Adaptive control method for current loop of magnetic levitation system

An adaptive control and magnetic levitation technology, which is applied in the direction of adaptive control, general control system, control/adjustment system, etc., can solve the problems affecting the overall performance of the magnetic levitation system, affecting the current loop current rise time and gain, etc., to overcome the levitation system Unstable performance, stable and reliable suspension performance, simple and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

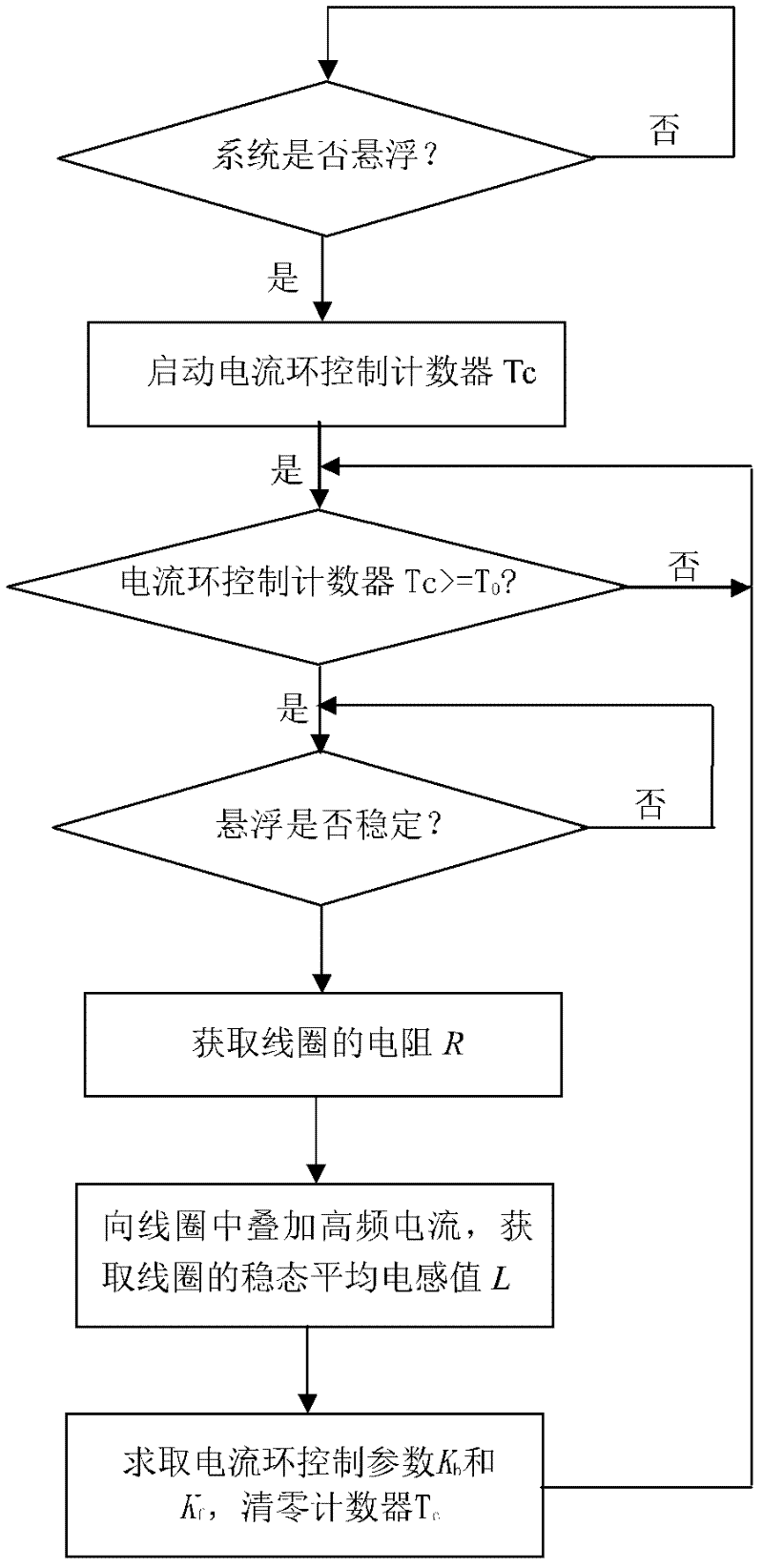

[0030] Such as image 3 As shown, the implementation steps of the current loop adaptive control method of the magnetic levitation system in the embodiment of the present invention are as follows:

[0031] 1) After the maglev system is levitated, judge whether the maglev system is stable or not;

[0032] 2) If the suspension is stable, then collect the suspension stabilization current I and the suspension stabilization voltage U of the magnetic levitation system coil, and obtain the suspension stabilization resistance R of the coil according to the suspension stabilization current I and the suspension stabilization voltage U in combination with R=U / I;

[0033] 3) Superimpose the high-frequency current that does not change the levitation gap of the magnetic levitation system to the coil, and collect the current I of the coil multiple times during the coil current change process i (i=1, 2, 3...) and voltage U i (i=1, 2, 3...), according to the current I collected by the coil du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com