Polypropylene (PP) alloy material with low molding shrinkage and preparation method thereof

An alloy material, polypropylene technology, applied in the field of polypropylene alloy material and its preparation, can solve rare problems, achieve the effects of improving tensile strength, realizing general plastic engineering, and excellent surface gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

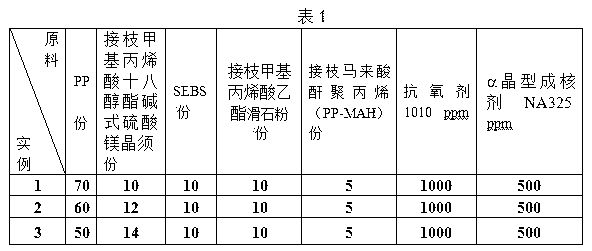

[0039] The concrete preparation formula of polypropylene alloy material of the present invention is as shown in table 1, and implementation steps are as follows:

[0040] The SEBS product is crushed into SEBS powder, and the impact copolymerized polypropylene resin EPC30R-H is crushed into powder.

[0041] 10 parts of SEBS powder, 70 parts of impact copolymer polypropylene resin EPC30R-H, 5 parts of compatibilizer grafted maleic anhydride polypropylene (PP-MAH), grafted stearyl methacrylate basic magnesium sulfate 10 parts of whiskers, 10 parts of grafted ethyl methacrylate talcum powder, 1000ppm antioxidant 1010, 500ppm a crystal nucleating agent NA325 placed in a high-speed blender and mixed for 10 minutes before adding to the twin-screw extruder Carry out extruding, pelletizing, the aspect ratio of the 5 section mixing elements of this twin-screw extruder is 35 : 1. The diameter of the screw is 35.6 mm, and the main engine speed of the twin-screw extruder is 150 rpm, the f...

Embodiment 2

[0044] According to Example 1 similar to the formulation Example 2, the difference is that the amount of PP is 60 parts, and the grafted stearyl methacrylate basic magnesium sulfate whisker is 12 parts, and the low-mode is prepared according to the process conditions of Example 1. Polypropylene alloy material with plastic shrinkage rate.

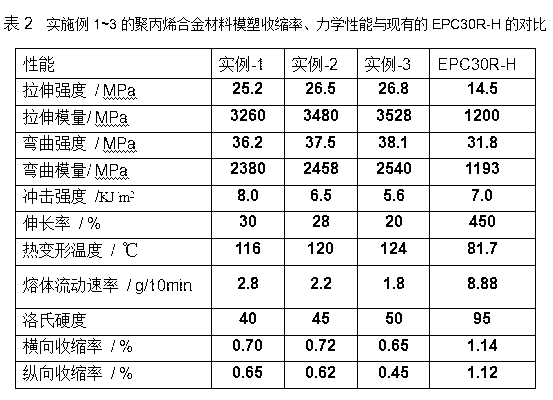

[0045] The mechanical properties and shrinkage of the polymer alloys are shown in Table 2.

Embodiment 3

[0047] According to the similar formula embodiment 3 of embodiment 1, the difference is that 50 parts of PP are added, and the grafted stearyl methacrylate basic magnesium sulfate whisker is 14 parts, which is prepared by the process conditions of embodiment 1. Polypropylene alloy material with mold shrinkage.

[0048] The mechanical properties and shrinkage of the polymer alloys are shown in Table 2.

[0049]

[0050]

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com