Material-saving heat-resisting antifriction self-lubricating material

A self-lubricating material, heat-resistant technology, applied in the manufacture of tribological parts and components that serve in a wide temperature range environment, the field of material-saving heat-resistant friction-reducing self-lubricating materials, can solve problems such as quality defects, and achieve the goal of using Long life, stable high temperature strength, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

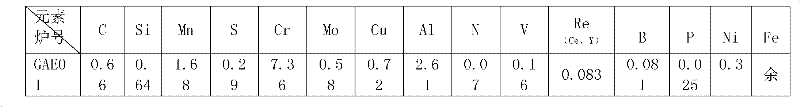

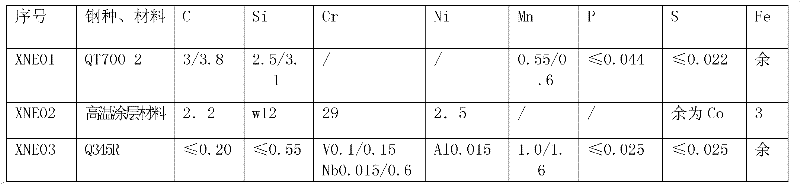

[0035] Example 1: According to the chemical composition of the material designed in the present invention, three kinds of wear-resistant, anti-friction, stainless and self-lubricating new materials were prepared. , and carried out experiments and comparisons according to the existing materials used for different purposes on site. The specific chemical composition of GAE01 material is shown in Table 1. The compressive strength of the material is 1450MPa at 20°C, 665MPa at 500°C, the hardness at room temperature is HRc56, and the friction coefficient is 0.12 at 20°C and 0.25 at 500°C. This material is used to produce pinch rolls for metallurgical strip steel and compared with the original material QT700 (see Table 2 XNE01 for the specific chemical composition), its service conditions and performance are shown in Table 3.

Embodiment 2

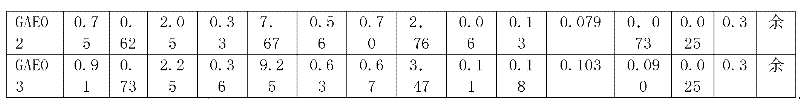

[0036] Example 2: See Table 1 for the specific chemical composition of the GAE02 material. The compressive strength of the material is 1580MPa at 20°C, 720MPa at 500°C, the hardness at room temperature is HRc60, and the friction coefficient is 0.15 at 20°C and 0.22 at 500°C. This material is used in chemical fiber production to compare the surface of the stirring rotor blade with the original imported high-temperature coating material (see Table 2 XNE02 for specific chemical composition), and the use conditions and performance are shown in Table 3.

Embodiment 3

[0037] Example 3: The specific chemical composition of the GAE03 material is shown in Table 1. The compressive strength of the material is 1630MPa at 20°C, 730MPa at 500°C, the hardness at room temperature is HRc60, and the friction coefficient is 0.17 at 20°C and 0.24 at 500°C. This material is used in the metallurgical coil production crimping device to compare with the original material Q345R (see Table 2 XNE03 for the specific chemical composition), and its service conditions and properties are shown in Table 3.

[0038] The chemical composition table (mass %) of the embodiment of the present invention of table 1

[0039]

[0040]

[0041] Note: Ni<0.30 in the smelting composition is the residual amount, and the control P<0.025.

[0042] Table 2 main chemical composition list of materials in the prior art

[0043]

[0044] The parts and components prepared by the embodiment of the present invention are compared with the industrial field performance of the parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Room temperature hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com