Method for preparing cyclic carbonate with chitosan loading type catalyst

A technology of supported catalysts and cyclic carbonates, applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve problems such as difficult separation of homogeneous catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

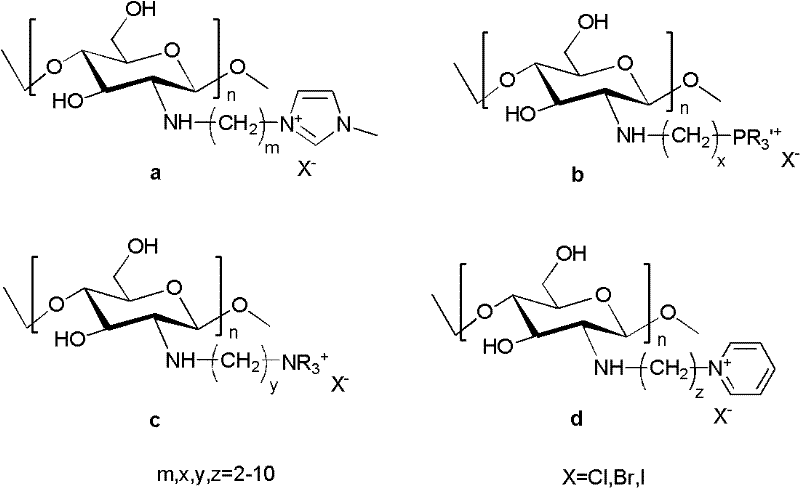

[0020] Preparation method of chitosan-loaded imidazole ionic liquid:

[0021] 1) Preparation of 1-(2-bromoethyl)-3-methylimidazolium bromide (a, m=2, X=Br) ionic liquid: In a three-necked flask, slowly drop N-methylimidazole to three Double molar equivalent of 1,2-dibromoethane was stirred at 50° C. for 24 h. After stopping the reaction, the solid product was washed with acetone and suction-filtered three times, then vacuum-dried at 50°C for 6 hours, and then used;

[0022] 2) chitosan chemical loading: 4g chitosan (deacetylation degree 80%, average molecular weight 5×10 4 ), 15g of 1-(2-bromoethyl)-3-methylimidazolium bromide aqueous solution (60wt%) and 30mL of isopropanol were added to a 100mL three-necked flask, and the reaction was stirred at 75°C for 24h. After stopping the reaction, adjust the pH value of the reaction system to 6, add ethanol to precipitate the product, wash and dry the product to obtain the product. Analysis and characterization showed that the load...

Embodiment 2

[0025] Chitosan-loaded quaternary phosphonium ionic liquid preparation method:

[0026] 1) Preparation of (3-chloropropyl)triphenylphosphonium chloride (b, x=3, R' is phenyl, X=Cl) ionic liquid: In a three-necked flask, slowly add triphenylphosphine into three Double molar equivalent of 1,3-dichloropropane, reacted with magnetic stirring at 80°C for 24h. After stopping the reaction, the solid product was washed with acetone and suction-filtered three times, then vacuum-dried at 50°C for 6 hours, and then used;

[0027] 2) chitosan chemical loading: 4g chitosan (deacetylation degree 80%, average molecular weight 5×10 4 ), 20g (3-chloropropyl) triphenylphosphonium chloride aqueous solution (80wt%) and 40mL isopropanol were added to a 100mL three-necked flask, and stirred at 80°C for 48h. After stopping the reaction, adjust the pH value of the reaction system to 7, add ethanol to precipitate the product, wash and dry the product to obtain the product. Analysis and characteriza...

Embodiment 3

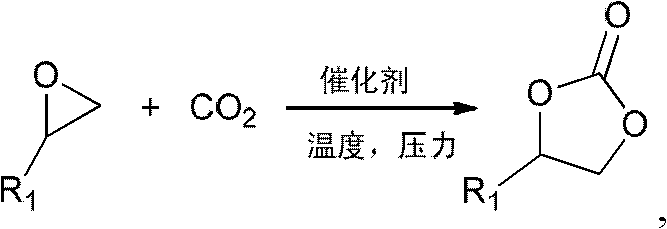

[0029]

[0030] Implementation method: in 100mL stainless steel autoclave, add the 1-methyl-3-ethyl imidazole bromide (a, m= 2, X=Br) 0.5g (1.5mmol), 10mL propylene oxide (1a) (0.14mol), a closed reaction vessel, filled with an appropriate amount of pressure CO 2 , the temperature was controlled by a temperature controller to slowly rise to 120° C., and then the reaction pressure was controlled to 2.5 MPa, and the reaction was carried out for 4 hours. After the reaction, the reactor was cooled to room temperature, and excess CO was released slowly. 2 After the catalyst was separated by filtration, the obtained product (2a) was quantitatively analyzed by a gas chromatography-mass spectrometer, the selectivity was >99.8%, and the yield was 96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com