Oil nozzle of diesel engine

A technology of fuel injectors and diesel engines, applied in mechanical equipment, engine components, machines/engines, etc., can solve serious problems, energy waste, oil dripping, etc., and achieve the effect of improving efficiency and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

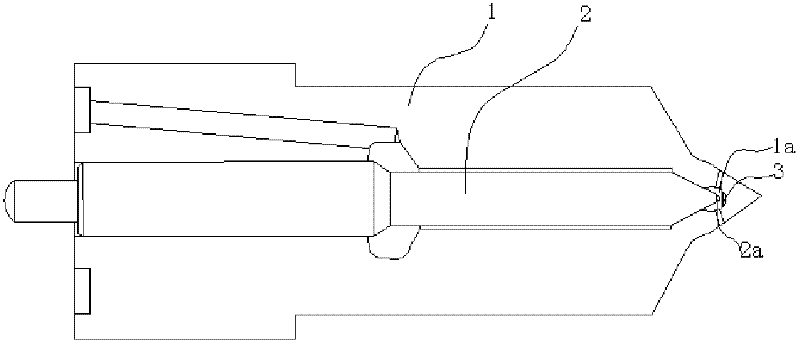

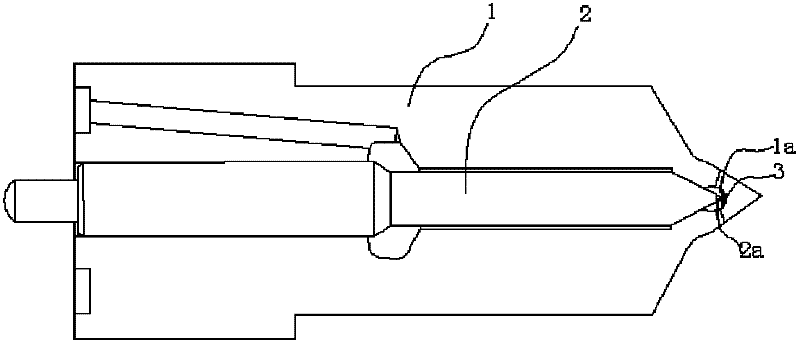

[0012] Such as figure 1 , figure 2 As shown, a fuel injector for a diesel engine includes a needle valve body 1 and a needle valve 2 arranged in the needle valve body 1, wherein the needle valve body 1 includes a pressure chamber 1a, and the pressure chamber 1a is oval in shape, and on the front of the needle valve 2 A baffle 3 is provided in the pressure chamber 1a, and the baffle 3 divides the pressure chamber 1a into a lower pressure chamber and a pressure chamber cavity. The section of the head of the needle valve 2 is frustum-shaped, and a spherical Protrusion 2a, the lower pressure chamber communicates with the oil outlet passage of needle valve body 1.

[0013] Wherein, the ratio of the diameter of the frustum of the cone to the diameter of the spherical protrusion is 4:3.

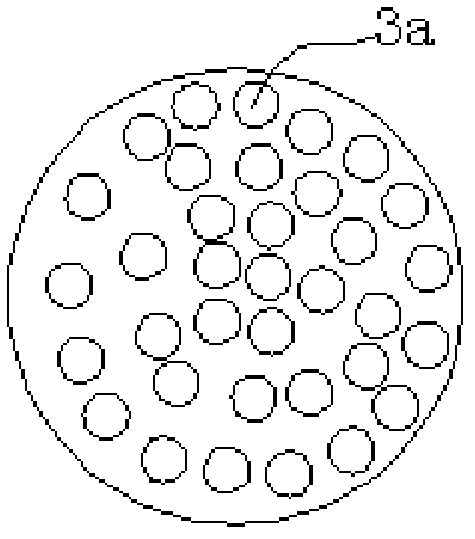

[0014] Wherein, the surface of the separator 3 is rough and provided with evenly distributed pits 3a.

[0015] Wherein, the end of the needle valve body 1 is tapered.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com