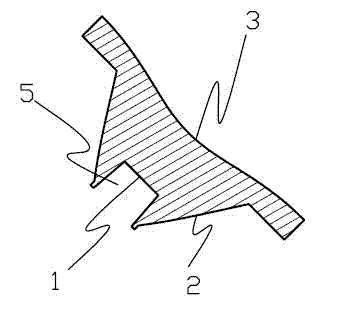

[0041] As shown in the drawings of the description, the present invention includes an incident surface 1, a total reflection surface 2 and an exit surface 3, and the bottom of the total reflection surface 2 is provided with an LED light source groove 5, and the LED light source groove 5 is used to place an LED light source 4 . The exit surface 3 is a cross-shaped curved surface, and the cross-shaped curved surface is composed of a concave surface 31 with the same smooth transition structure in the horizontal direction and a vertical direction and a convex surface 32 with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com