Method for preparing bitter almond extract product

A kind of bitter almond and extract technology, which is applied in the field of preparing bitter almond extract, can solve the problems of denaturation of bitter almond protein, influence the deep development and utilization of bitter almond protein, etc., and achieve the effect of preventing excessive denaturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

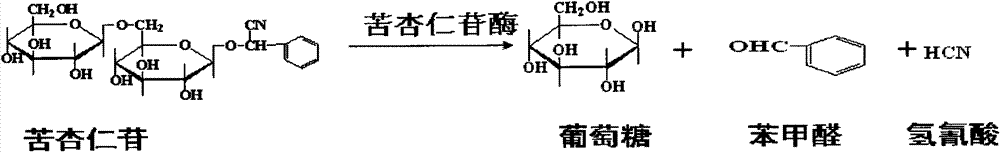

Method used

Image

Examples

Embodiment 1

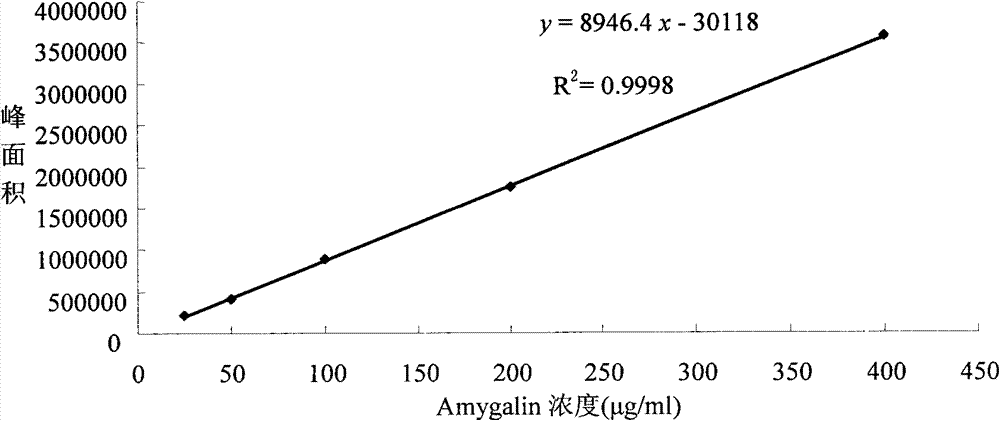

[0030] 1) 100 g of bitter almonds are dried in the sun, so that the water activity of the bitter almonds is 0.70, and the dried bitter almonds are obtained;

[0031] According to the Soxhlet extraction method, the bitter almond oil in the bitter almond as the raw material is determined, and the amygdalin in the bitter almond as the raw material is determined by high performance liquid chromatography, and the amygdalin as the raw material is determined according to the Kjeldahl method. The protein in the bitter almond is measured, as can be known, wherein the mass percentage composition of oil, amygdalin and protein is respectively 45.8%, 3.25% and 22.6%;

[0032] 2) Under the condition that the water activity of the dried bitter almonds obtained in step 1) is kept at 0.70, the dried bitter almonds are pulverized to 10 meshes to obtain 96.8 g of pulverized bitter almonds;

[0033] 3) Under the condition that the water activity of the pulverized bitter almonds obtained in step 2...

Embodiment 2

[0044] 1) 100 g of bitter almonds are dehydrated with 20 mL of dehydrating agent ethanol, so that the water activity of bitter almonds is 0.53, and dried bitter almonds are obtained;

[0045]According to the Soxhlet extraction method, the bitter almond oil in the bitter almond as the raw material is determined, and the amygdalin in the bitter almond as the raw material is determined by high performance liquid chromatography, and the amygdalin as the raw material is determined according to the Kjeldahl method. The protein in the bitter almond is measured, as can be known, wherein the mass percentage composition of oil, amygdalin and protein is respectively 45.8%, 3.25% and 22.6%;

[0046] 2) Under the condition that the water activity of the dried bitter almonds obtained in step 1) is kept at 0.53, the dried bitter almonds are pulverized to 120 mesh to obtain 94.52 g of pulverized bitter almonds;

[0047] 3) under the condition that the water activity of the bitter almonds afte...

Embodiment 3

[0058] 1) Dry 100 g of bitter almonds by freeze-drying, so that the water activity of bitter almonds is 0.40, and obtain dried bitter almonds; in this freeze-drying step, first pre-freeze the material to -40°C, and then turn on the vacuum pump , so that the vacuum degree is 20-40Pa to carry out the vacuum freeze-drying operation, and the freeze-drying is completed when the material temperature is close to room temperature.

[0059] According to the Soxhlet extraction method, the bitter almond oil in the bitter almond as the raw material is determined, and the amygdalin in the bitter almond as the raw material is determined by high performance liquid chromatography, and the amygdalin as the raw material is determined according to the Kjeldahl method. The protein in the bitter almond is measured, as can be known, wherein the mass percentage composition of oil, amygdalin and protein is respectively 45.8%, 3.25% and 22.6%;

[0060] 2) Under the condition that the water activity of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

| peroxide value | aaaaa | aaaaa |

| peroxide value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com