Cast copper water jacket embedded with double-layer pure copper pipes and manufacturing method thereof

A manufacturing method and technology for copper pipes are applied in the field of buried double-layer pure copper pipes and cast copper water jackets, which can solve problems such as large influence on production and operation, and achieve the effects of eliminating hidden dangers in use, reducing water flow, and high leak-proof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

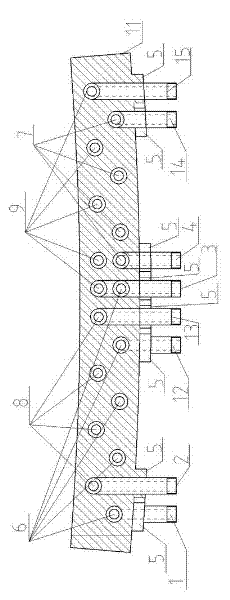

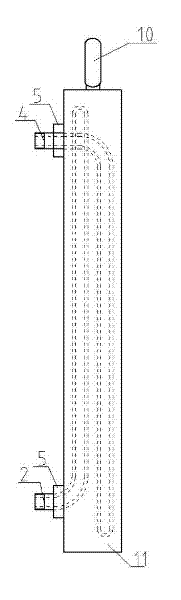

[0030] First, four cooling pipes 6, 7, 8, and 9?49×6 whole hot-extruded pure copper pipes are bent into shape. The bent copper tube is pickled to remove rust and polished, and then the inner cavity of the copper tube is filled with resin sand and a certain proportion of phenolic resin. The weight ratio between resin sand and phenolic resin is 100:0.6. The pretreated copper pipe is installed with a pipe clamp positioning device and pre-embedded in the graphite mold, and a feeding channel and a stepped pouring system are set in the mold. Then push the molded box into the drying room and quickly raise the temperature to 540°C for 4 hours, then leave the drying room and lower the temperature to 100°C, and pour the smelted copper water containing Cu≥99.95% into the mold box through the pouring system, and the copper water The furnace temperature is controlled at 1228°C, and the pouring temperature is controlled at 1130°C; when the temperature drops to 700°C, the casting is opened a...

Embodiment 2

[0032]First, four cooling pipes 6, 7, 8, and 9?49×6 whole hot-extruded pure copper pipes are bent into shape. The bent copper tube is pickled to remove rust and polished, and then the inner cavity of the copper tube is filled with resin sand and a certain proportion of phenolic resin. The weight ratio between resin sand and phenolic resin is 100:0.8. The pretreated copper pipe is installed with a pipe clamp positioning device and pre-embedded in the graphite mold, and a feeding channel and a stepped pouring system are set in the mold. Then push the molded box into the drying room and quickly raise the temperature to 550°C for 4 hours, then leave the drying room and lower the temperature to 110°C, and pour the smelted copper water containing Cu≥99.95% into the mold box through the pouring system, and the copper water The furnace temperature is controlled at 1242°C, and the pouring temperature is controlled at 1148°C; when the temperature drops to 750°C, the casting is opened an...

Embodiment 3

[0034] First, four cooling pipes 6, 7, 8, and 9?49×6 whole hot-extruded pure copper pipes are bent into shape. The bent copper tube is pickled to remove rust and polished, and then the inner cavity of the copper tube is filled with resin sand and a certain proportion of phenolic resin. The weight ratio between resin sand and phenolic resin is 100:0.7. The pretreated copper pipe is installed with a pipe clamp positioning device and pre-embedded in the graphite mold, and a feeding channel and a stepped pouring system are set in the mold. Then push the molded box into the drying room and quickly raise the temperature to 530°C for 4 hours, then leave the drying room and lower the temperature to 90°C, and pour the smelted copper water containing Cu≥99.95% into the mold box through the pouring system, and the copper water The furnace temperature is controlled at 1225°C, and the pouring temperature is controlled at 1125°C; when the temperature drops to 700°C, the casting is opened an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com