Large-specification and high-strength D40 hot-rolled flat-bulb steel for ships and production process for hot-rolled flat-bulb steel

A production process and technology for flat bulb steel, which are applied in the field of large-size and high-strength D40 marine hot-rolled flat bulb steel and its production process, to achieve the effects of simple operation process and improved safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

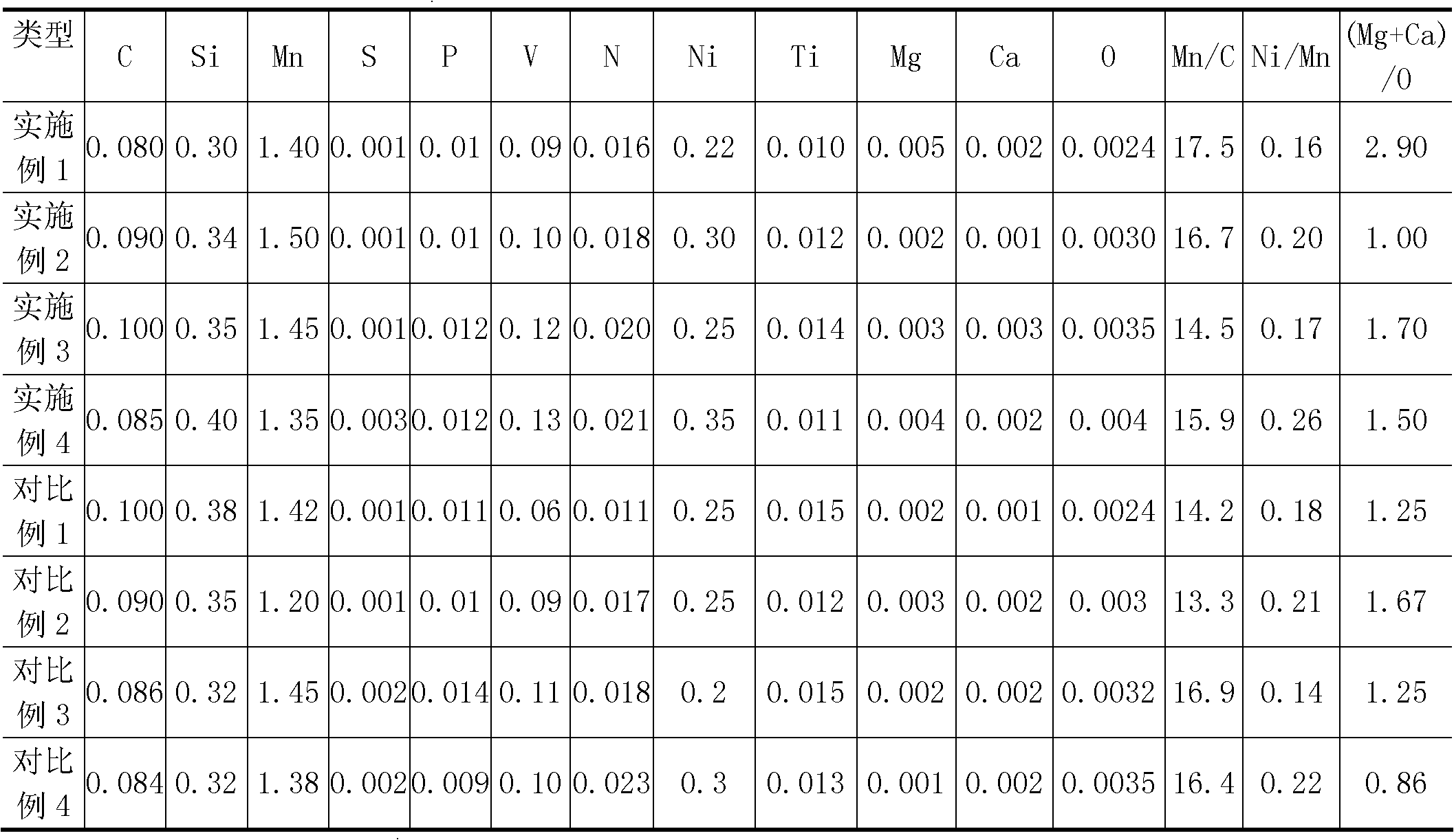

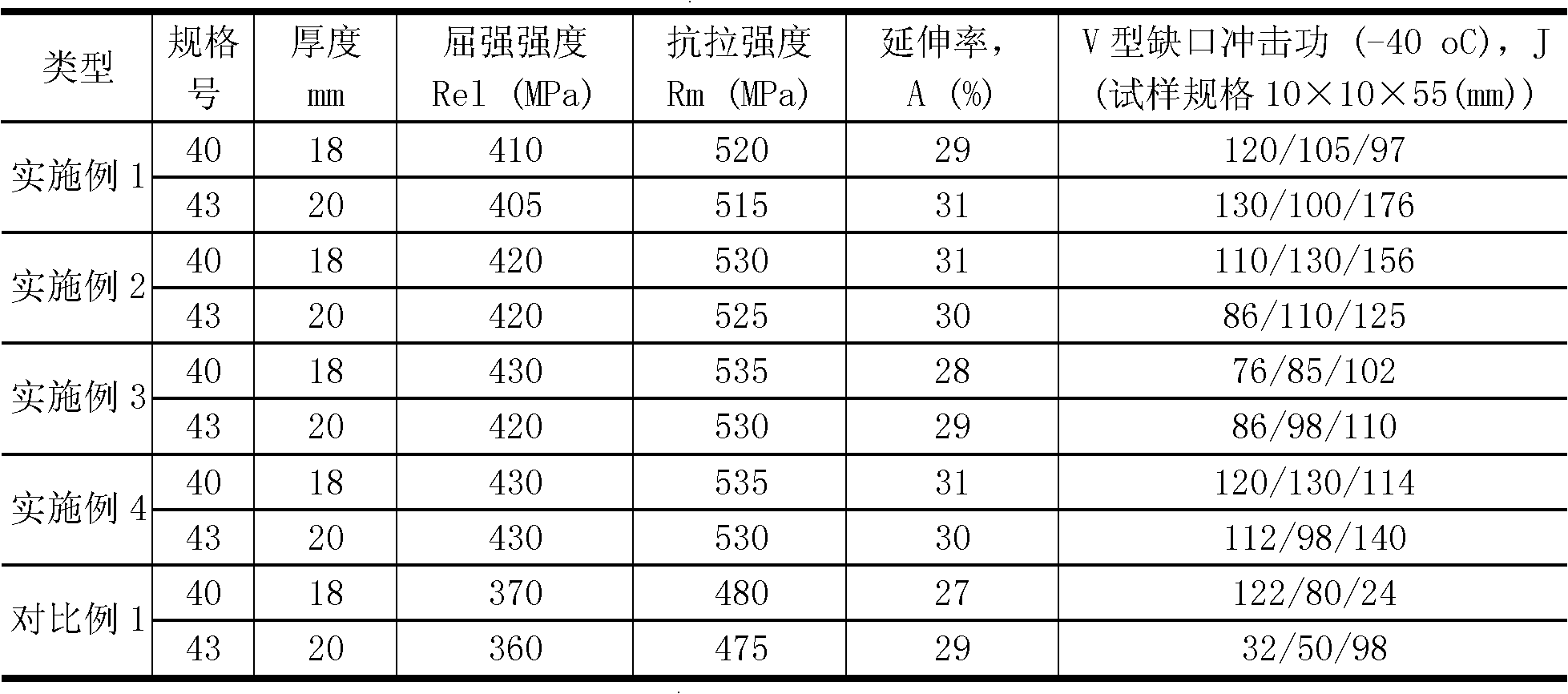

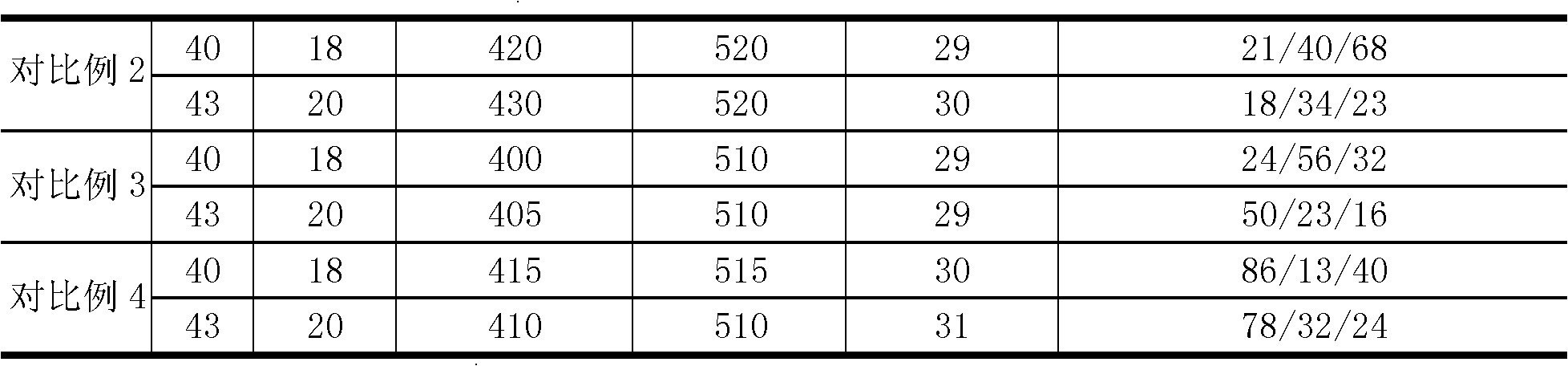

[0031] The present invention will be described below by comparing different examples and comparative examples. These examples are for explanatory purposes only, and the present invention is not limited to these examples.

[0032] Table 1 shows the chemical composition of various flat bulb steels in the examples and comparative examples, wherein there are 4 kinds of steels in the examples and 4 kinds of steels in the comparative examples. These bulbous flat steels are smelted in a 100-ton converter. After smelting, continuous casting, and rolling processes, they are prepared into No. 40 and No. 43 steel types with web thicknesses of 18mm and 20mm. The following process points are followed for smelting and continuous casting control:

[0033] 1) Adopt LF+RH steelmaking process. After RH is finished, feed vanadium-nitrogen alloy wire with a diameter of 12mm, blow argon and stir for 3 minutes; then feed Mg-Ca alloy wire with a diameter of 10mm, blow argon and stir for 5 minutes. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com